Automatic stirring machine

An automatic stirring and blender technology, which is applied in the direction of blender accessories, mixers, dissolving, etc., can solve the problems of not having automatic cleaning, inconvenient cleaning for users, and cumbersome cleaning process, so as to improve convenience, stability, and easy cleaning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

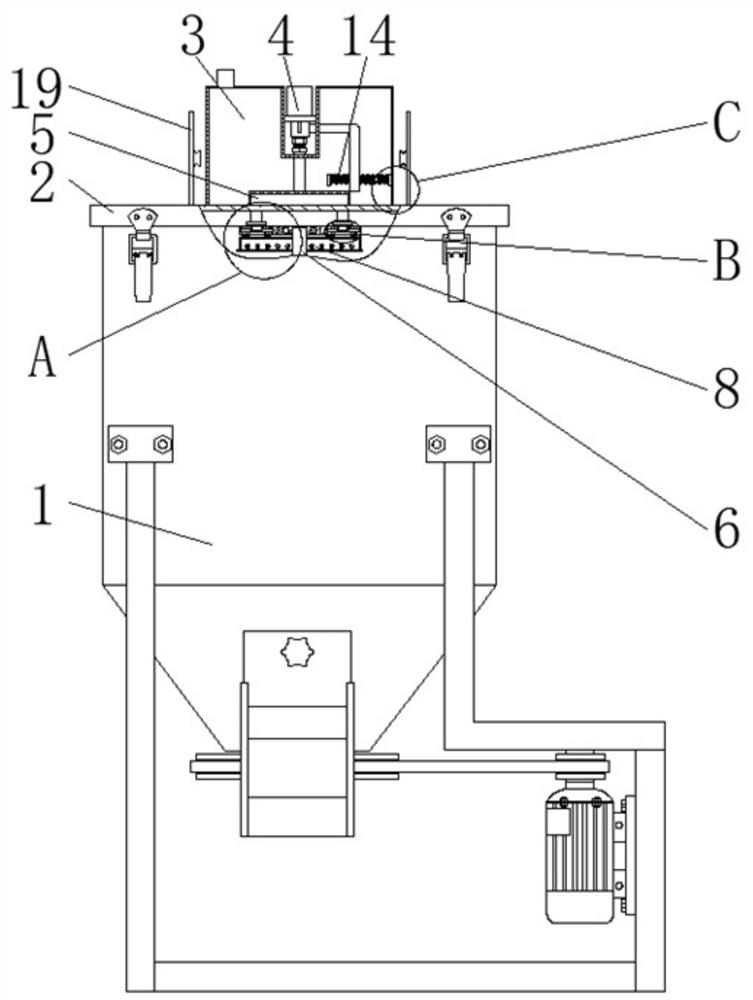

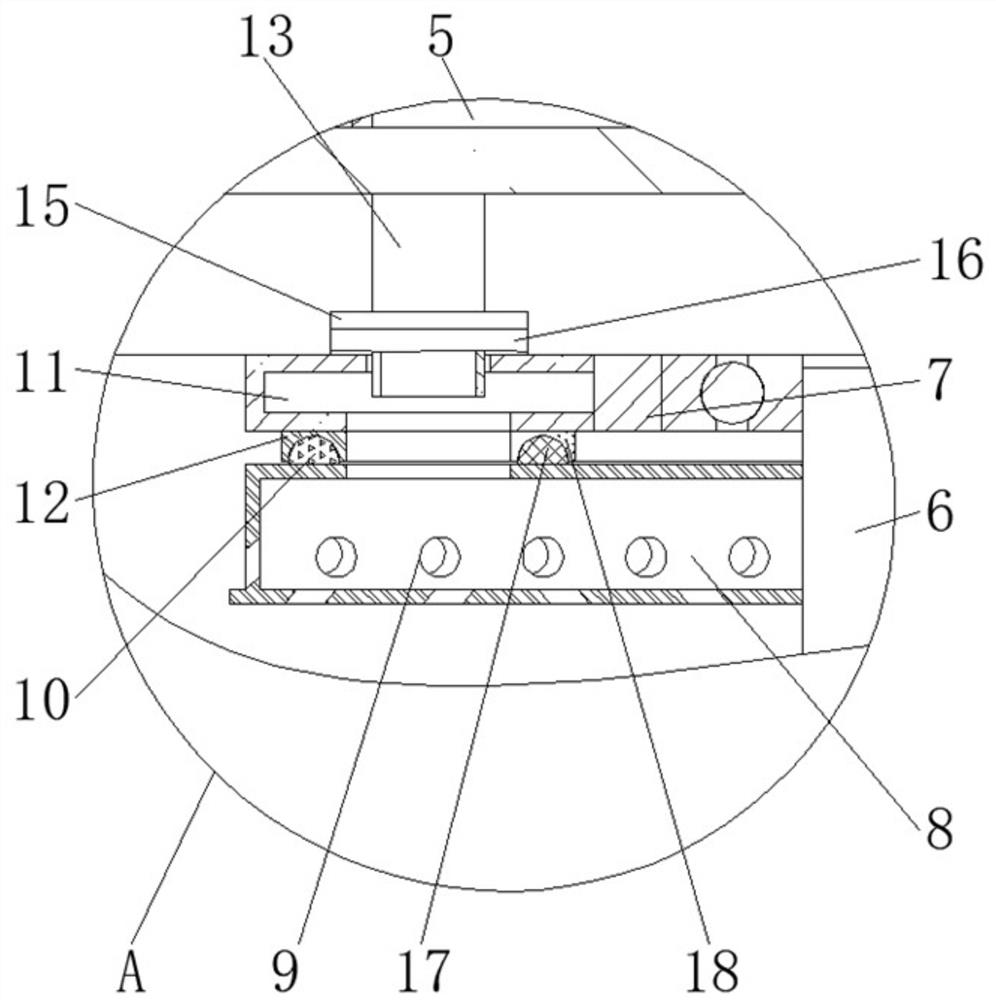

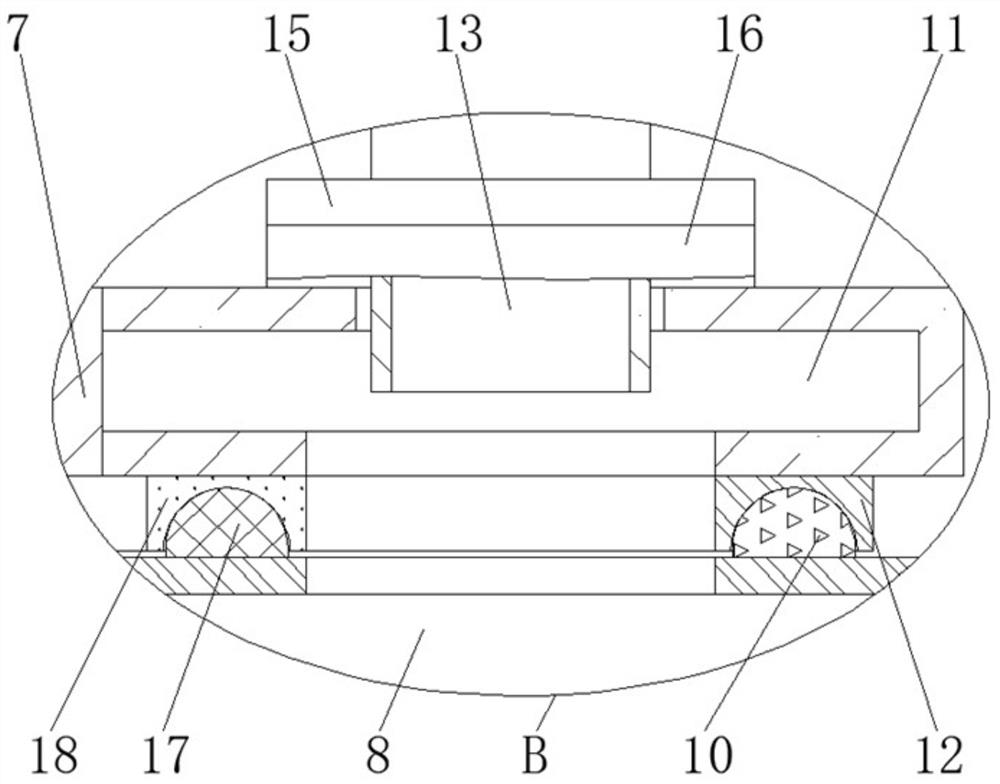

[0030] Such as Figure 1 to Figure 6 As shown, a kind of automatic mixer provided by the present invention comprises automatic stirring device 1;

[0031] The top of the automatic stirring device 1 is fixedly installed with a cover plate 2, the top of the cover plate 2 is fixedly connected with a water tank 3, the top of the water tank 3 is connected with a water pump 4, the output end of the water pump 4 is connected with the top of the water tank 3, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com