Thin seam coal mining machine

A technology for shearer and thin coal seam, which is applied to slitting machinery, cutting machinery, earth-moving drilling, etc., can solve the problems of large influence of force on the whole machine, small mining height of rear drum, and narrow mining height of shearer. , to achieve the effect of improving overall reliability, compact overall space, and reducing continuous power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

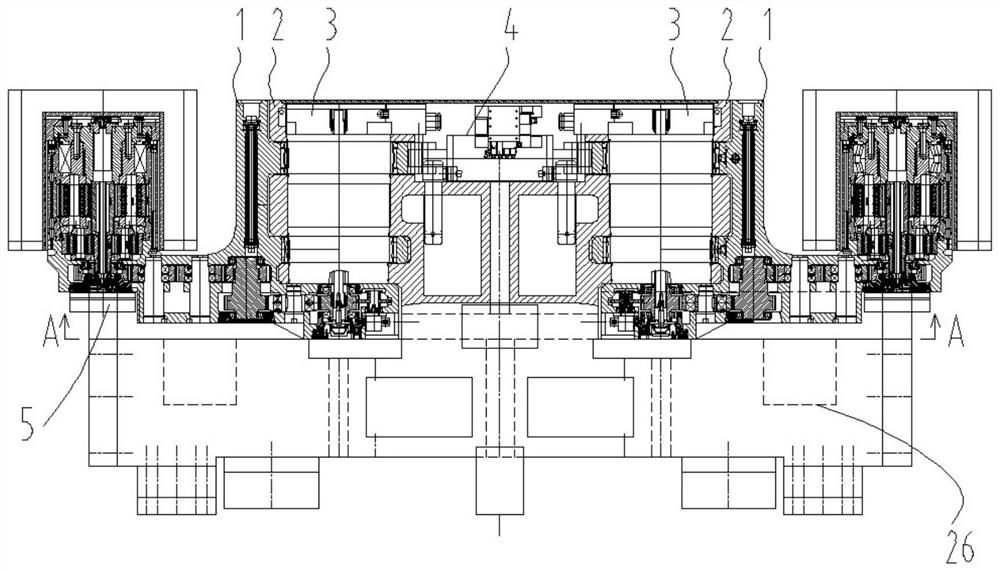

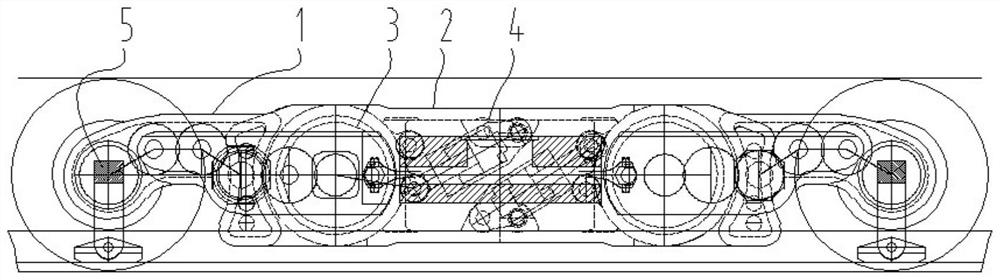

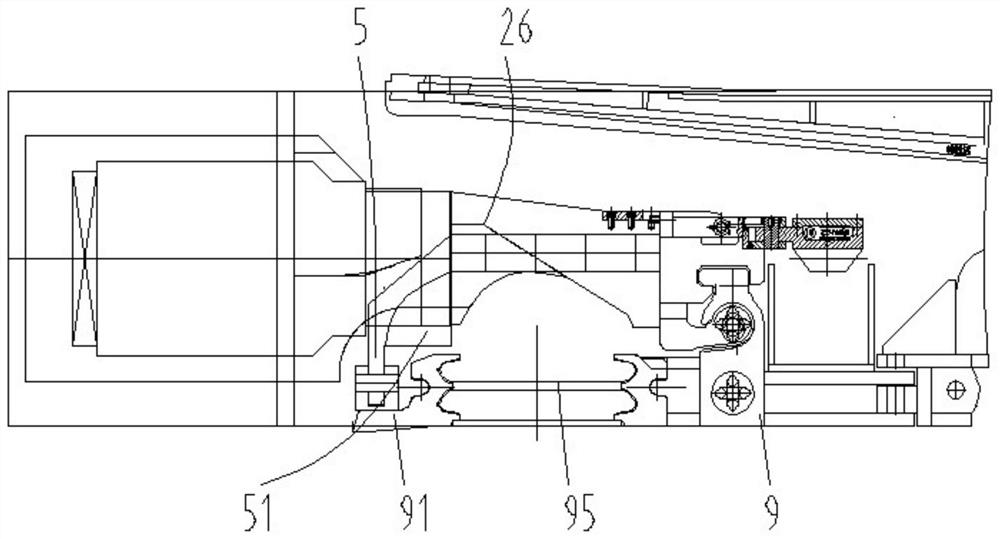

[0039] The invention discloses a thin coal seam shearer, such as Figure 1-6As shown, it includes a main body housing 2 and two swing arm housings 11 respectively hinged at the left and right ends of the front part of the main body housing. Each swing arm housing and the main body housing are separated by a The motor 3 is used as a hinge pin, and the cutting motor is fixed relative to the main body housing and swings relative to the swing arm housing. By using the cutting motor as a pin shaft, the left and right lengths of the main body casing are shortened, which is equivalent to shortening the left and right lengths of the suspension body section of the shearer, and the structure of the cutting mechanism is simplified. Due to this special articulated structure, each swing arm housing is driven by a cutting motor. On a double-drum shearer, the overall cutting power is greater than that of a single cutting motor, and the single cutting motor can be reduced during two-way minin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com