Connecting beam and underwater tractor

A tractor and connecting beam technology, applied in the field of wave gliders, can solve the problems of reducing the load capacity of the surface mother ship, the overall weight of the tractor, and the stress concentration at the connection, so as to improve the forward performance, increase the service life, and reduce the stress. concentrated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

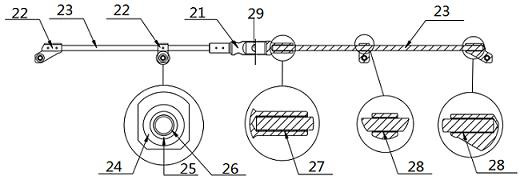

[0030] This embodiment provides a connecting beam 2, such as Figure 1 and Figure 3 As shown, it includes two connecting rods 23, a plurality of connecting seats 22 and a connector 21. The two connecting rods 23 are coaxial, and the two connecting rods 23 are respectively arranged at both ends of the length direction of the connector 21. The connector 21 and the two connecting rods 23 can be rotatably connected around the axis of the connecting rod 23. The connector 21 is provided with a rotating shaft 29 parallel to the horizontal plane, and a rotating shaft 29 is arranged on the front and rear sides of the connector 21, The two rotating shafts 29 are arranged coaxially, the axis of the rotating shaft 29 is perpendicular to the axis of the connecting rod 23, and the axis of the rotating shaft 29 is in the same plane with the axis of the connecting rod 23, the bottom end of the armored cable can be rotatably connected to the rotating shaft 29 around the axis of the rotating shaft 2...

Embodiment 2

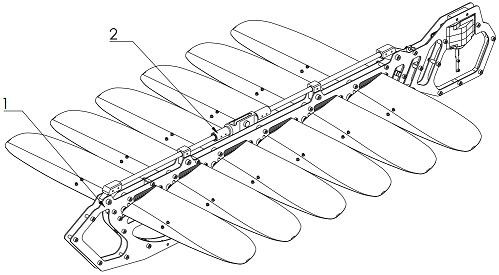

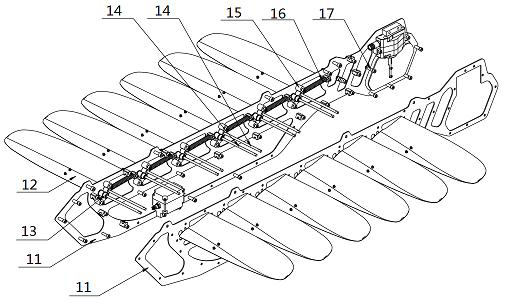

[0039] The embodiment provides an underwater tractor, such as Figure 1 and Figure 2 As shown in the figure, it includes the connecting beam 2, the tractor body and the armored cable described in embodiment 1. A plurality of connecting seats 22 are arranged on the top of the underwater tractor body 1, the bottom end of the armored cable can be rotatably connected to the rotating shaft 29 around the axis of the rotating shaft 29, and the top end of the armored cable is connected with the surface mother ship.

[0040] The connecting beam 2 in the underwater tractor provided by this embodiment is connected with the underwater tractor body 1 through a plurality of connecting seats 22, which reduces the stress concentration, and the setting form of the connector 21 realizes the integration of two degrees of freedom, centralizes the pitching and rolling joints in one place, realizes the down regulation of the pitching joint, and reduces the moment of the pitching force arm, the hydrodyna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com