Automatic stacking device for corrugated cartons

A technology of automatic stacking and corrugated boxes, applied in the directions of transportation and packaging, thin material handling, sending objects, etc., can solve the problems of inconvenient cardboard sampling inspection and poor effect, and achieve the effect of improving convenience and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

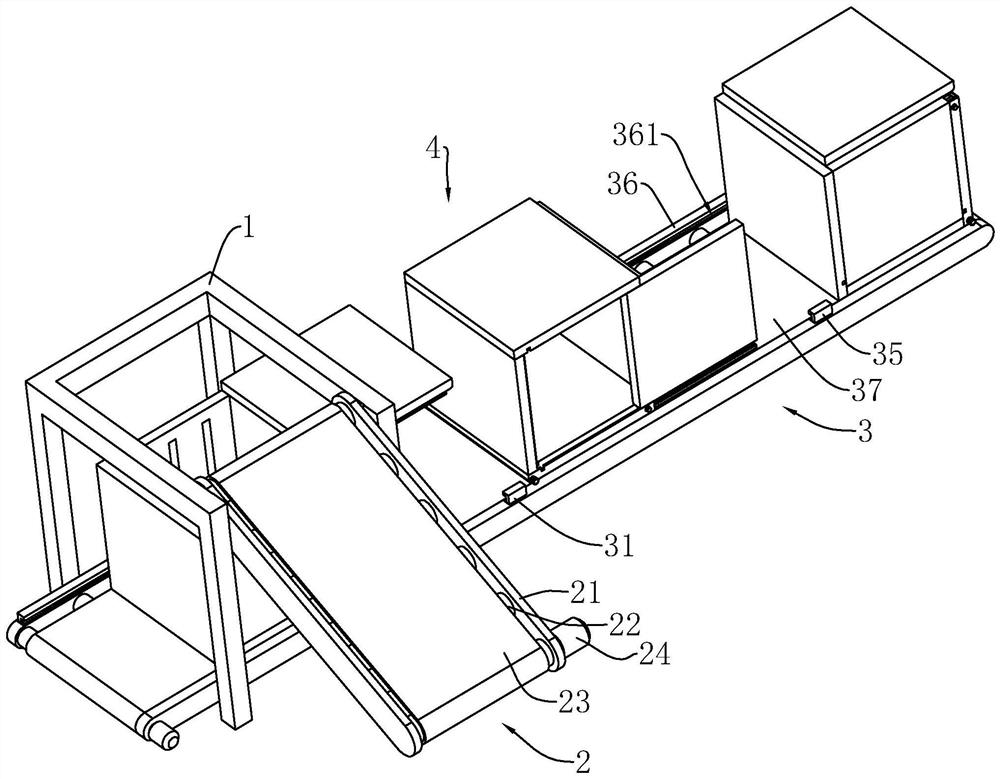

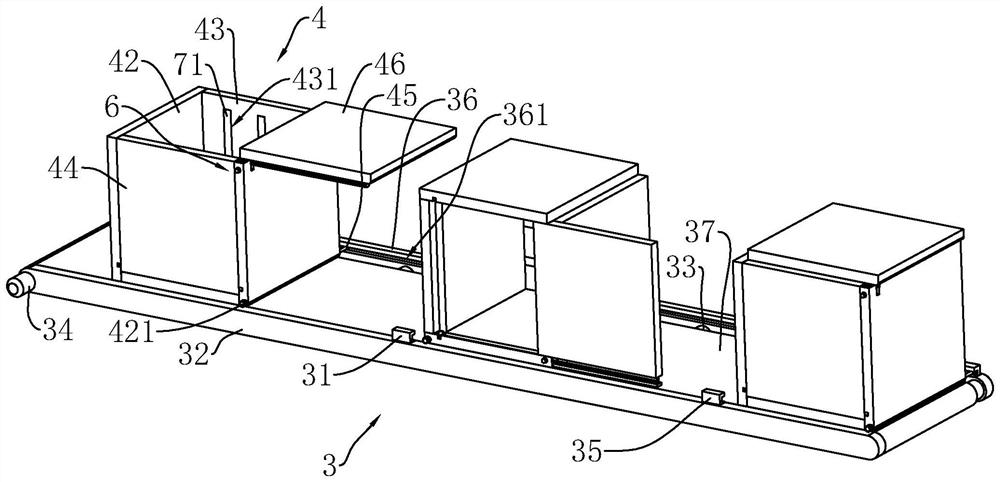

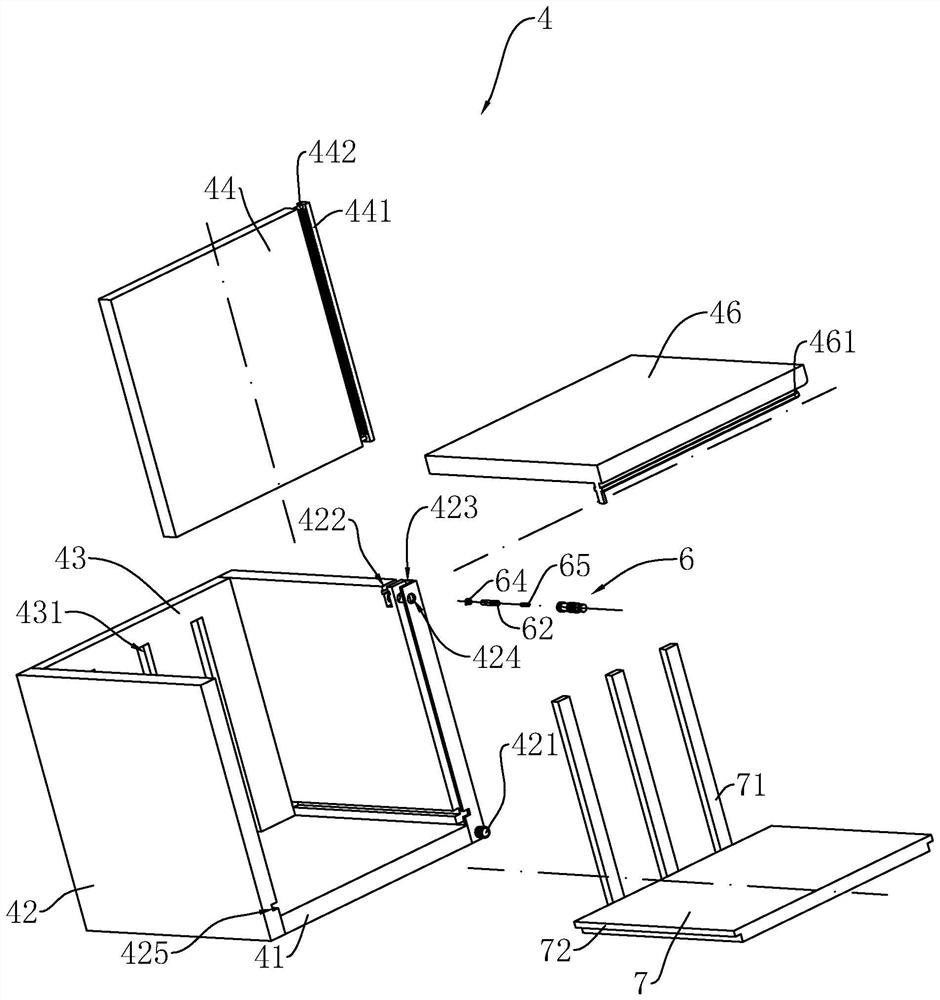

[0035] The following is attached Figure 1-5 The application is described in further detail.

[0036] The embodiment of the application discloses an automatic stacking device for corrugated cardboard boxes.

[0037] refer to figure 1 and figure 2 , an automatic stacking device for corrugated boxes, including a frame 1, a conveying mechanism 2 is arranged on one side of the frame 1, and the conveying mechanism 2 includes two conveying frames 21, a plurality of conveying rollers 22, a conveying belt 23, and a conveying motor 24 Two conveying racks 21 are spaced apart and fixedly connected to one side of the frame 1 in parallel, and a plurality of conveying rollers 23 are spaced apart along the length direction of the conveying rack 22 and parallelly rotated to connect between the opposite side walls of the two conveying racks 21. The conveying rollers 22 The quantity is selected according to the length of the carriage 21 . A plurality of conveying rollers 22 are connected b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com