Uninterrupted power supply (UPS) device with monitoring function

A technology of power supply equipment and functions, which is applied to the structural parts of electrical equipment, emergency power supply arrangements, electrical components, etc., and can solve problems such as lack of monitoring devices, damage to load equipment, and explosions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

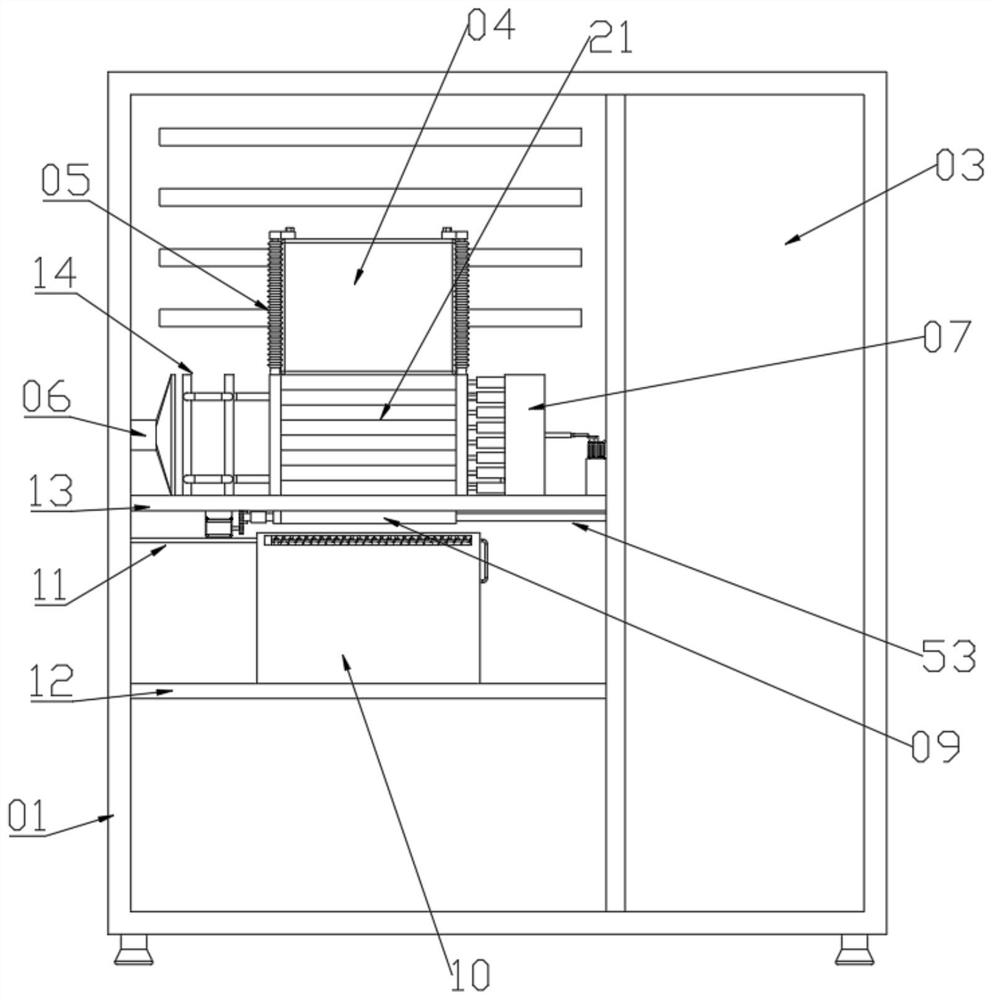

[0035] see Figure 1 to Figure 7 And the closed box 10 shown in Figure 10 to the partition board 12 in Figure 1, a kind of UPS uninterruptible power supply equipment with monitoring function, including the partition board 2 13 installed in the chassis 01, and the partition board 2 13 is fixedly connected with three diversion columns 2 19 And one guide post 18, and three guide posts 19 and guide post 18 form a rectangle, and between each guide post 19 and between guide post 18 and guide post 2 19 Both are provided with heat-absorbing strips 21 and cooling liquid is arranged in the heat-absorbing strips 21, and the heat-absorbing strips 21 are connected with the second guide column 19, but only the heat-absorbing strip 21 on one side is connected with the guide column one 18, and there is no The heat-absorbing bar 21 of one side being communicated with diversion post-18 is communicated with communicating pipe-32, and heat-absorbing bar 21 is the material of softness, and the rec...

Embodiment 2

[0039] see Figure 1 to Figure 7 And the closed box 10 shown in the figure, on the basis of the first embodiment, further, the diversion column one 18 is connected with the connecting pipe two 33, the connecting pipe two 33 is connected with the piston cylinder 27, and the piston cylinder 27 is connected with the piston box 07, A piston plate 36 is slidably connected in the piston box 07, and a piston rod 37 is fixedly connected to the piston plate 36. A one-way valve 35 with a circulation direction facing the inside of the piston cylinder 27 and away from the side of the piston plate 36 is provided on the top. The second guide tube 16 on the piston box 07 is connected with the heat dissipation orifice 14, and the heat dissipation orifice 14 is far away from the One side of the communication position with the diversion tube 2 16 is connected with the diversion tube 1 15, and the end of the diversion tube 15 away from the cooling orifice 14 is connected to the diversion column ...

Embodiment 3

[0043] see Figure 1 to Figure 8 , On the basis of the second embodiment, further, an air inlet plate 17 is provided at the position facing the cooling orifice plate 14 on the second partition plate 13, and the air inlet plate 17 is connected with the air duct 06, and the air duct 06 passes through a The support ring is fixedly connected with a motor one 22, and the output shaft of the motor one 22 is fixedly connected with a fan blade for drawing air outside the chassis 01.

[0044] When the heat dissipation orifice plate 14 quickly volatilizes the heat of the coolant into the air, the motor one 22 will drive the fan blades to rotate, thereby drawing the airflow from the direction of the air inlet plate 17 to the direction of the air cylinder 06, thereby absorbing heat The air quickly discharges from the chassis 01, thereby reducing the temperature in the chassis 01, thereby ensuring the efficiency of heat dissipation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com