Robot cleaner

A technology for robots and cleaners, applied in vacuum cleaners, machine parts, manipulators, etc., can solve problems such as the inability of sensing to be realized correctly, limiting the sensing range of steep slope sensors, and hindering sensing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0103] Hereinafter, exemplary embodiments of the present disclosure will be described in detail with reference to the accompanying drawings, and the same or similar elements will be designated with the same reference numerals regardless of the numerals in the drawings.

[0104] In the drawings, the X-axis direction, the Y-axis direction, and the Z-axis direction are orthogonal to each other.

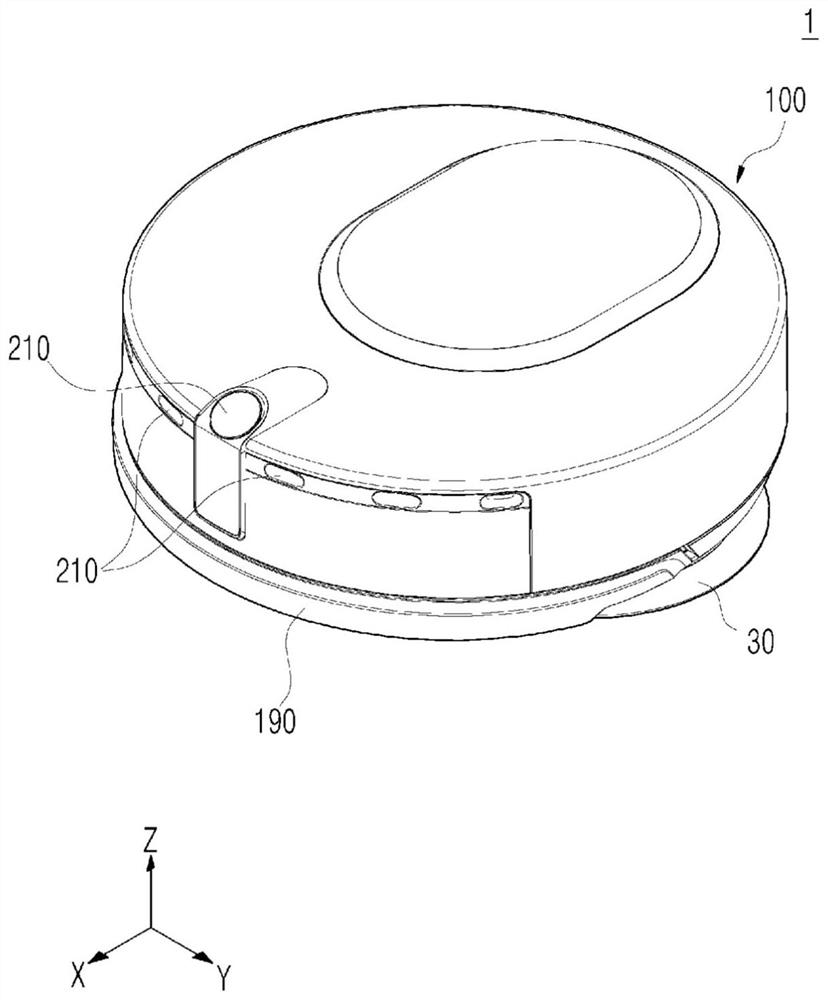

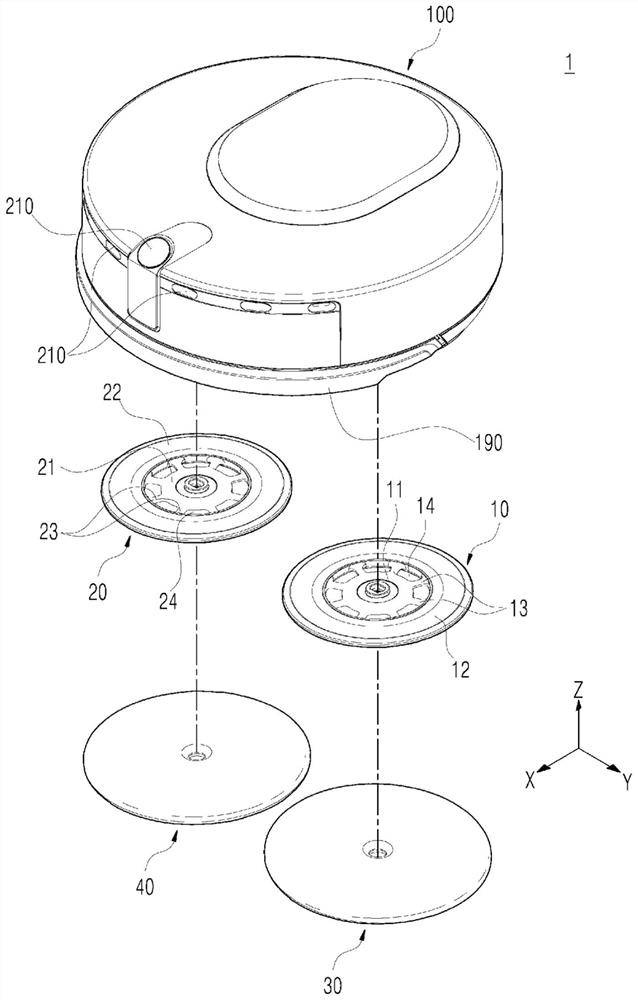

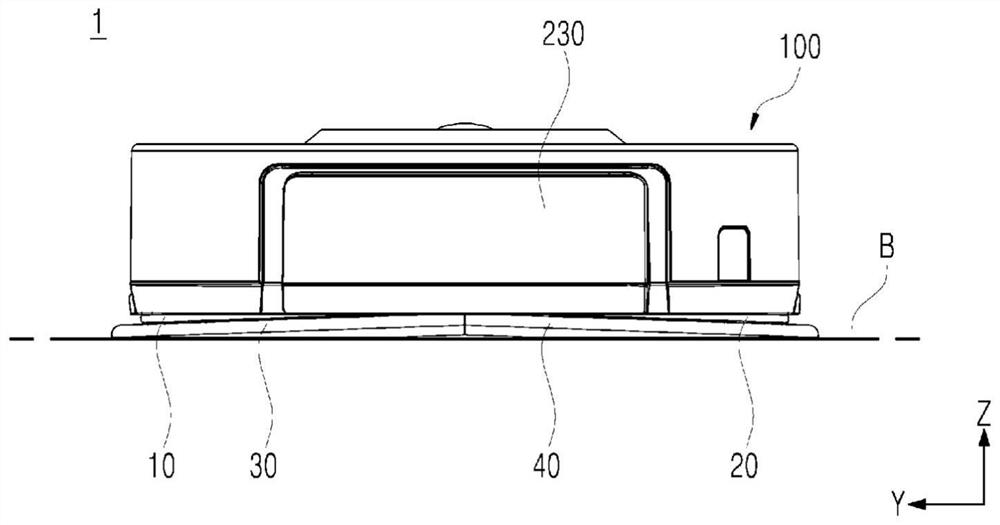

[0105] figure 1 is a perspective view illustrating a robot cleaner 1 according to some embodiments of the present disclosure. figure 2 is an illustration where some elements are separated from the figure 1 A perspective view of the robotic cleaner 1 shown in . image 3 is instantiated figure 1 The rear view of the robotic cleaner 1 shown in . Figure 4 is an illustration where some elements are separated from the image 3 The rear view of the robotic cleaner 1 shown in .

[0106]The robot cleaner 1 according to this embodiment of the present disclosure may be placed on the floor a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com