Integrated hot melting process of seat cushion

A technology of heat welding and seat cushion, which is applied in the field of integrated heat welding process of seat cushion, which can solve the problems of unsightly appearance, poor assembly firmness, and surface peeling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The drawings of the preferred embodiments of the present invention are further described below in order to enable those skilled in the art to implement according to the statements in this specification.

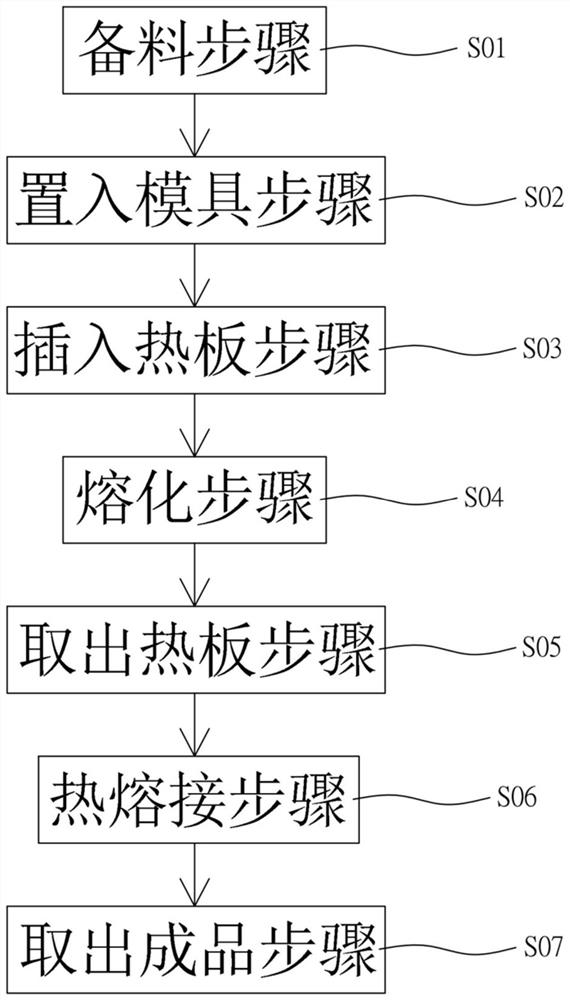

[0040] First, see Figure 1 to Figure 11 As shown, the present invention is an integrated thermal welding process of a seat cushion, comprising: the following steps:

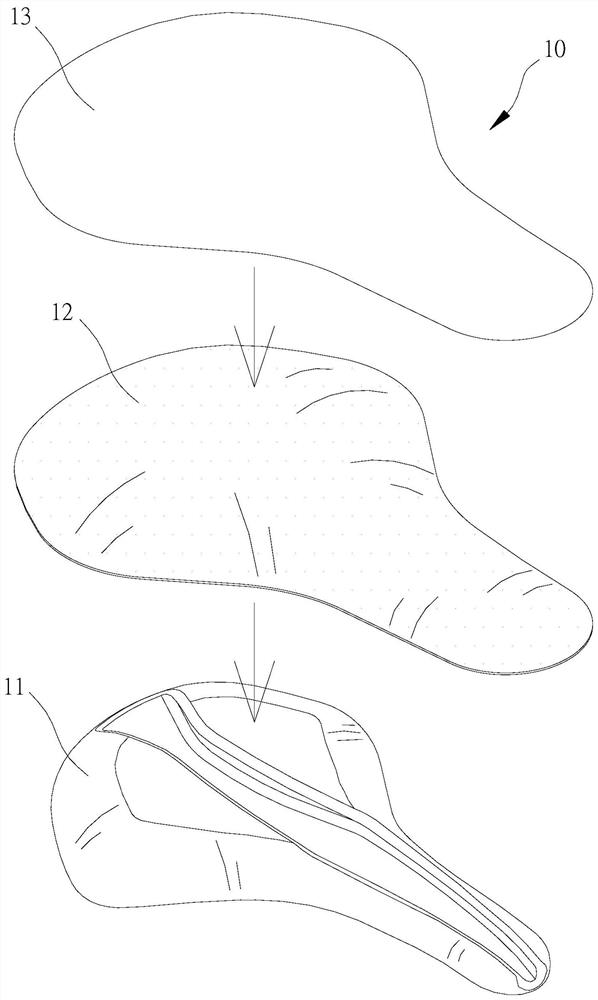

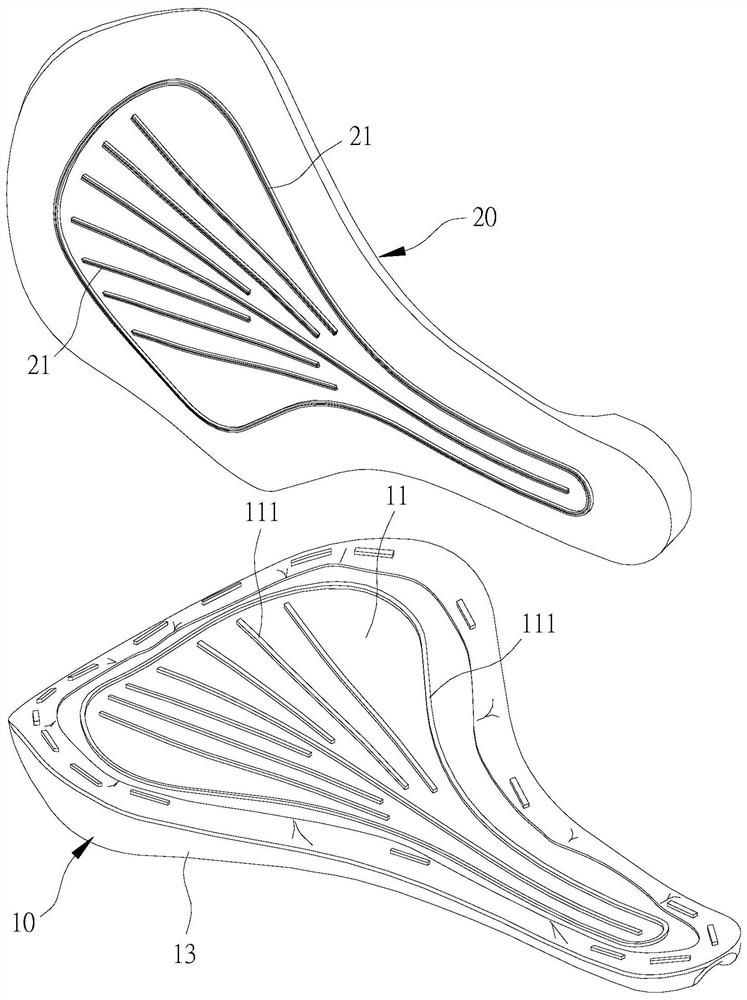

[0041] (a) Material preparation step S01: prepare a seat cushion body 10 and a bottom shell layer 20, the seat cushion body 10 is fixed on a rubber shell layer 11 with an elastic layer 12, and the elastic layer 12 is covered with a surface layer 13, the The periphery of the surface layer 13 is folded back to the lower side of the rubber shell layer 11 and fixed with glue or / and nails. The bottom of the rubber shell layer 11 of the seat cushion body 10 is provided with a plurality of first hot-melt lines 111 protruding from the bottom. The top of the shell layer 20 is protrudingly provided with a plurali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com