Insulation device and method for tool cutting temperature measurement experiment

A cutting temperature and insulating device technology, which is used in measuring/indicating equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of inaccurate experimental data of cutting temperature of cutting tools, and achieve the effect of low cost, simplified structure and reliable experimental data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

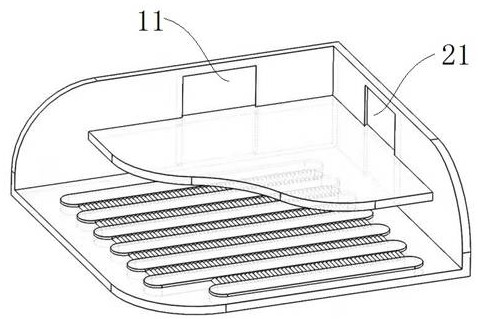

[0040] Such as figure 1 As shown, the present embodiment provides an insulating device used for cutting tool cutting temperature measurement experiment, which includes an insulating frame with an opening for accommodating the cutting tool. The insulating frame includes a vertical side panel A1 , a vertical side panel B2 , a bottom panel 3 and a movable cover panel 4 .

[0041] Among them, the vertical side plate A1 and the vertical side plate B2 are connected to each other, the bottom plate 3 is respectively connected to the vertical side plate A1 and the vertical side plate B2, and the movable cover plate 4 is movably connected to the vertical side plate A1 and the vertical side plate B2 , The bottom plate 3 is set opposite to the movable cover plate 4 .

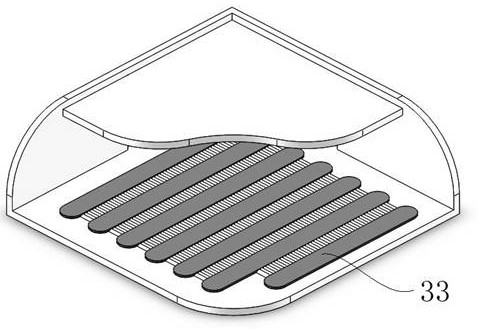

[0042]A plurality of sawtooth structures 31 are arranged on the bottom plate 3 , and the sawtooth structures 31 are distributed in a strip shape, and the plurality of sawtooth structures 31 are arranged parallel to each ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com