Building engineering quality plane detection system

A detection system and construction engineering technology, applied in measuring devices, instruments, and fluid devices, etc., can solve problems such as surface flatness detection of difficult construction projects, and achieve the effect of large detection range, accurate and comprehensive detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, goals and functions achieved by the present invention clearer and easier to understand, the present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments:

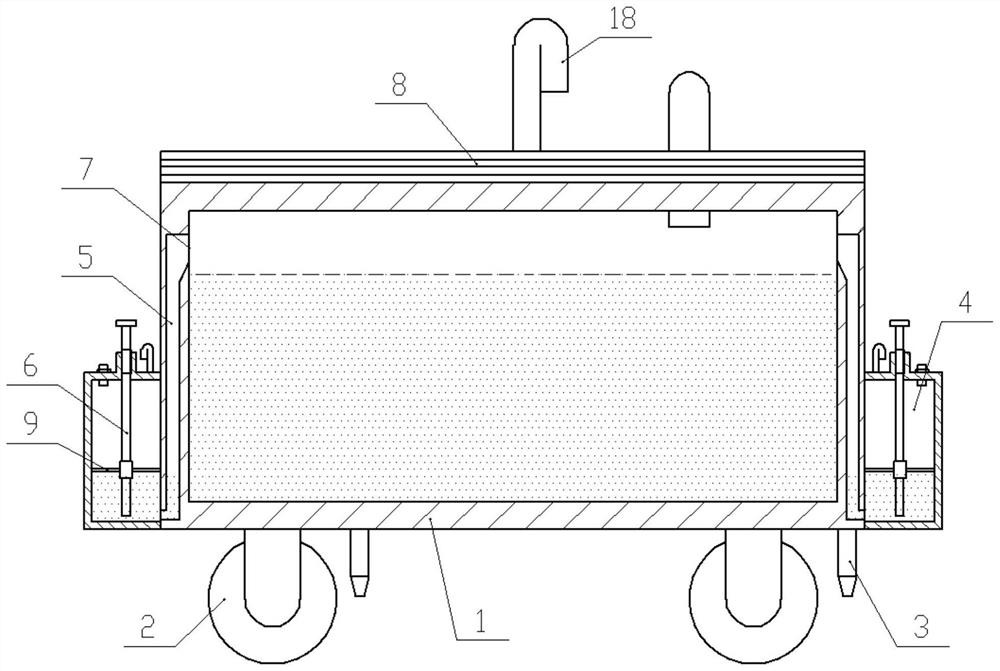

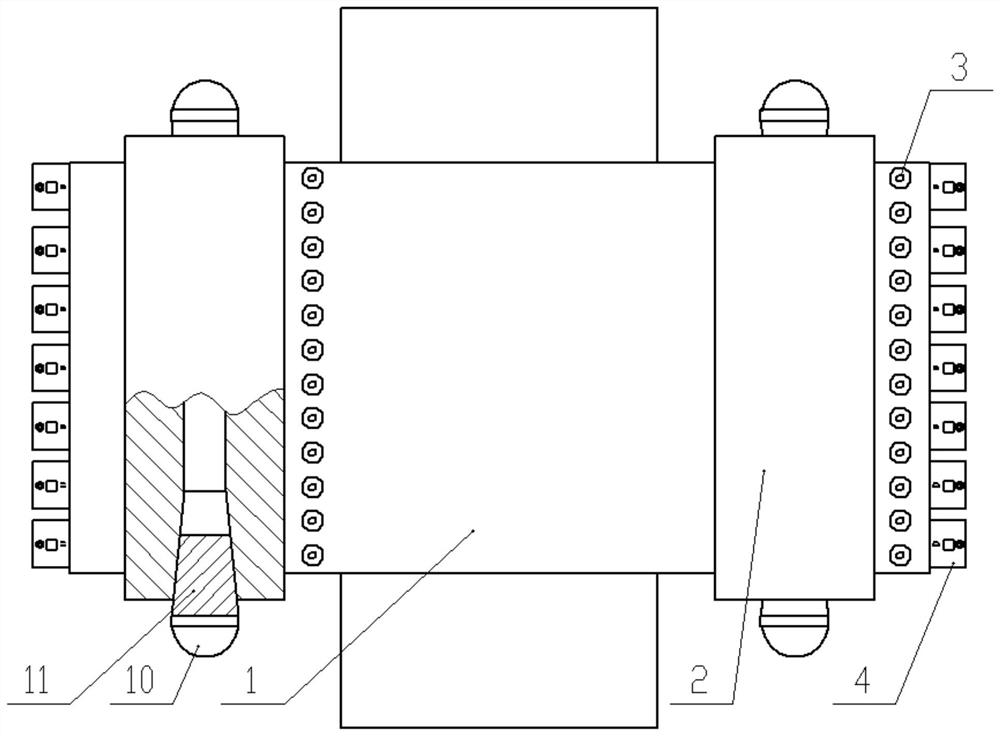

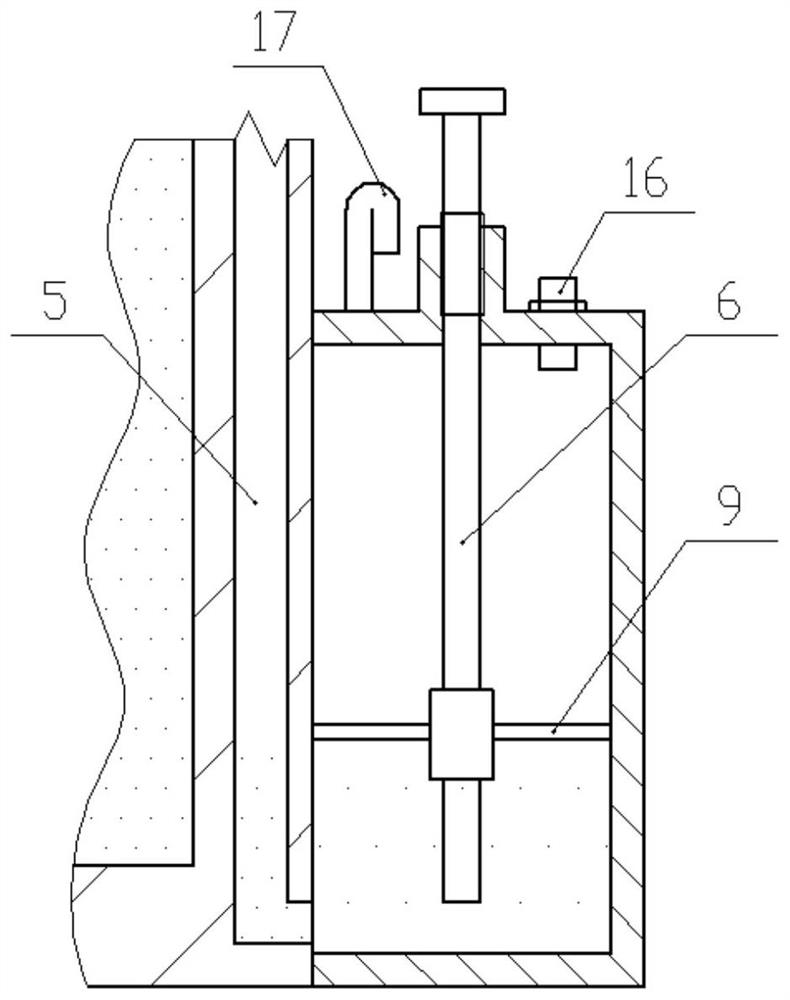

[0018] Such as Figure 1-2 As shown, the present invention proposes a construction engineering quality level inspection system, which mainly includes a water storage tank 1, and the water storage tank 1 is filled with a measurement liquid, such as water or oil. A roller 2 is respectively installed at the front and rear ends of the bottom of the water storage tank 1, the surface of the roller 2 is smooth, and it can roll on the corresponding surface of the building, and with figure 1 The orientation shown is installed at both ends of the drum 2, and the two ends of the drum 2 should respectively protrude from the left and right sides of the water storage tank 1, so that the drum 2 can contact a wider r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com