An Assembled Shock Absorbing Pressure Anchor and Construction Method

A kind of pressure anchoring, assembled technology, applied in excavation, infrastructure engineering, construction and other directions, can solve the problems of single structure and function, damage to prestress, bolt fracture, etc., to reduce production costs, save resources, guarantee The effect of the anchoring effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

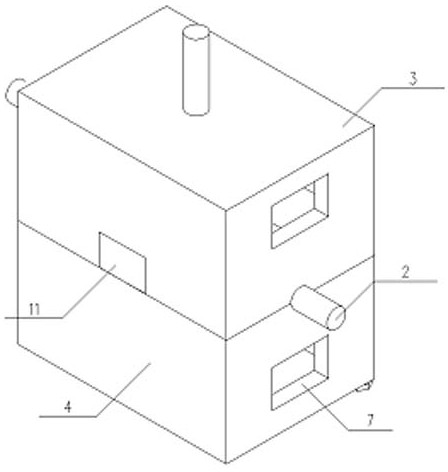

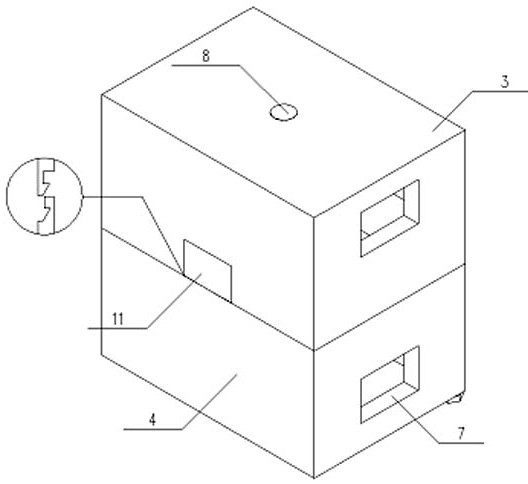

Image

Examples

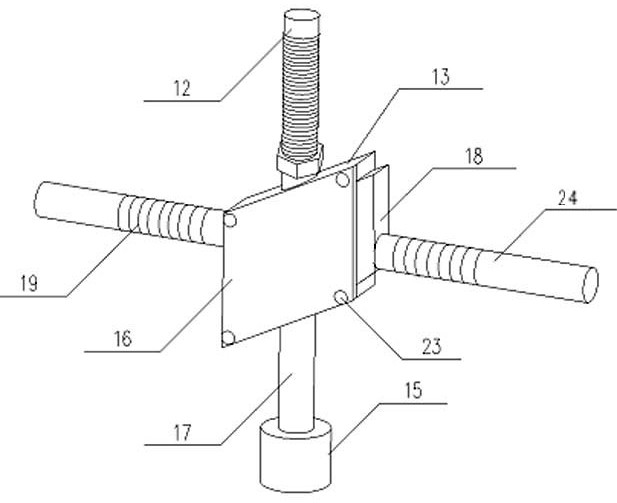

Embodiment Construction

[0017] The working principle of the present invention: ①The present invention realizes the conversion of horizontal displacement and lateral displacement through the cooperative work of two oblique contact surfaces, and realizes the restraint of lateral displacement and the recovery after stress through the spring, so that the structure is under stress Afterwards, the original state can be restored by the spring. The structure has been prestressed before work, the sleeve is connected with the anchor rod, and the anchor rod is pulled by the restoring force of the spring of the lateral shock absorbing device to realize the anchoring function. ② Assembled shock-absorbing relief anchorage, the load is transmitted to the vertical shock-absorbing relief device through the sleeve. When the surrounding rock deforms greatly, the vertical displacement is converted into lateral displacement through the displacement conversion between the slopes to realize With pressure function. ③ Assem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com