Wave wall and construction method thereof

A technology of wave break wall and accommodating tank, which is applied in dikes, marine engineering, water conservancy projects, etc., can solve the problems of large area of wave break wall, increase the construction cost of dams, etc., and achieve the effect of good wind and wave protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0063] The construction method of the anti-wave wall includes the following steps:

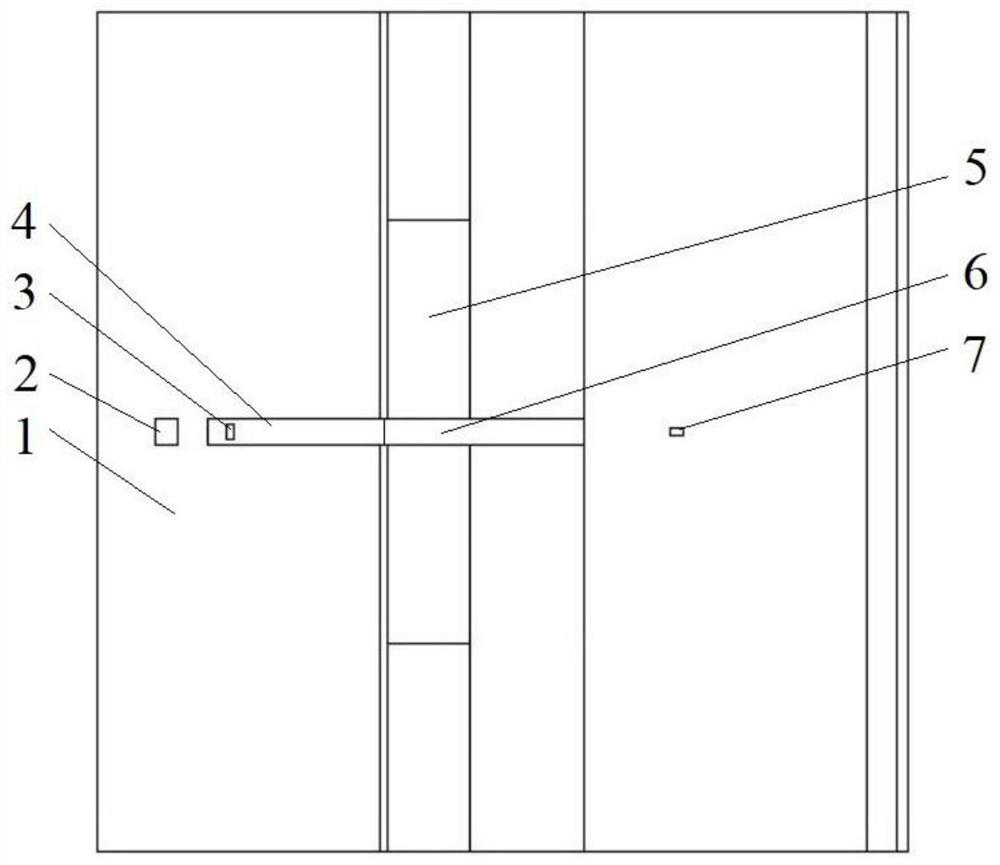

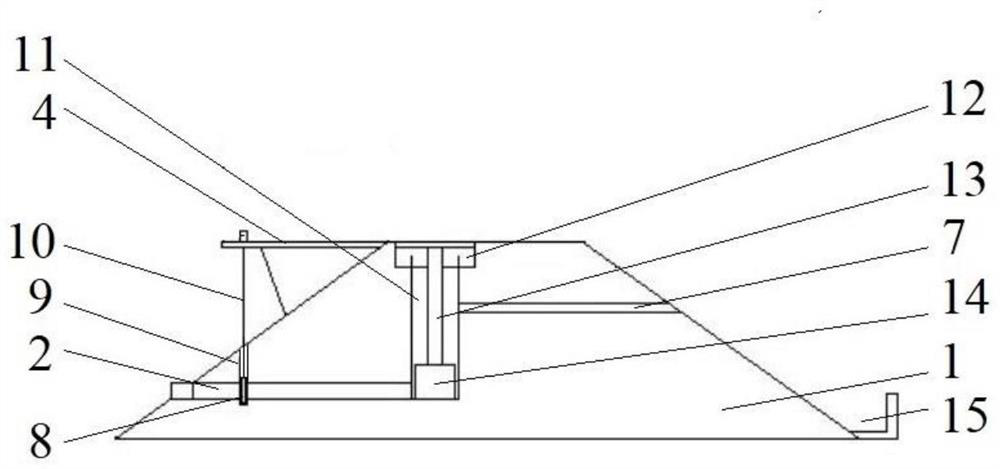

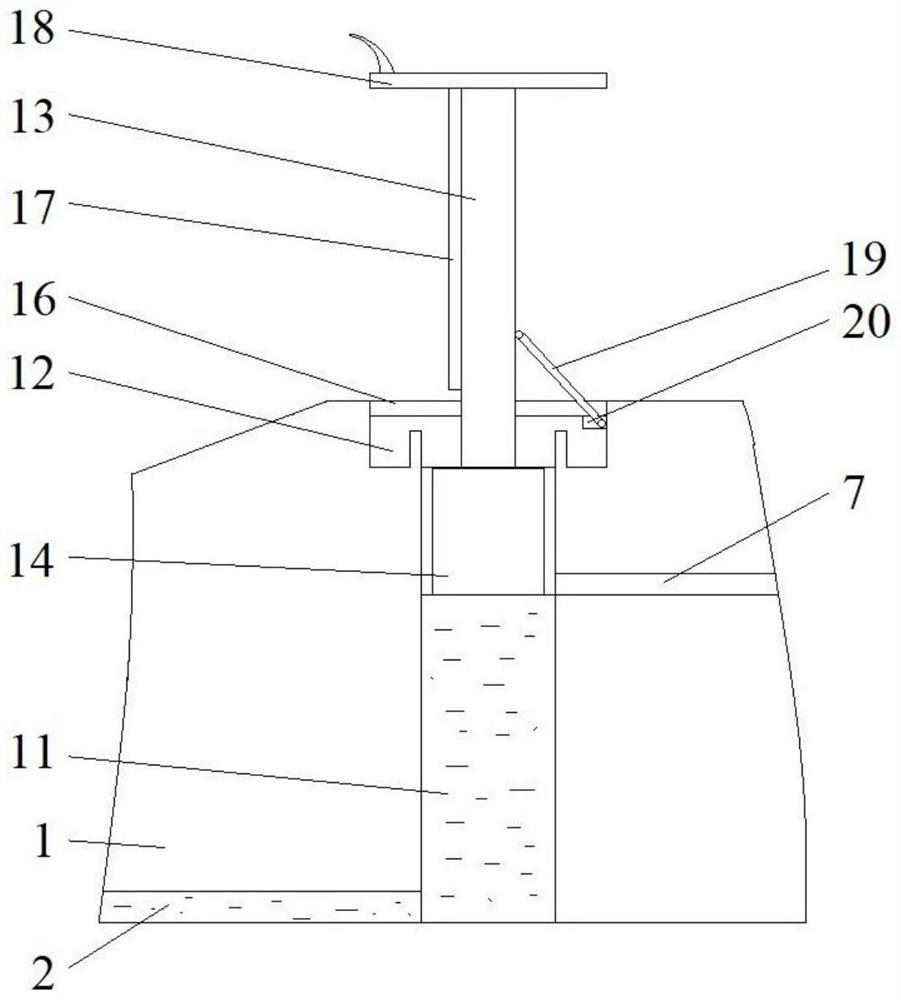

[0064] Step 1: Construct the embankment, and reserve the outflow channel, the moving trough, the containment trough, the support trough, the limit hole, the overflow channel, and prepare the prefabricated anti-wave wall and the limit bump;

[0065] Step 2: Build a support platform and place access plates, blockage blocks, moving rods, and filters;

[0066] Step 3: Place the prepared prefabricated wave-proof wall in the containment groove, and then turn the moving lever to move the block down to block the flowing water channel, fill the water in the containment tank, make the prefabricated anti-wave wall float up and keep it upright, and then install the limit bump and the limit rod in turn;

[0067] Step 4: Rotate the moving lever to move the block up to open the flow channel, release the water in the storage tank clean, and make the prefabricated anti-wave wall fall and collect it in the storage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com