Efficient dust treatment equipment for environmental protection of building construction site

A technology for environmental protection and dust treatment, applied in construction, use of liquid separation agents, separation methods, etc., can solve the problems of limited use range, low flexibility, poor practicability, etc., to improve the range of dust removal, improve flexibility, Ease of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

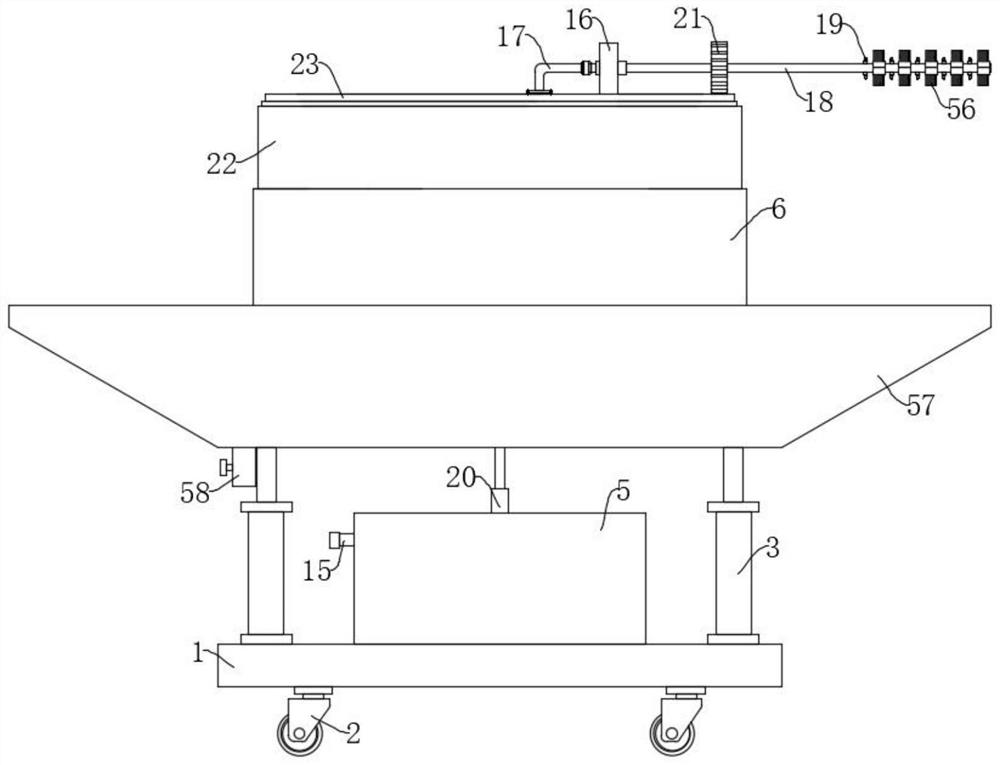

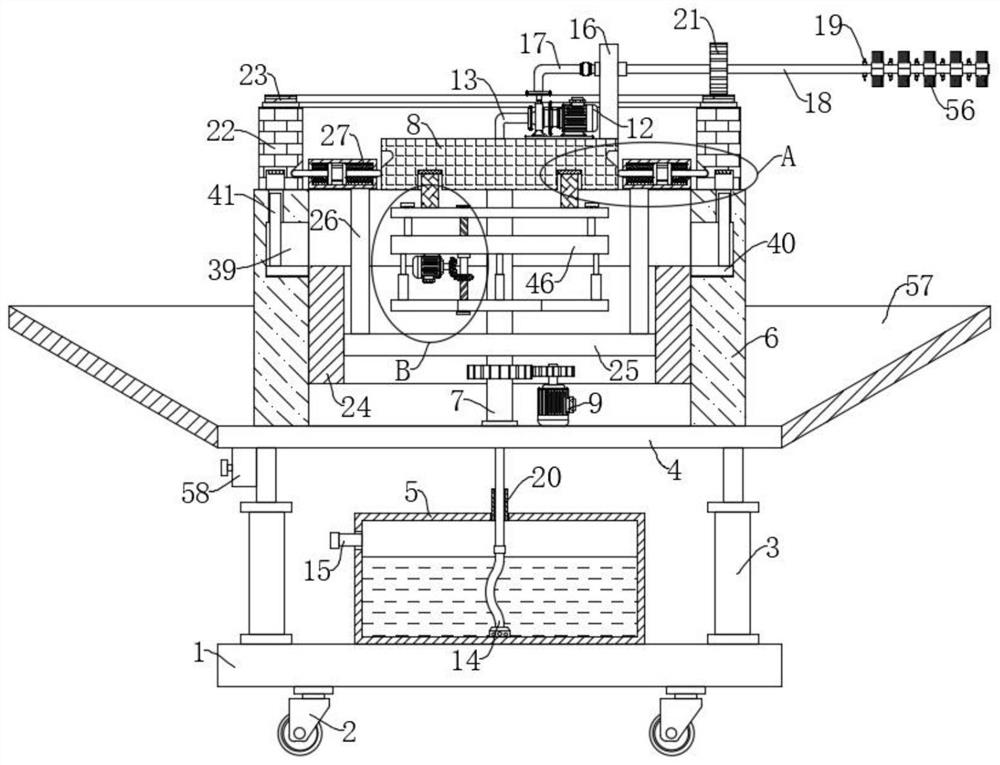

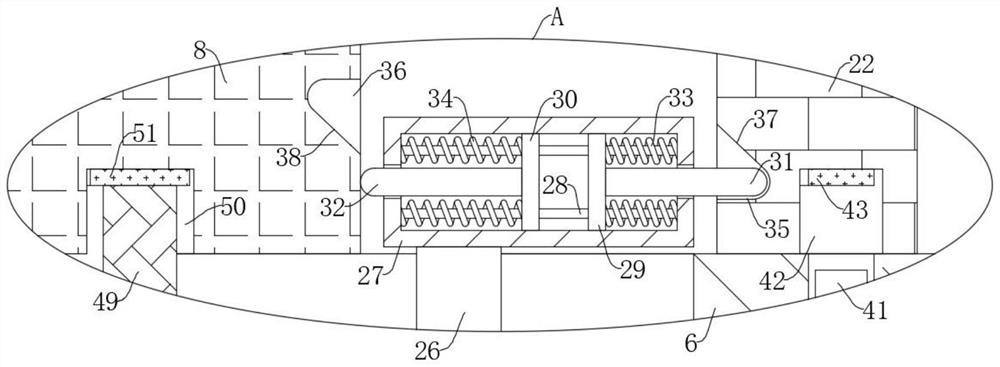

[0054] Such as Figure 1-14 As shown, a high-efficiency dust treatment equipment for environmental protection on a construction site includes a bottom plate 1, universal wheels 2 are connected to the bottom four corners of the bottom plate 1, lifting cylinders 3 are fixedly connected to the top four corners of the bottom plate 1, and four lifting cylinders The top of 3 is fixedly connected with the same support plate 4, the top of the support plate 4 is rotatably connected with a rotating tube 7, and the top of the rotating tube 7 is rotatably connected with a rotary table 8, and the top of the rotary table 8 is provided with a water spraying mechanism for sprinkling water and dust removal , the top of the support plate 4 is provided with a driving mechanism for driving the rotary table 8 to rotate, the top of the support plate 4 is fixedly connected with a fixed cylinder 6, and the top of the fixed cylinder 6 is provided with a transmission mechanism for auxiliary water sprayi...

Embodiment 2

[0060] This embodiment is as a further improvement of the previous embodiment: as Figure 1-14 As shown, a high-efficiency dust treatment equipment for environmental protection on a construction site includes a bottom plate 1, universal wheels 2 are connected to the bottom four corners of the bottom plate 1, lifting cylinders 3 are fixedly connected to the top four corners of the bottom plate 1, and four lifting cylinders The top of 3 is fixedly connected with the same support plate 4, the top of the support plate 4 is rotatably connected with a rotating tube 7, and the top of the rotating tube 7 is rotatably connected with a rotary table 8, and the top of the rotary table 8 is provided with a water spraying mechanism for sprinkling water and dust removal , the top of the support plate 4 is provided with a driving mechanism for driving the rotary table 8 to rotate, the top of the support plate 4 is fixedly connected with a fixed cylinder 6, and the top of the fixed cylinder 6 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com