Embedded replaceable local exhaust device and exhaust system for experiment table

A technology of exhaust device and test bench, which is applied to cleaning methods and appliances, chemical instruments and methods, and smoke and dust removal, etc., and can solve problems such as occupying a large area, polluting gas cannot be removed in time, and has not been widely used.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Specific embodiments of the present invention are provided below, and it should be noted that the present invention is not limited to the following specific embodiments, and all equivalent transformations done on the basis of the technical solutions of the present application all fall within the scope of protection of the present invention.

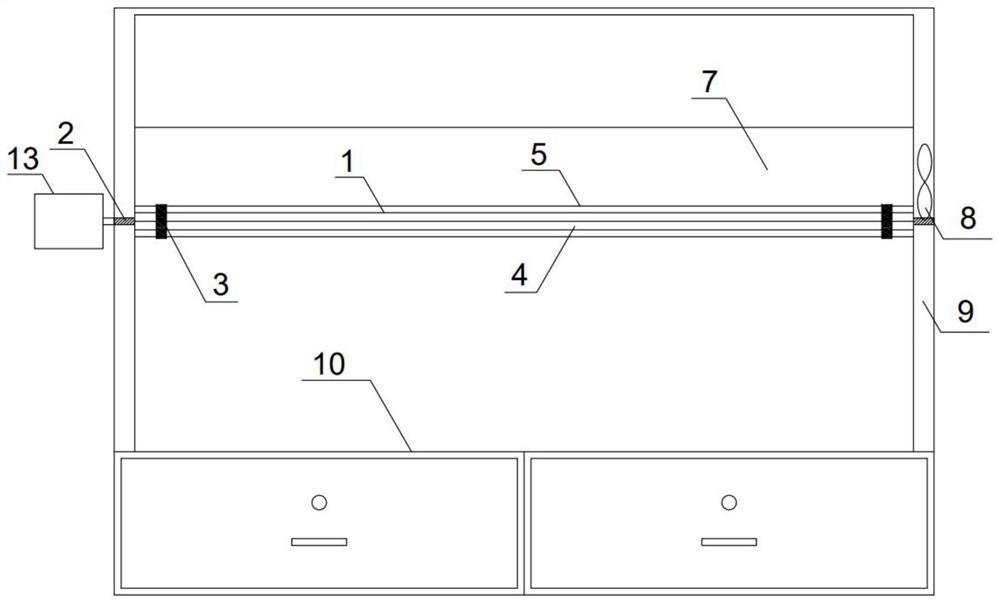

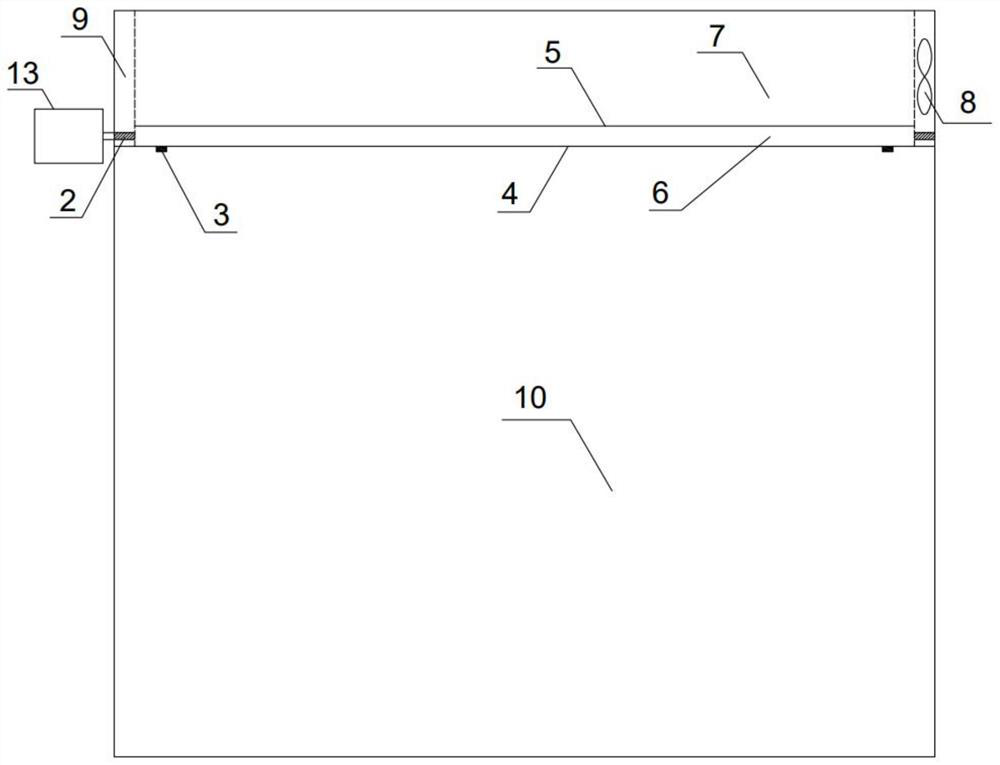

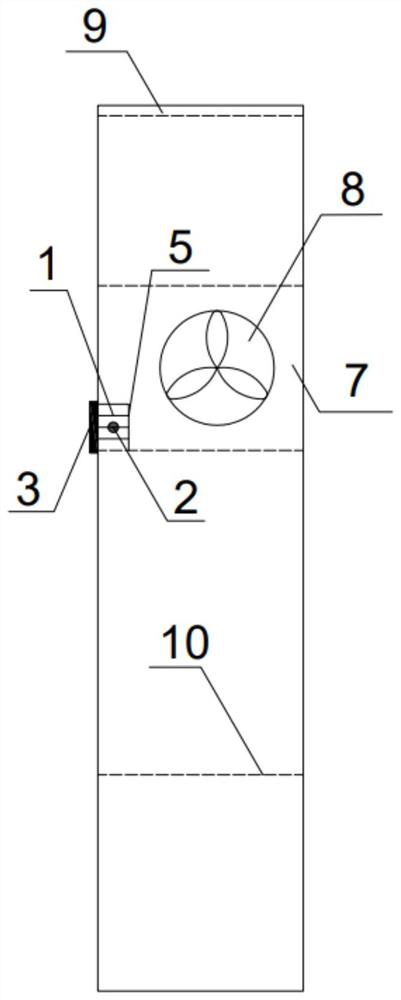

[0037] like Figure 1-Figure 3 As shown, the embodiment of the present invention provides a kind of test bench embedded replaceable local exhaust device, including the test bench reagent rack 9 on the test bench top 10, the test bench reagent rack 9 is provided with an air outlet pipe 7 and a small A local exhaust fan 8 and a local exhaust hood 6 are arranged in the air outlet pipe 7, and the local exhaust hood 6 is connected to the test bench reagent rack 9 through a protruding frame rod 2. Wherein, the air outlet pipe 7 is the cavity in the middle part of the reagent rack 9, and the air outlet pipe 7 is arranged laterally along t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com