Chemical coating emulsifying machine

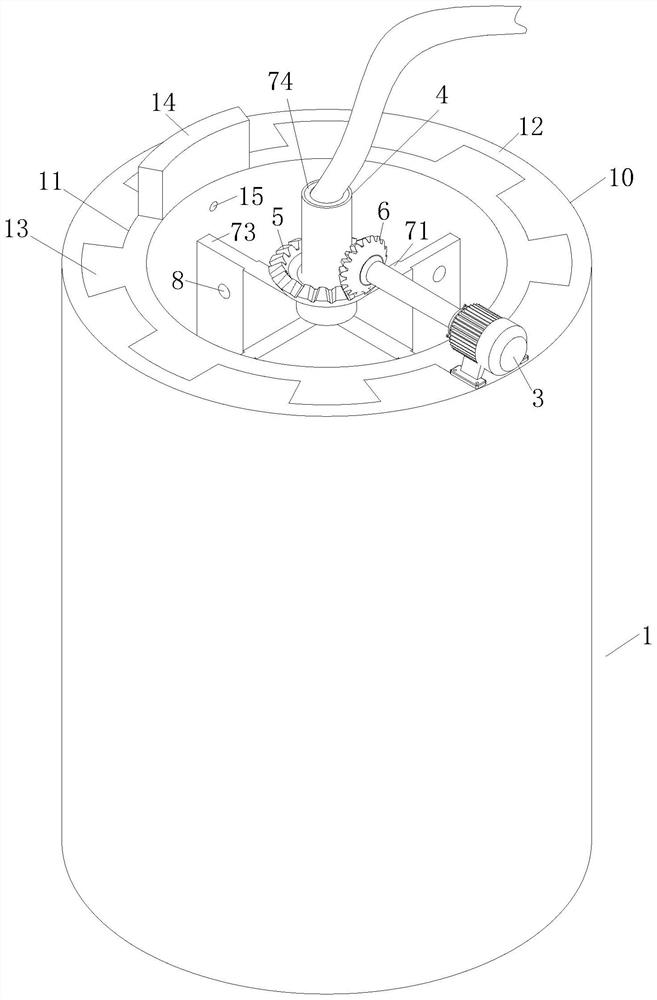

A technology for emulsifying machines and coatings, applied to mixers, mixer accessories, chemical instruments and methods, etc., can solve problems such as hanging on walls, insufficient cleaning range of cleaning boards, and affecting the working efficiency of emulsifying machines, so as to improve cleaning speed and reduce Time and difficulty, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

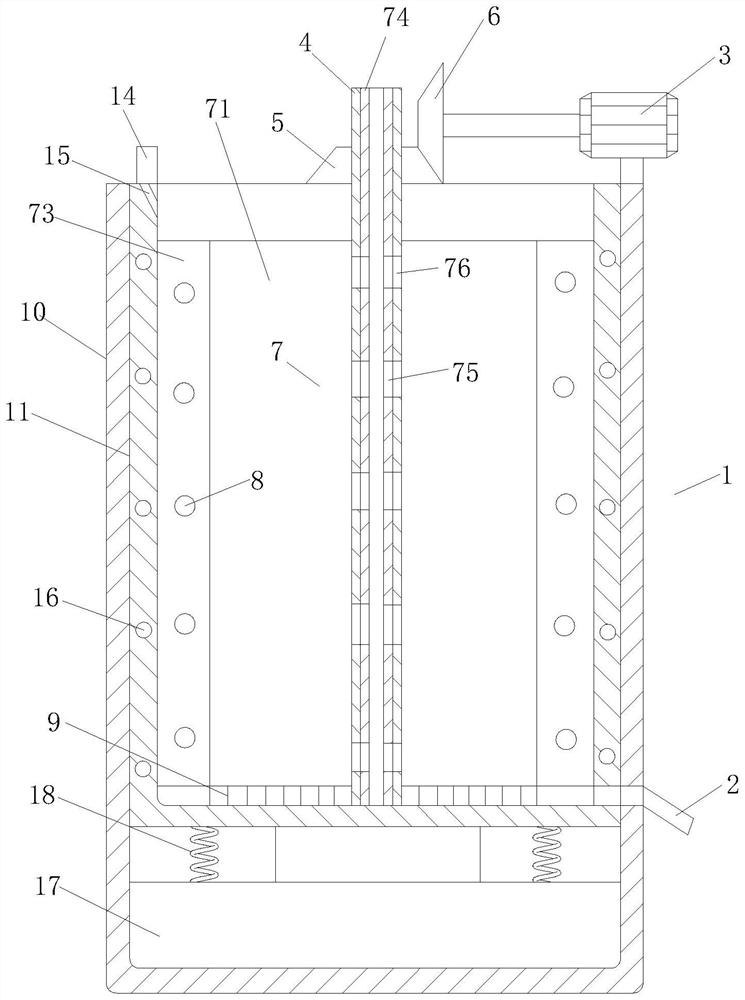

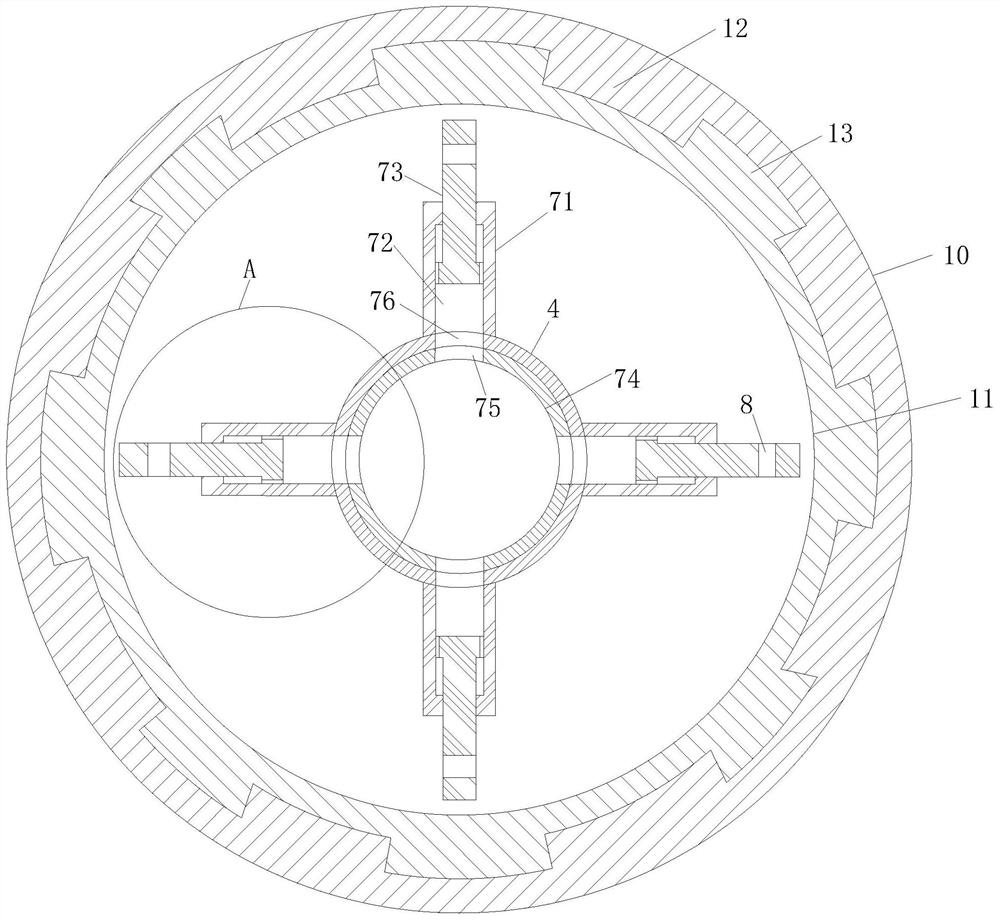

[0059]As a specific embodiment of the present invention, the scraper 73 is made of silica gel;

[0060] Because the scraper 73 is made of silica gel, when the emulsifier is working or cleaning, the chemical paint is not easy to stick to the scraper 73, which makes the cleaning of the emulsifier more convenient, improves the cleaning speed of the emulsifier, and reduces manual cleaning. Time and difficulty, thus improving the working efficiency of the emulsifying machine.

[0061] As a specific embodiment of the present invention, micropores 8 are opened on the scraper 73;

[0062] Because micropores 8 are provided on the scraper 73, when the chemical coating is stirred, a part of the chemical coating flows out through the micropores 8, which reduces the resistance when the baffle 71 and the scraper 73 stir, thereby improving the emulsification of the emulsifier. Efficiency, thereby improving the practicability of the emulsifier.

[0063] As a specific embodiment of the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com