Track beam hoisting equipment suitable for high-speed magnetic levitation

A lifting equipment, maglev track technology, applied in cranes, load hanging components, transportation and packaging, etc., can solve the problems of high installation accuracy, heavy beam body, limited working space, etc., to ensure reliability and accuracy , improve stability and reliability, and ensure the effect of efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

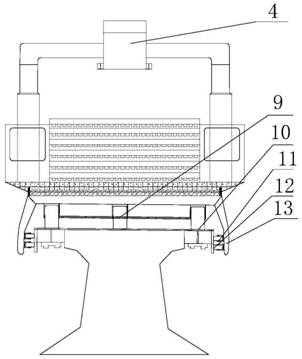

[0040] See Figures 1 to 5 , preferred embodiments of the present invention suitable for high-speed maglev rail beam lifting apparatus comprising a car body, the bottom of the car body is provided with a walking mechanism, the top is provided with a support structure, and the support structure is provided with a hoisting main beam 4, and the end of the hoisting main girder 4 is connected by a plurality of sling ropes 3 is provided with an electromagnetic lifting fixture 1. Then, through the walking mechanism to achieve the rail beam lifting equipment on the T-beam, and then through the electromagnetic lifting fixture 1 pair of rail beam top surface adsorption, you can complete the hoisting of the high-speed maglev rail beam.

[0041] Specifically, the car body in an embodiment is preferred, such as Figure 2 As shown in, it comprises a support base plate, the lower support plate is provided with a walking mechanism, preferably the walking mechanism in the embodiment comprises two w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com