Superconducting cable laying system

A technology of superconducting cables and cables, which is applied in the direction of cable laying equipment, superconducting devices, superconducting/high conducting conductors, etc., and can solve problems such as extremely high requirements for vacuum insulation of cable insulation tubes, cable scrapping, and degradation of superconducting performance , to achieve the effect of reducing the risk of external damage accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to better understand the technical solutions of the present invention, the following specific examples are described in detail:

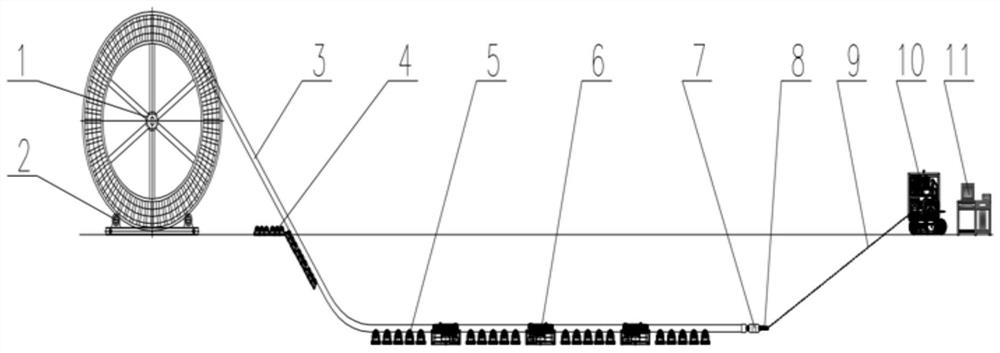

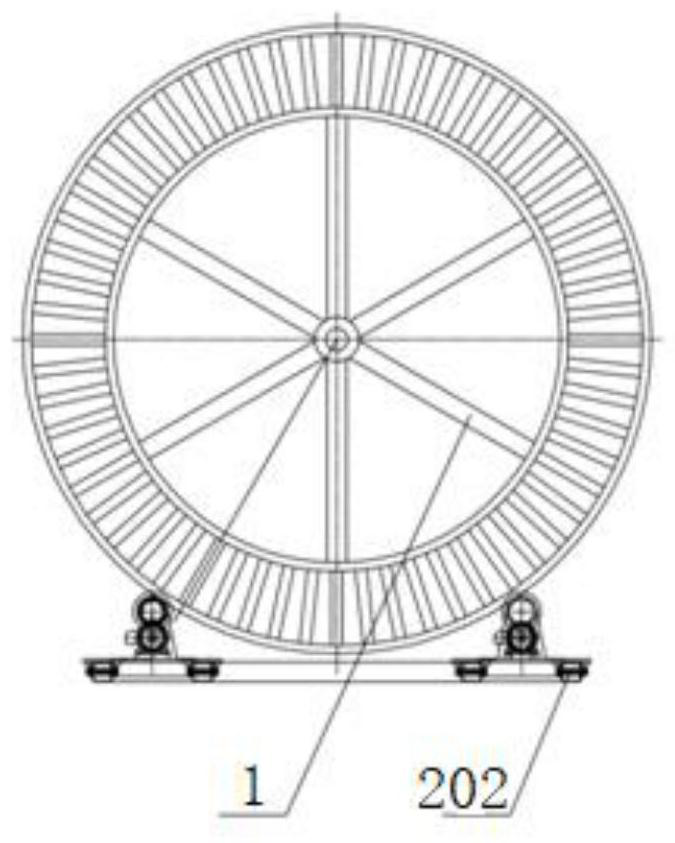

[0016] see Figure 1 to Figure 3 , a superconducting cable laying system of the present invention includes a cable reel 1, a cable reel driving device 2, a corner cable pulley 4, a cable pulley 5, a cable conveyor 6, a sensor puller 7, a rotary connector 8, Traction wire rope 9 , hydraulic winch 10 and intelligent monitoring system 11 .

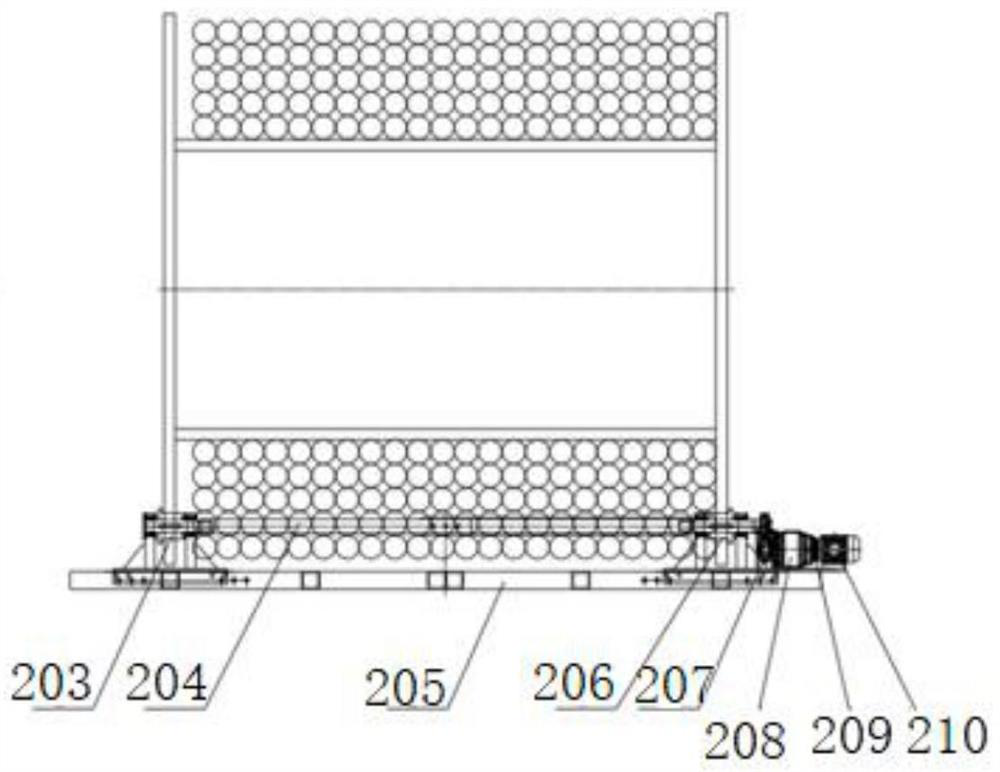

[0017] The cable reel driving device 2 is installed on the base 205 of the cable reel 1 through the connecting pins 202 . The cable spool drive arrangement includes a power assembly, a driving roller 206 , a connecting shaft 204 and a driven roller 203 . The power assembly is connected to the driving roller 206 through a gear transmission pair 207, and the connecting shaft 204 connects the driving roller 206 and the driven roller 203. The driving roller 206 and the driven roller 203 are located on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com