Transcritical carbon dioxide air conditioning system for electric bus

An air-conditioning system, carbon dioxide technology, applied in component optimization, air handling equipment, heating/cooling equipment, etc., can solve problems such as high requirements, failure to meet environmental protection requirements, and reduced cruising range, and meet the requirements of system overheating. requirements, overcome the low heating efficiency, and increase the effect of suction superheat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0020] It should be pointed out that the following detailed description is exemplary and is intended to provide further explanation to the present application. Unless otherwise specified, all technical and scientific terms used herein have the same technical meaning as commonly understood by one of ordinary skill in the art to which this application belongs.

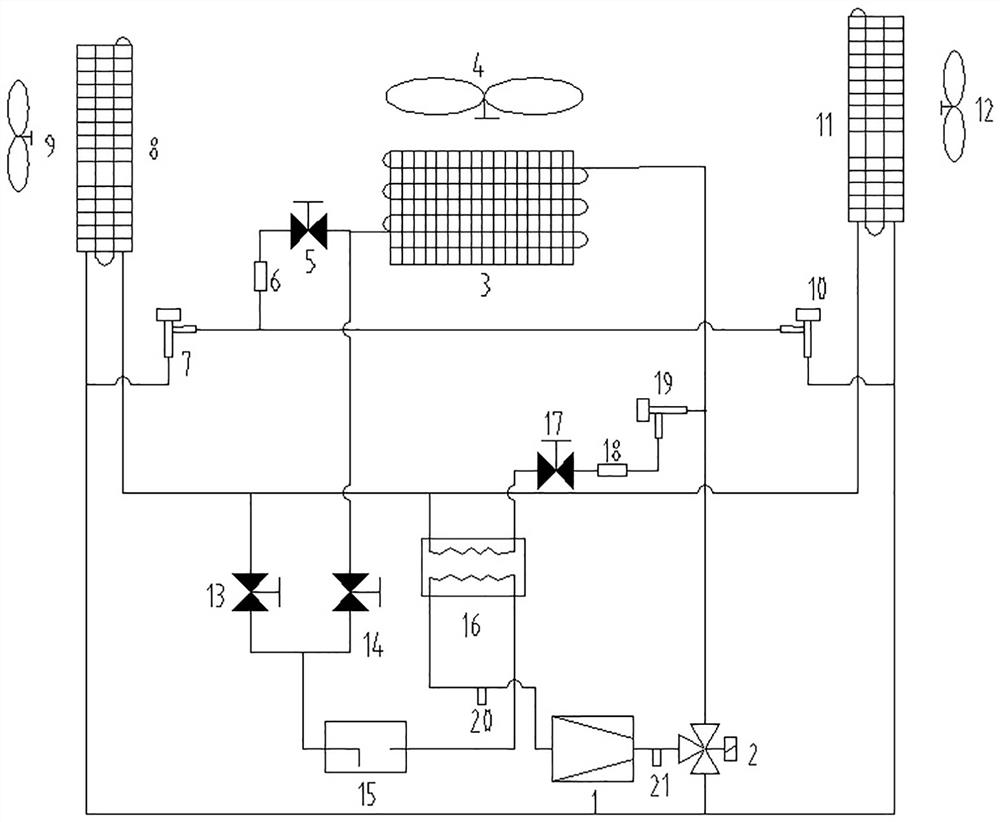

[0021] A transcritical carbon dioxide air-conditioning system for an electric bus, the system includes a compressor 1, a three-way valve 2, an external heat exchanger 3, a first dry filter 6, a second dry filter 18, and an internal heat exchanger , gas-liquid separator 15, regenerator 16, the outlet of compressor 1 is connected to the first port of three-way valve 2, the second port of three-way valve 2 is connected to the inlet of external heat exchanger 3, and the port of thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com