Garbage incinerator

A garbage incinerator and shell technology, which is applied in the field of incineration, can solve the problems of garbage dispersal and other problems, and achieve the effects of preventing garbage from smoldering, improving practicability, and evenly distributing garbage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

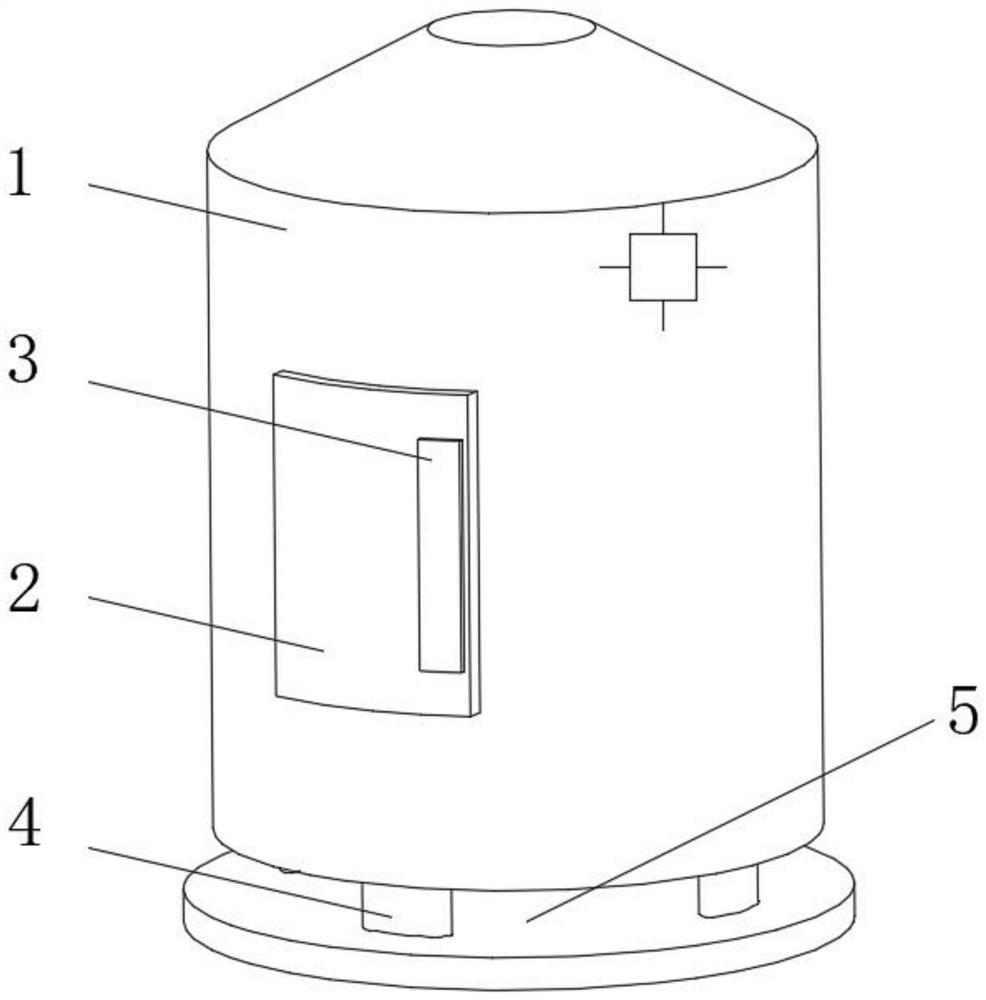

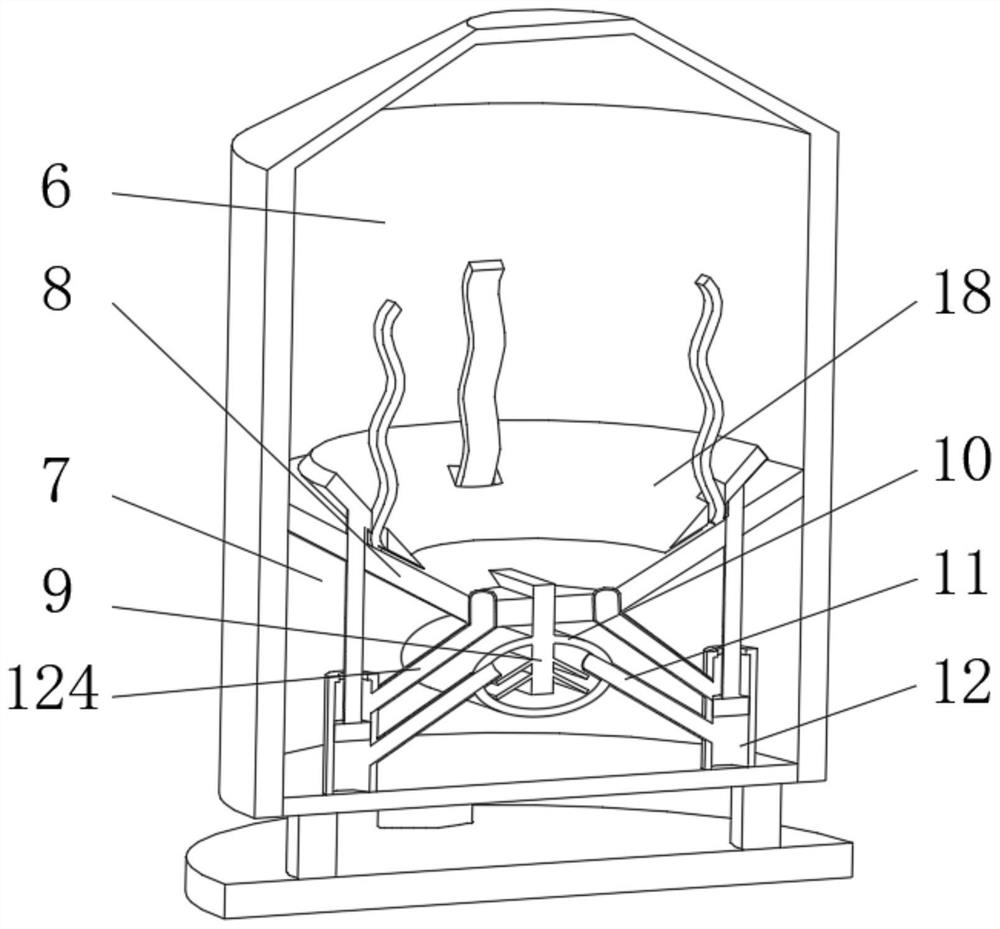

[0028] see Figure 1-4 , the present invention provides a technical solution: a garbage incinerator, comprising a shell (1), characterized in that: a feed door (2) is installed on one side of the shell (1), and the feed door (2 ) is equipped with a heat-insulating handle (3), the bottom of the housing (1) is evenly equipped with a support frame (4), and the end of the support frame (4) away from the housing (1) is fixedly connected with a base (5 ), the inside of the shell (1) is provided with an incineration chamber (6) and a control chamber (7), and the incineration chamber (6) and the control chamber (7) are separated by a conical partition (8), so One side of the tapered partition (8) is fixedly connected with a heat conduction plate (9), and the inside of the control chamber (7) is equipped with a reaction frame (10) near the position of the tapered partition (8). One side of the plate (9) extends through the tapered partition (8) to the inside of the reaction frame (10)...

Embodiment 2

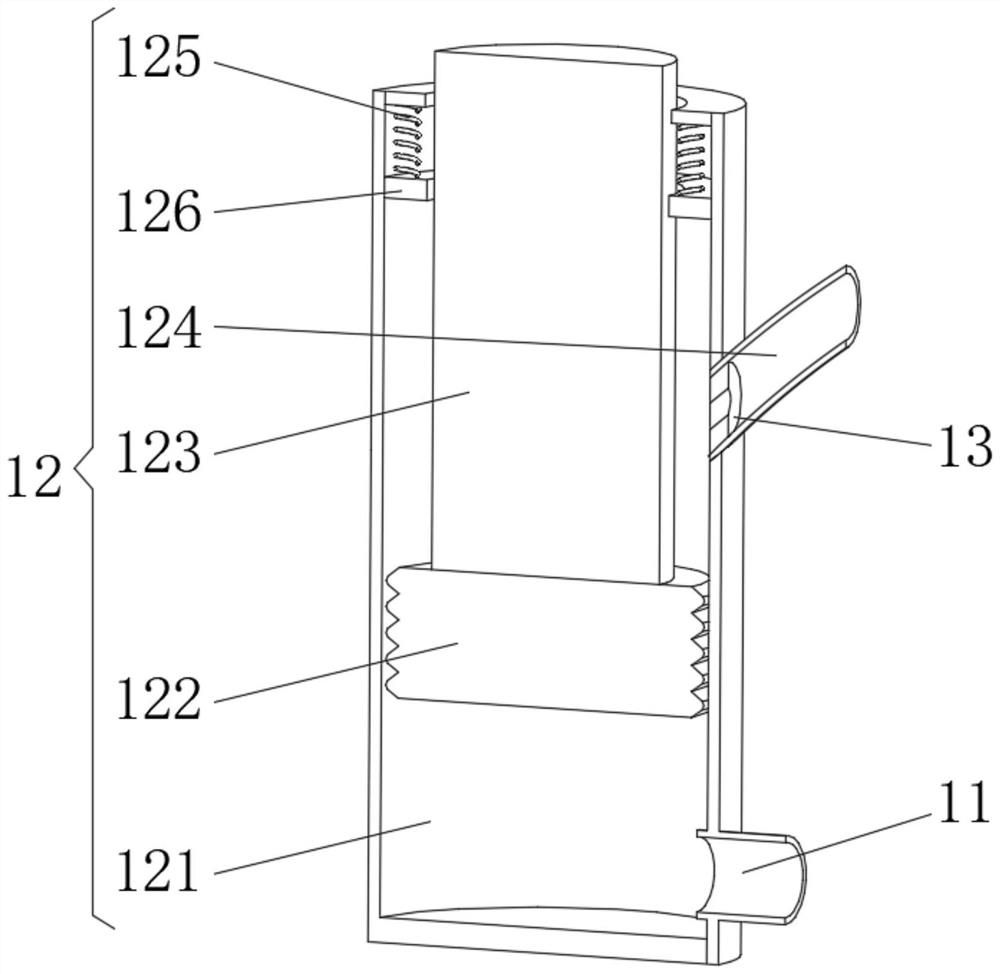

[0034] see Figure 1-5 , the present invention provides a technical solution: on the basis of Embodiment 1, a hole adjustment device (13) is installed inside the pushing device (12), and the hole adjustment device (13) includes a fixing plate (131), the The outer side of the fixed plate (131) is rotatably connected with the inner wall of the air outlet pipe (124), and one side of the fixed plate (131) is provided with an annular groove (132), and the inner wall of the annular groove (132) is fixedly connected with an extrusion Spring (133), one end of described extruding spring (133) is fixedly connected with movable fan-shaped plate (134), and the side of described movable fan-shaped plate (134) away from extruding spring (133) runs through and is connected with guide plate ( 135), the end of the guide plate (135) away from the movable fan-shaped plate (134) is fixedly connected with an air pipe (136).

[0035] The outer sides of the ventilation pipe (136) are provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com