Pre-filled syringe clamping and conveying system

A clamping conveying and conveying system technology, applied in the direction of conveyors, mechanical conveyors, conveyor objects, etc., can solve the problem of conveying speed, accuracy error function expansion equipment maintenance, conveying line accuracy, speed and automation expansion degree lagging behind, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

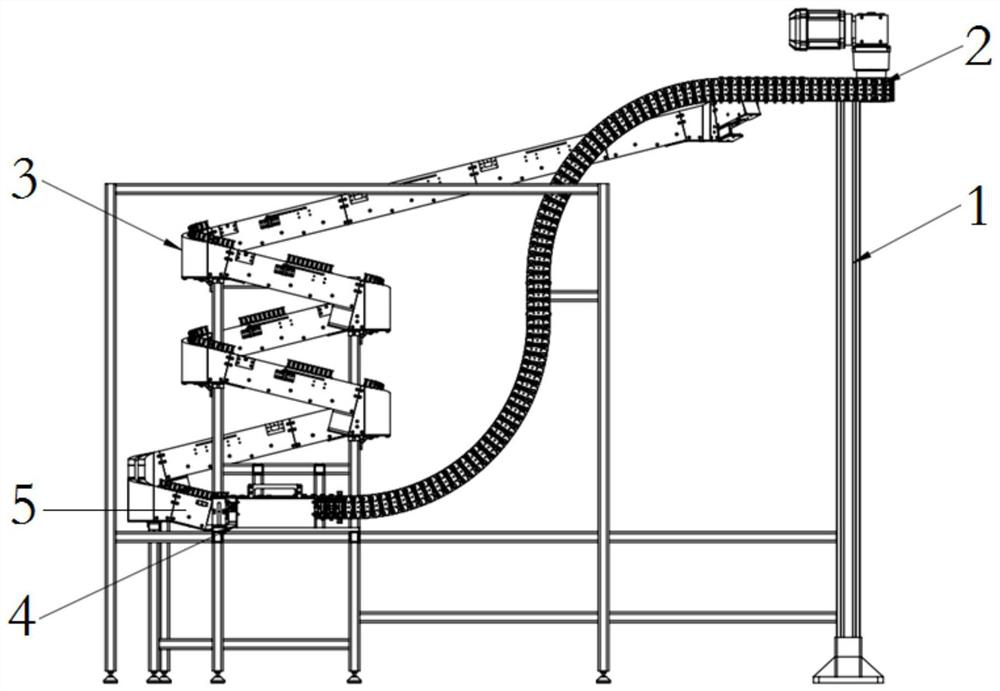

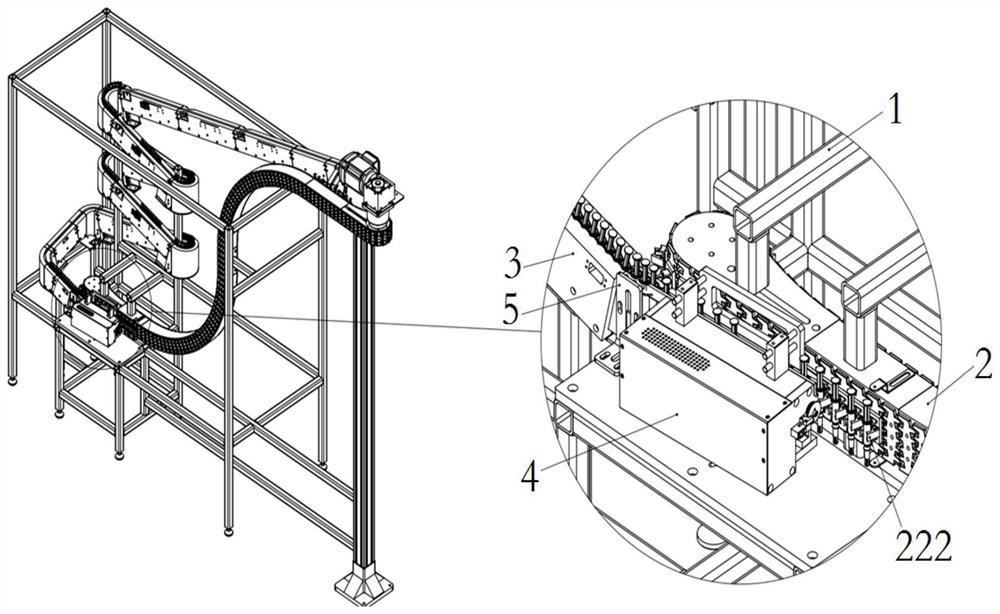

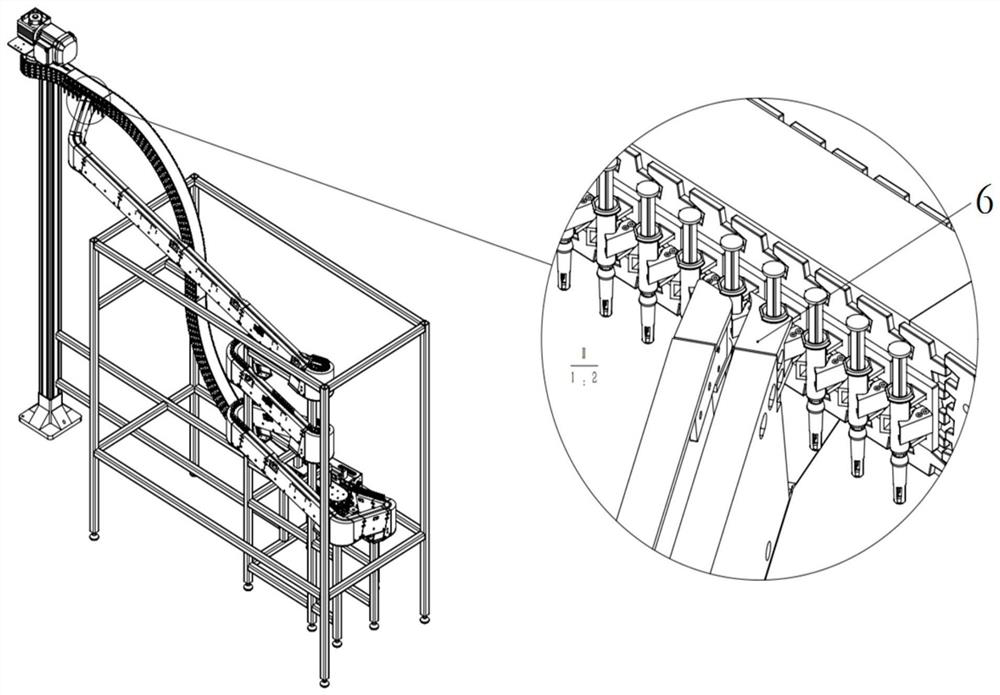

[0032] Such as Figure 1-3 As shown, a prefilled syringe clamping and conveying system includes a system frame 1 and a flexible clamping and conveying system 2 installed on the system frame, a slideway type non-powered conveying system 3, and a synchronously pushing and paralleling mechanism 4; Wherein, the front end of the slideway type non-powered conveying system 3 is docked with the outlet of the flexible clamping conveying system 2, and the tail end is docked with the synchronous pushing and paralleling mechanism 4; the synchronous pushing and paralleling mechanism 4 is located on the rack table for The pre-filled syringe is transported to the flexible clamping delivery line of the flexible clamping delivery sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com