Medium-sized wind power generation blade and application thereof

A wind power generation blade, medium-sized technology, applied in the direction of wind power generation, wind power engine, wind power engine consistent with the wind direction, etc., can solve the problems of inconvenient storage, transportation, weak structure strength, weak wind suction ability, etc., to achieve low Low cost mass production, easy storage and transportation, easy production and processing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

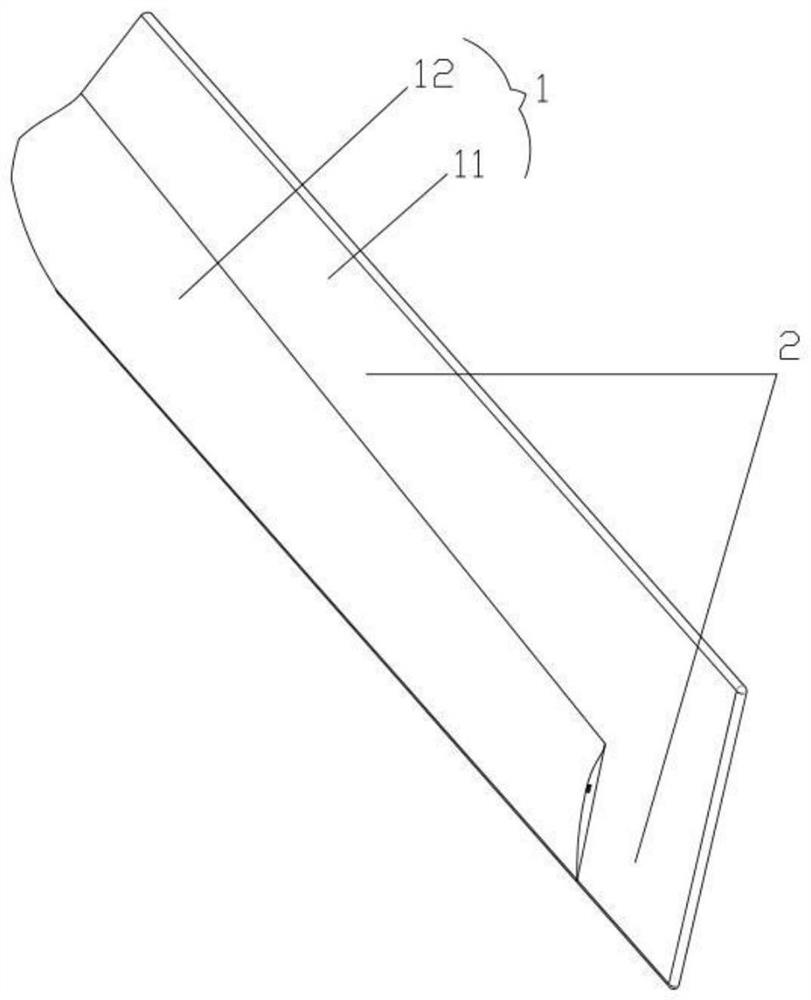

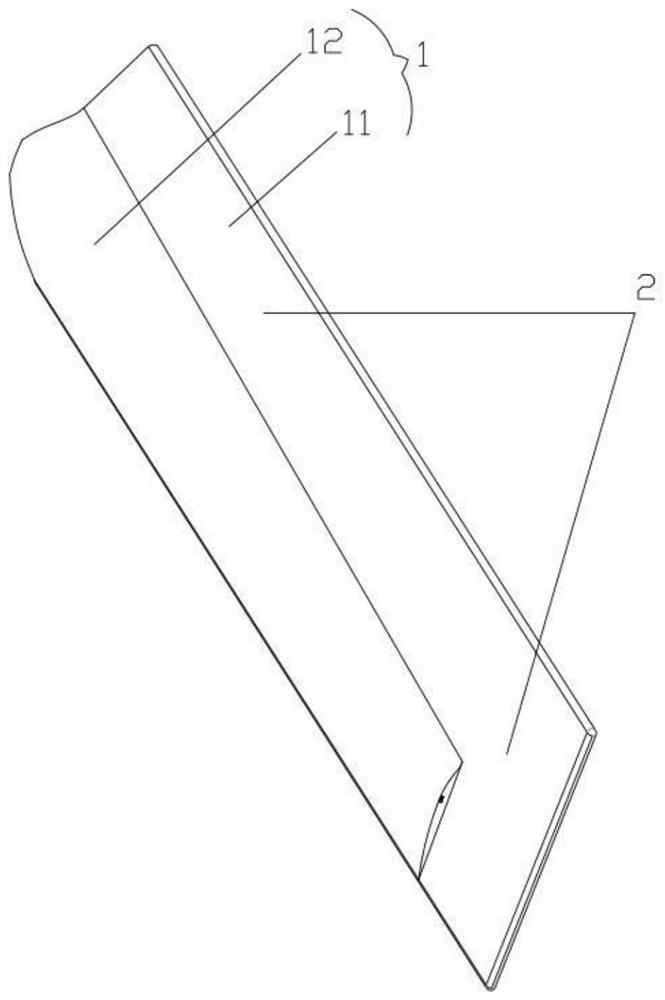

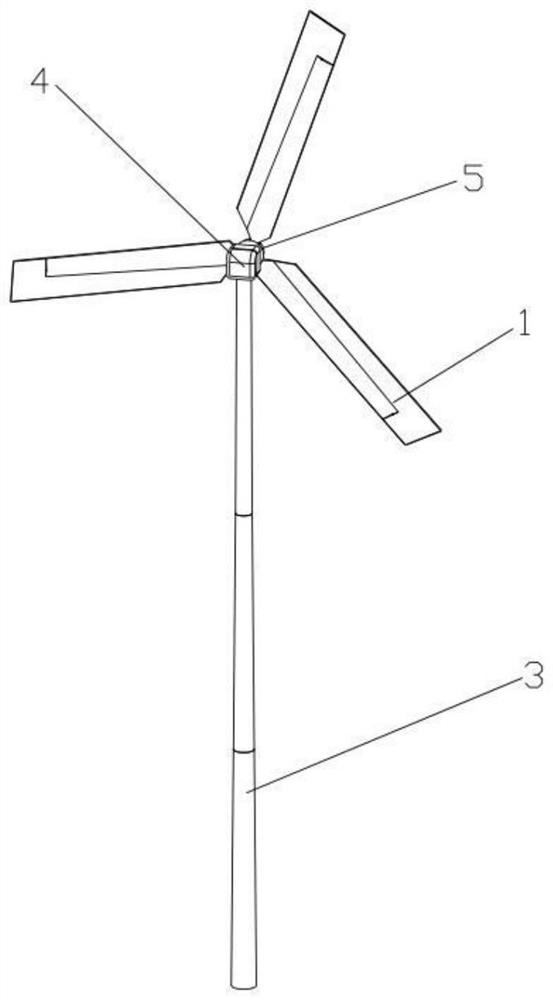

[0028] see figure 1 , 2 , a medium-sized wind power generation blade, comprising a blade body 1, and a flat plate structure 2 is arranged on the trailing edge of the blade body 1. The leading edge of the blade body 1 is also provided with a flat plate structure 2 .

[0029] The blade body 1 in this embodiment is provided with a plate structure 2 at the trailing edge, which has a larger wind receiving area, enables the blade body 1 to maximize the utilization of wind energy, and also has a higher strength, which is not easily damaged by wind force , long service life; and because of the large wind-receiving area, the blade body 1 does not need to be so long, and the length within the range of 25-30m can also meet the power generation demand, making the application of medium-sized wind power blades possible. The length of 1 is reduced, which is also convenient for the storage and transportation of the blade body. In addition, the unique design of the trailing edge of the blad...

Embodiment 2

[0035] see image 3 The difference between this embodiment and Embodiment 1 is that the thickness of the flat plate structure 2 is 100 mm, and the end of the trailing edge of the blade body 1 is a curved surface structure, which is beneficial to the greater absorption of wind force at the tail of the wind power blade, is conducive to improving the utilization rate of wind energy, and can also Ensure that the structural strength of the end of the wind power blade is high, not easily damaged by wind force, and has a long service life. The wing plate 11 is a lightweight solid metal plate, which can be an aluminum alloy plate, and the rest of the structure is the same as that of Embodiment 1.

[0036] Taking the blade body 1 with a total length of 25m and a flat plate structure 2 length of 8m as an example, test the power generation efficiency under different wind speed conditions, and compare it with the power generation efficiency of an existing common wind power blade, test and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com