Desulfurization equipment for natural gas exploitation

A desulfurization equipment, natural gas technology, applied in lighting and heating equipment, gas fuel, gas treatment, etc., can solve the problem of low desulfurization efficiency, achieve the effect of improving desulfurization efficiency and strengthening dehydration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

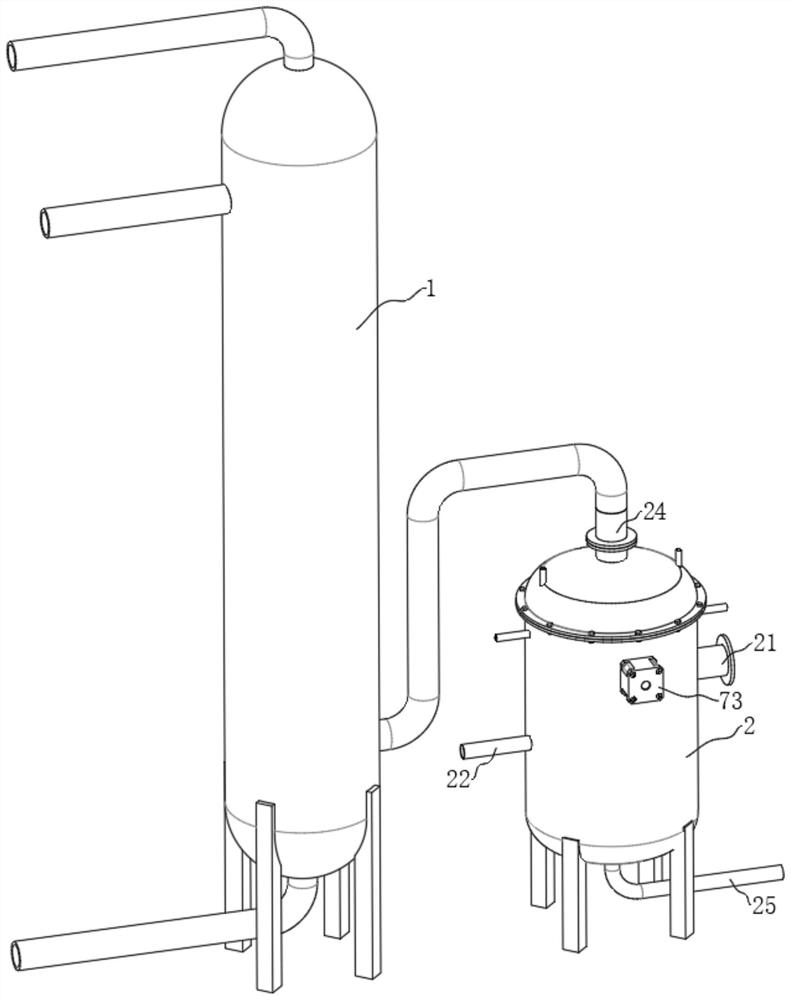

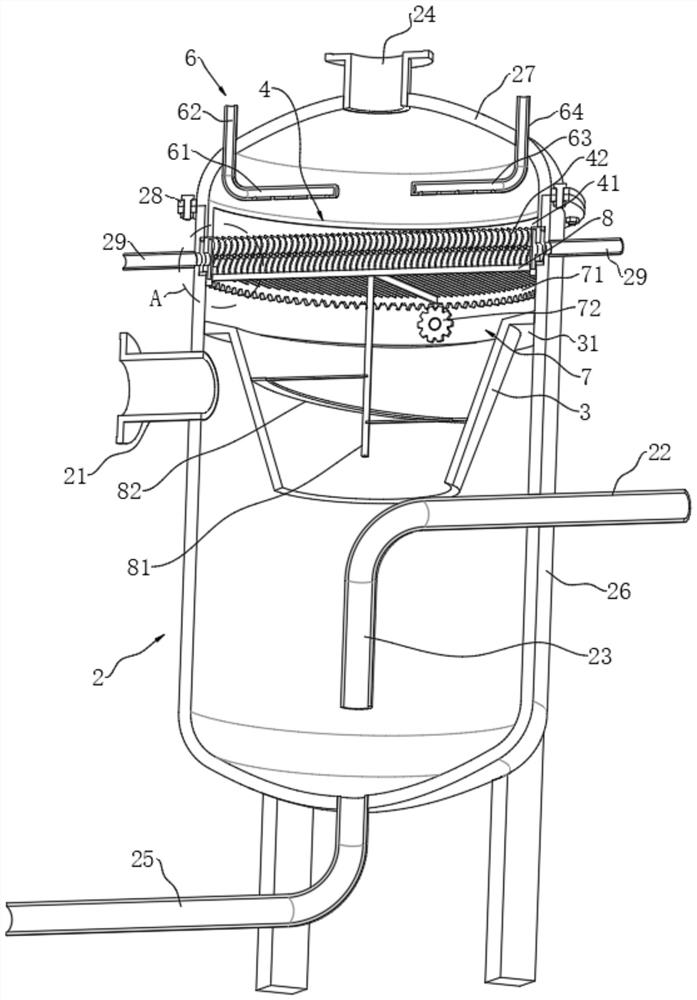

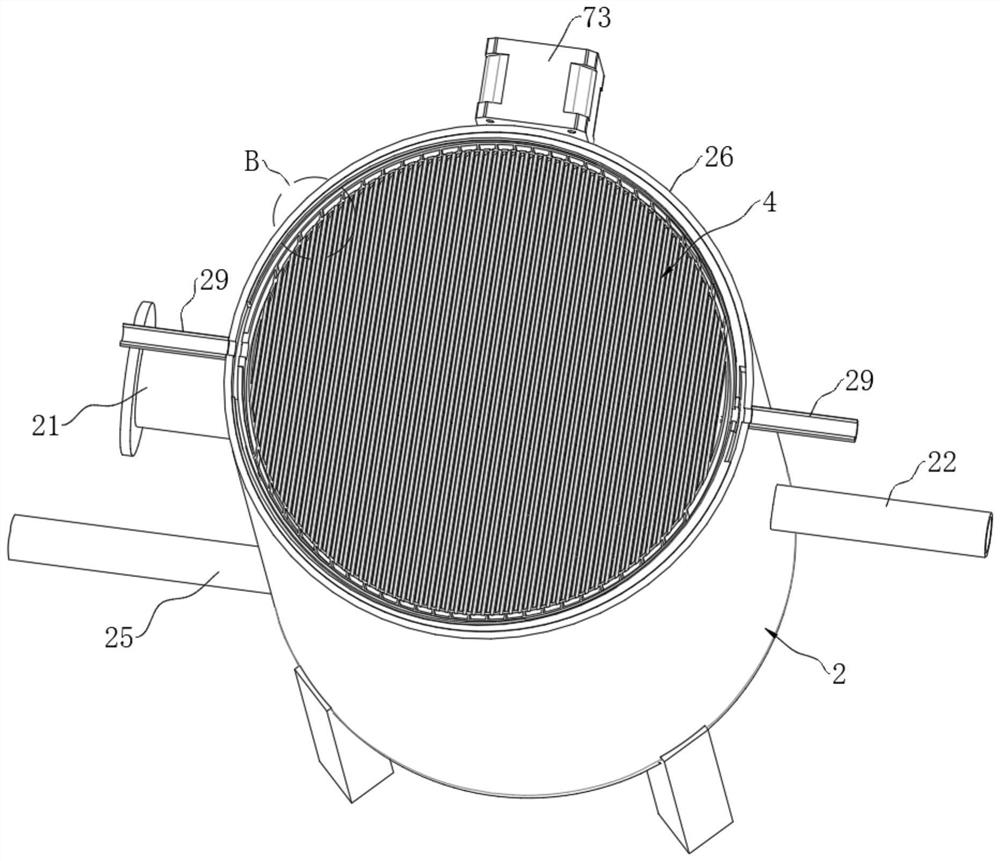

[0025] The disclosure of the embodiment of the present application provides a desulfurization equipment for natural gas development. By setting the gas-water separation tower 2, the natural gas can be pretreated before the natural gas enters the desulfurization tower 1, the purity of the natural gas can be improved, and the gas-water separation tower 2 can be used. The liquid and solid particles contained in the natural gas are greatly reduced to facilitate the desulfurization treatment in the desulfurization tower 1, which solves the problem of low desulfurization efficiency caused by the liquid contained in the natural gas in the prior art, and realizes the reduction of the liquid contained in the natural gas before the desulfurization treatment and solid particles to improve the desulfurization efficiency of natural gas.

[0026] In order to better understand the above-mentioned technical solution, the above-mentioned technical solution will be described in detail below in c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com