Traction vertical seawater corrosion prevention fiberboard laminating equipment for port

A seawater corrosion and bonding equipment technology, applied in the field of seaports, can solve the problems of falling and hurting people, difficulty in attaching rubber materials, and weak bonding of basalt fiberboards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

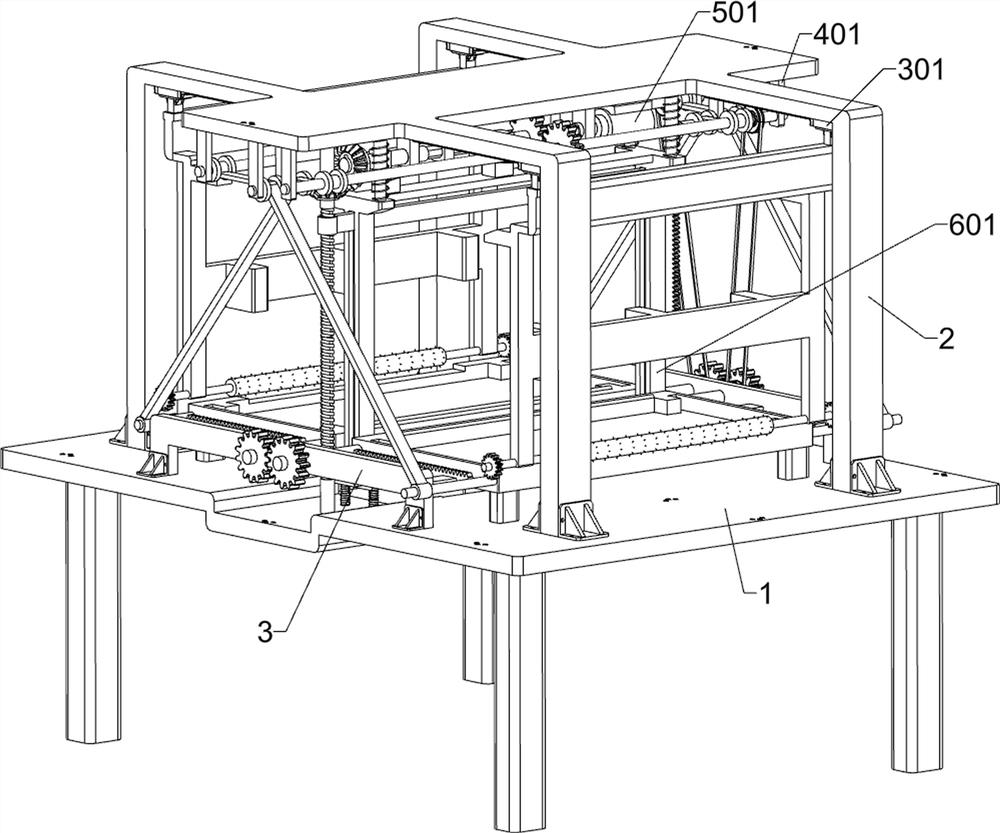

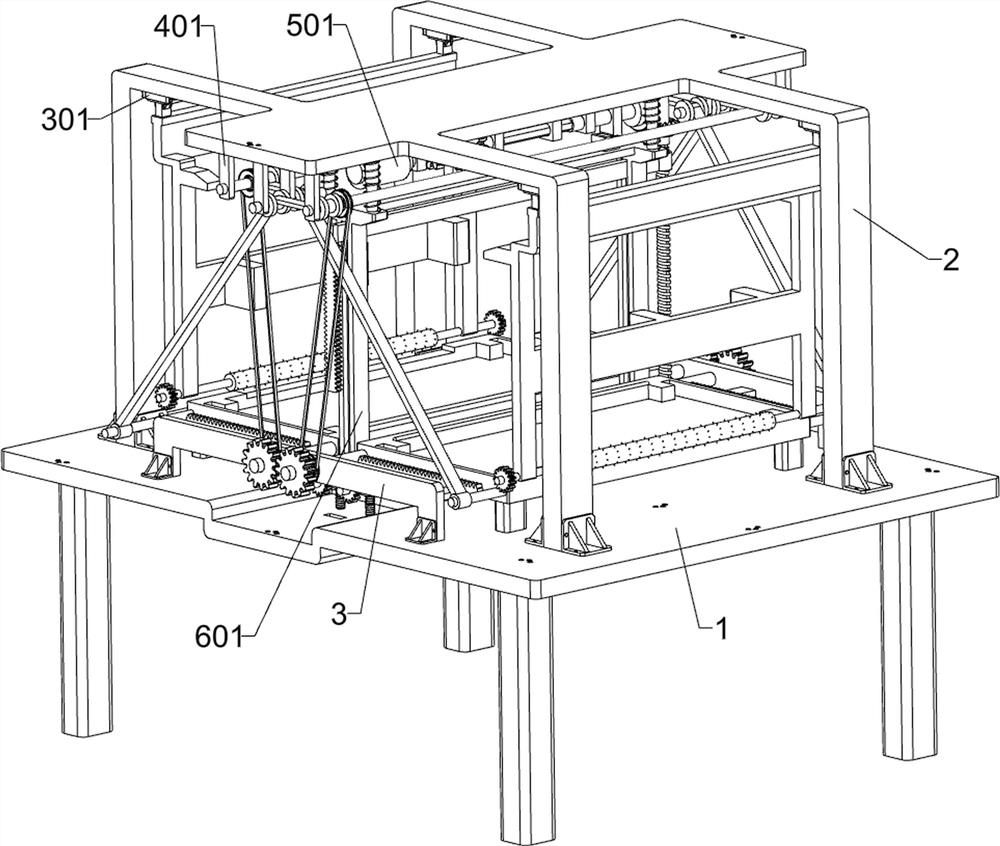

[0034] A kind of pulling vertical port seawater corrosion-proof fiberboard laminating equipment, according to Figure 1-12 As shown, it includes a base frame 1, a support frame 2, a gear frame 3, a fiber barb unit, a pulling unit and a power unit; the upper surface of the base frame 1 is connected with a support frame 2; Each rear part is connected with a gear frame 3; the inside of the support frame 2 is connected with a fiber barb unit; the upper surface of the bottom frame 1 is connected with a pulling unit, the pulling unit is connected with the support frame 2, and the pulling unit is connected with the gear frame 3 Connection; the top of the support frame 2 is connected with a power unit, and the power unit is connected with the pulling unit.

[0035] When working, place the bottom frame 1 horizontally so that the device is on a level ground, and then connect the power supply. The operator puts the two basalt fiber boards that need to be fitted and compacted into the pul...

Embodiment 2

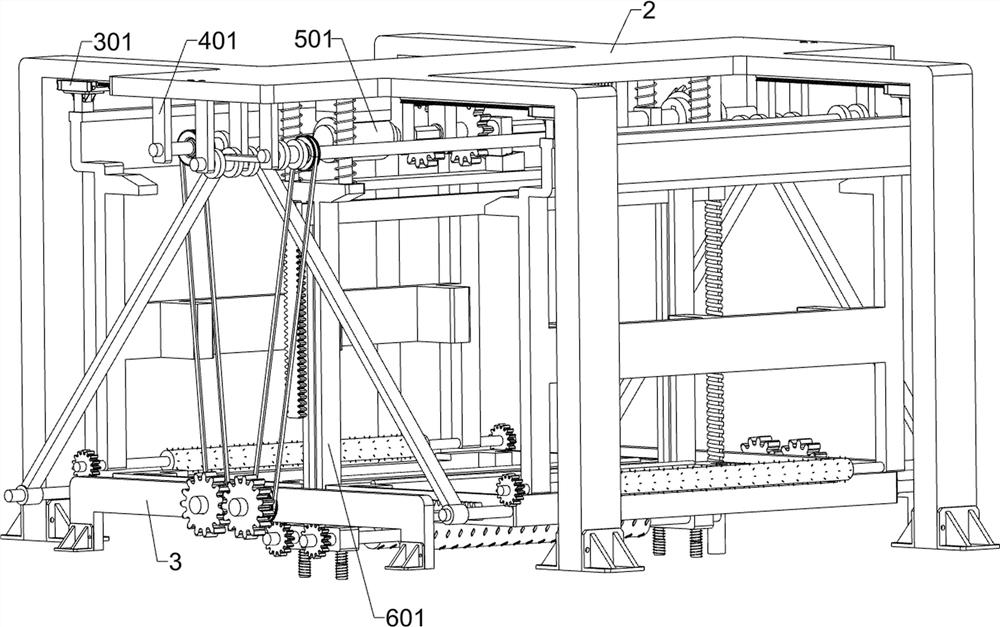

[0037] On the basis of Example 1, according to figure 1 and Figure 4-12 As shown, the fiber barb unit includes an electric sliding block 301, an electric sliding rail 302, a moving plate 303, a wedge block 304, a horizontal plate 305, a push block 306, a first transmission shaft 307, a tie roller 308, and a first flat gear 309 and the second spur gear 3010; two electric sliding rails 302 are fixed symmetrically on the top left inner wall and the top right inner wall of the support frame 2; the two electric sliding rails 302 on the left and the two electric sliding Each of the rails 302 is slidably connected with an electric sliding block 301; the two electric sliding blocks 301 on the left and the two electric sliding blocks 301 on the right are each bolted with a moving plate 303; the opposite sides of the two moving plates 303 A wedge-shaped block 304 is welded on the front upper side and the rear upper side of the two moving plates 303; a transverse plate 305 is welded in...

Embodiment 3

[0046] On the basis of Example 2, according to figure 1 and Figure 13-14 As shown in the figure, it also includes a discharging unit. A discharging unit is connected between the bottom frame 1 and the supporting frame 2. The discharging unit includes a fixed frame 601, a third spring telescopic rod 602, an eighth transmission shaft 603, a rolling roller 604, seventh spur gear 605, fourth spring telescopic rod 606, first extrusion block 607, second extrusion block 608, moving rod 609, bidirectional rack 6010, screw 6011 and second bevel gear 6012; support frame The top of 2 is arranged in a matrix with four third spring telescopic rods 602; the telescopic parts of the four third spring telescopic rods 602 are fixed with a fixed frame 601; the middle part of the horizontal rod of the fixed frame 601 is fixed with a first extrusion block 607; a second extrusion block 608 is fixedly connected to the rear of the cross bar of the fixed frame 601; the lower part of the fixed frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com