New energy charging pile capable of quickly carrying out fire fighting and extinguishment

A new energy and charging pile technology, applied in charging stations, electric vehicle charging technology, electric vehicles, etc., can solve the problems of less fire fighting and low operating efficiency, and achieve the effects of preventing excessive temperature, improving efficiency, and convenient heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

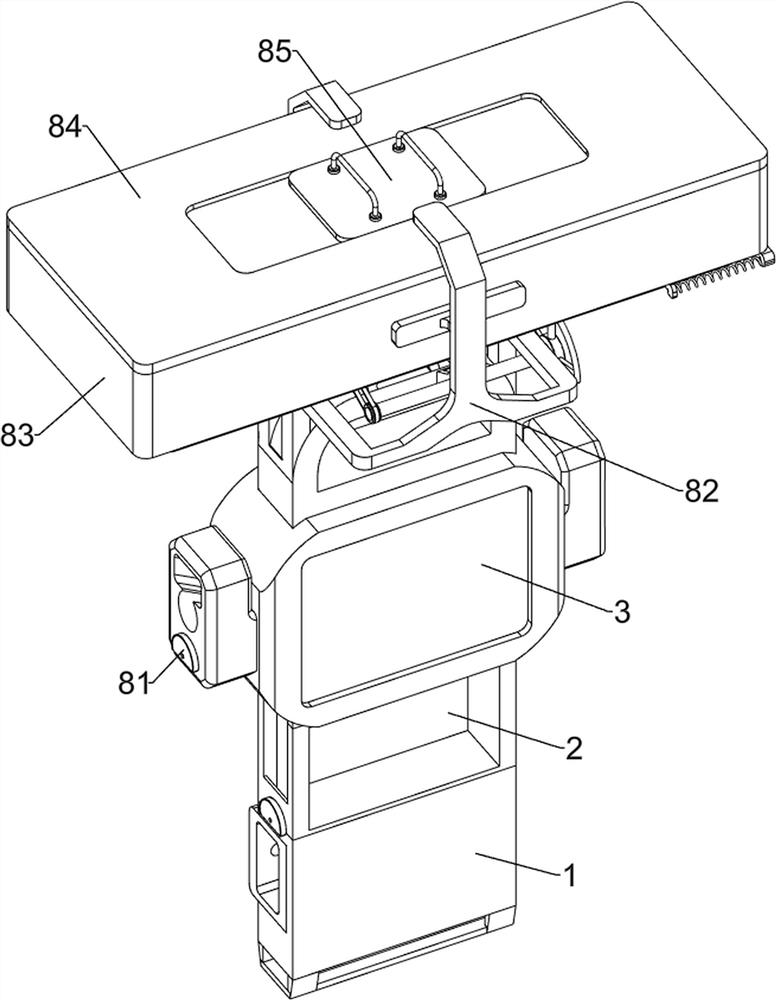

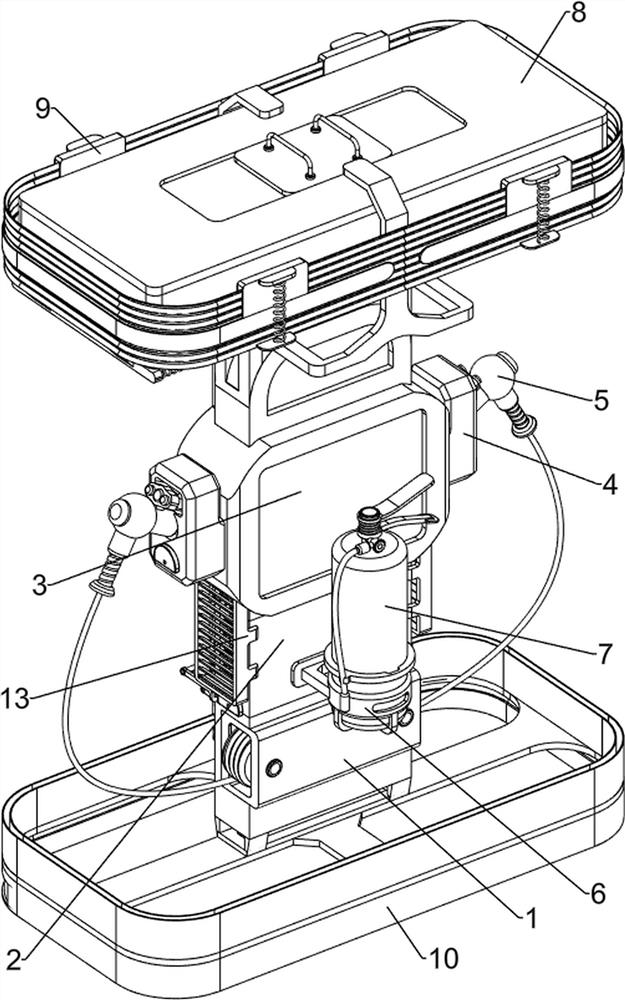

[0042] A new energy charging pile that can quickly carry out fire fighting, such as Figure 1-18 As shown, it includes an underframe 1, a first connecting plate 2, a first fixing plate 3, a placement block 4, a charging gun 5, a first fixing frame 6, a fire extinguisher 7, a feeding mechanism 8 and a covering mechanism 9. The underframe 1 The upper part is fixedly connected with the first connecting plate 2 by screws, the first connecting plate 2 is fixedly connected with the first fixing plate 3 by bolts, the left and right sides of the first fixing plate 3 are all equipped with placing blocks 4, two placing blocks 4 are snap-connected with a charging gun 5, the rear side of the first connecting plate 2 is fixedly connected with a first fixing frame 6 by bolts, a fire extinguisher 7 is placed on the first fixing frame 6, and the top of the first fixing plate 3 is connected by a screw A blanking mechanism 8 is fixedly connected, and the outer side of the blanking mechanism 8 i...

Embodiment 2

[0047] On the basis of Example 1, such as figure 1 , figure 2 and Figure 13 As shown, it also includes a receiving mechanism 10, and the receiving mechanism 10 includes a fifth fixed plate 101, a charging frame 102 and a first handle 103, and the bottom of the second connecting frame 98 is welded with the fifth fixed plate 101, and the fifth fixed plate 101 is welded. The bottom of the fixed plate 101 is equipped with an anti-slip pad, which has a certain anti-skid effect. The fifth fixed plate 101 is slidably connected with a charging frame 102. The charging frame 102 is used to collect the residual dry powder of fire extinguishing. The charging frame 102 is welded and connected. There are 103 in command.

[0048] After the fire of the new energy charging pile is extinguished, the remaining fire extinguishing dry powder falls on the fifth fixed plate 101, and the fire extinguishing dry powder on the fifth fixed plate 101 falls into the charging frame 102, so that the fire...

Embodiment 3

[0050] On the basis of Example 2, such as figure 1 , Figure 14 , Figure 15 and Figure 16 As shown, it also includes a placement mechanism 11, the placement mechanism 11 includes a connecting rod 111, a pull plate 112 and a second handle 113, and the left and right ends of the bottom frame 1 and the front side of the first connecting plate 2 are fixedly connected by screws. A pull plate 112 is slidably connected between the rods 111 and the two connecting rods 111 , and the pull plate 112 is engaged with the first connecting plate 2 , and a second handle 113 is welded on the pull plate 112 .

[0051] People can place the basic tools commonly used for fire extinguishing in the first connection plate 2. During the fire extinguishing process of the new energy charging pile, people can take out some basic tools commonly used for fire extinguishing in the first connection plate 2 to extinguish the fire. After finishing, people can manually put back the used basic tools for fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com