Method and device for rolling translation of cylinder equipment

An equipment and cylinder technology, which is applied in the field of rolling and translation of cylinder equipment, can solve the problems of subsidence and stuck, equipment paint wear and paint loss, and many times of hook and hook removal, etc., and achieve the effect of reducing friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

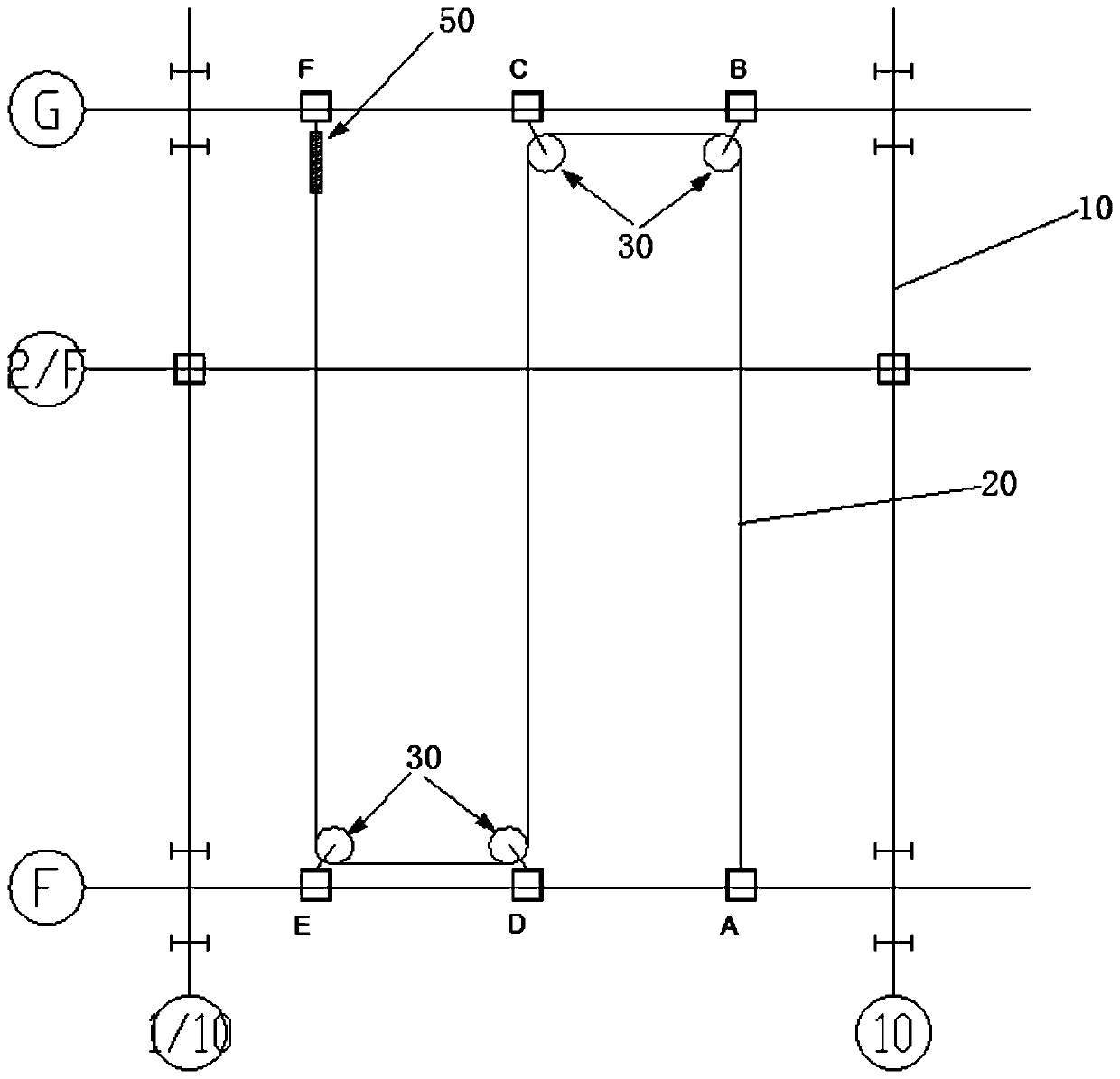

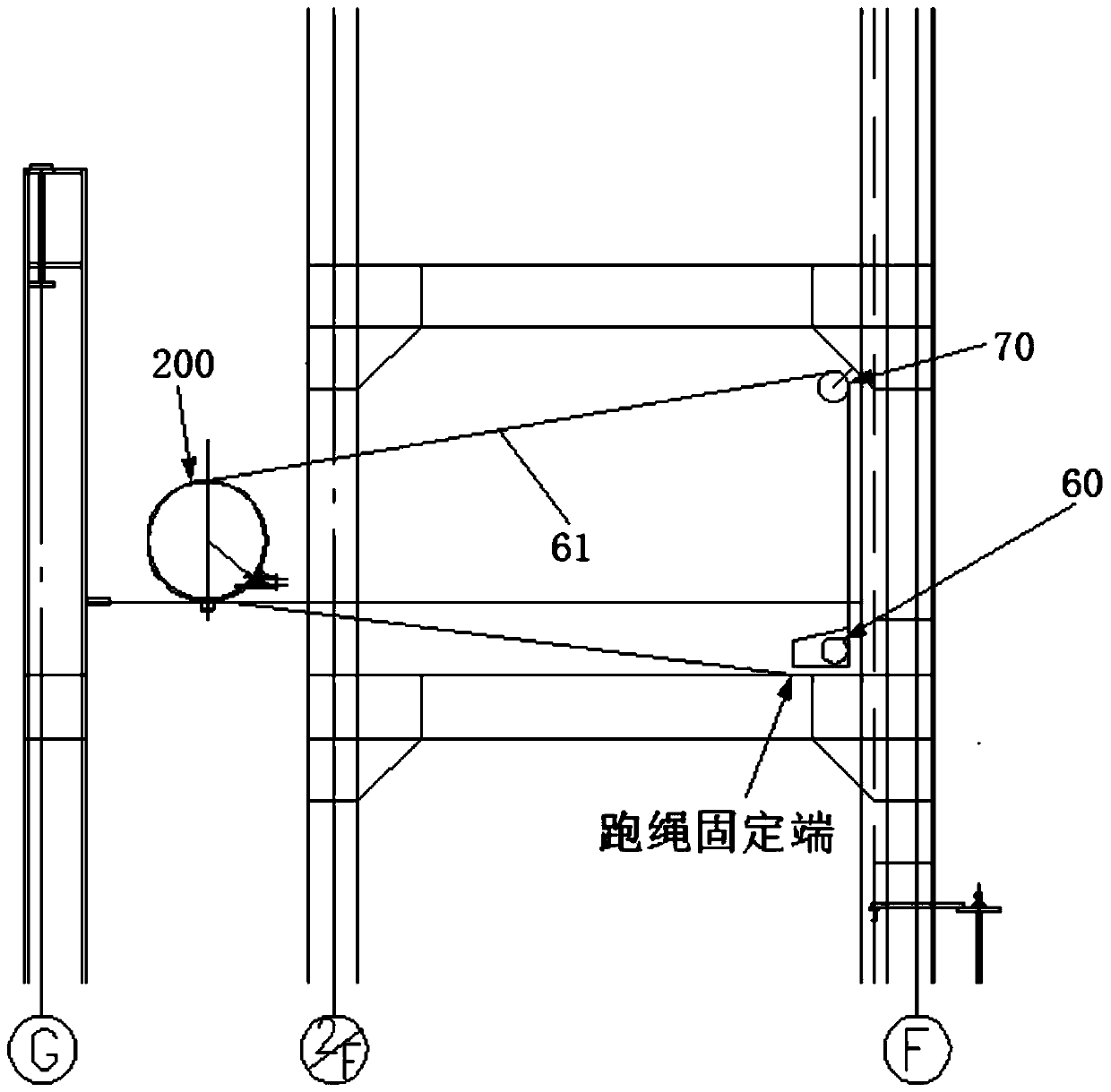

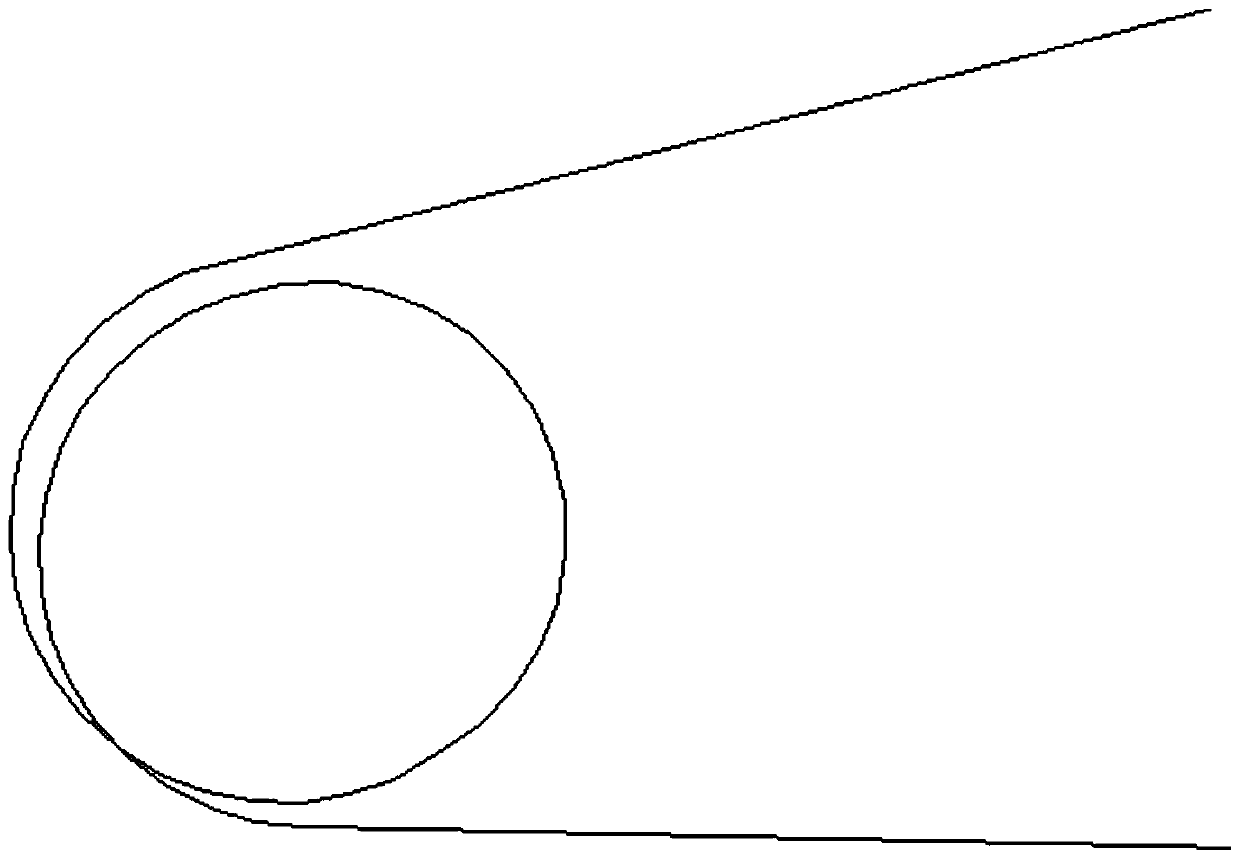

[0026] like Figure 1-4 As shown, the present invention proposes a method for rolling translation of cylinder equipment, which belongs to the hoisting method for translation of large cylinder equipment, and its main content is to hang three or more parallel steel wire ropes 20 between two rows of workshop columns and pull Put the large cylinder equipment 200 on the parallel steel wire rope 20, and pull the two ends of the cylinder equipment 200 simultaneously to make the cylinder equipment 200 roll on the parallel steel wire rope 20 to reach the designated position. The hoisting method of the present invention is different from traditional relay hoisting and platform sliding, and its operation is simpler. The method sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com