Special instrument for removing plaster mold after orthopedic treatment

A post-treatment, plaster cast technology, applied in the field of orthopedic equipment, can solve the problems of reducing the efficiency of plaster removal, increasing the operation intensity of medical staff, etc., to achieve the effect of improving efficiency and reducing operation intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

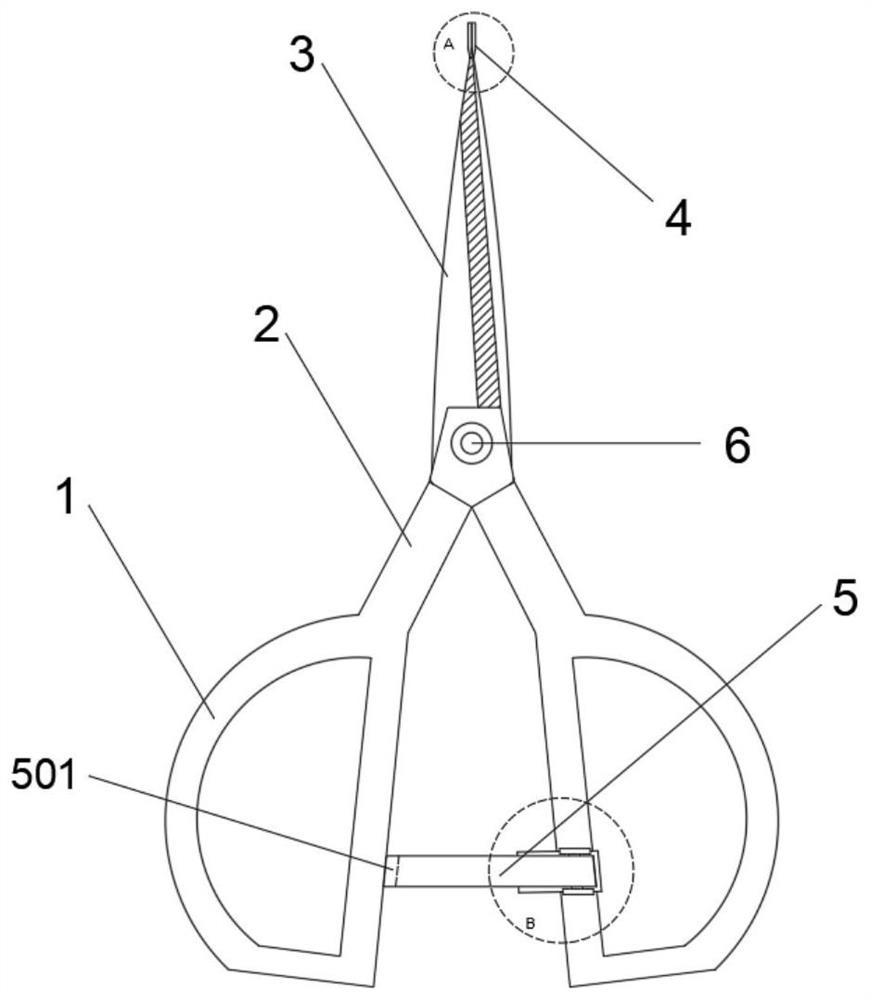

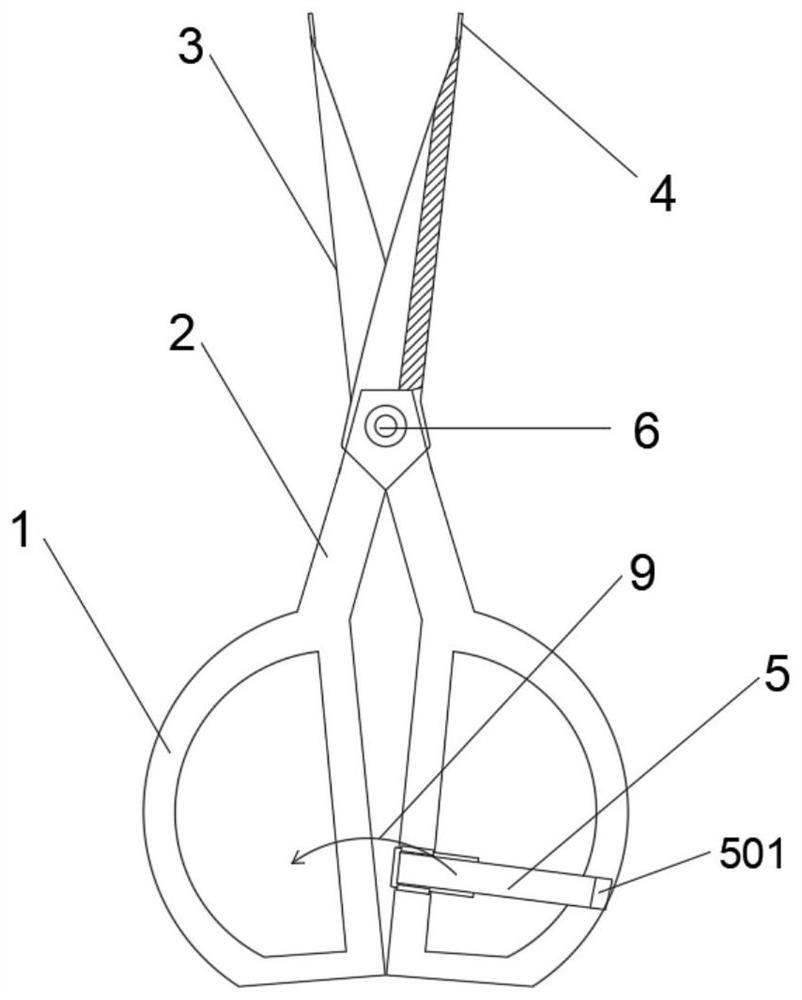

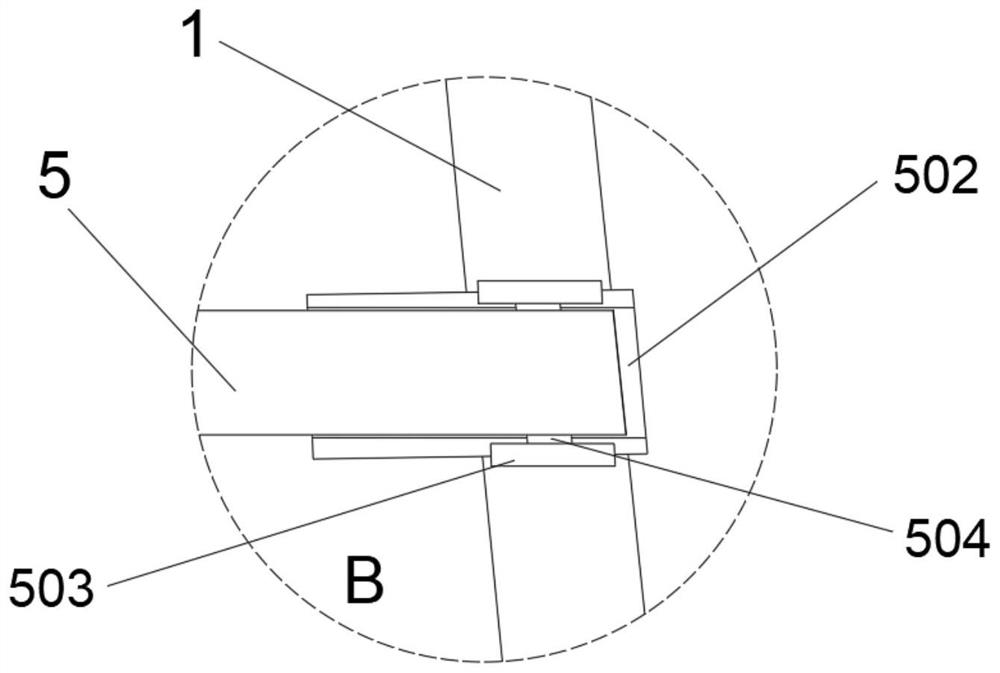

[0037] A special instrument for removing a plaster cast after orthopedic treatment, comprising a first scissors body and a second scissors body hinged to each other, each of the first scissors body and the second scissors body includes a blade part 3, a handle part 2 and a handle part 1 , the handles 2 of the first scissors body and the second scissors body are hinged by the pin 6, so that the handle 1 drives the first scissors body and the second scissors body to rotate crosswise around the pin 6.

[0038] When the handles 1 of the first scissors body and the second scissors body are in contact, the blades 3 of the two are in a crossing state, that is, the two backs of the blades are located between the two cutting edges, and the cutting edges of the two are in a state away from each other. When the handles 1 of the first scissors body and the second scissors body are in contact, the spreading function is realized; when the handles 1 of the first scissors body and the second s...

Embodiment 2

[0048] The main difference from Embodiment 1 is that the limit adjustment mechanism may include a first limit rod and a second limit rod that are correspondingly rotated on the first scissor body and the second scissor body handle 1, and the second limit rod The first limiting rod and the second limiting rod are located on the same side, and the first limiting rod and the second limiting rod are rotatably arranged on the handle part 1 , and the specific rotation setting method can refer to Embodiment 1. When the first stop bar and the second stop bar rotate until their ends touch, the blades 3 of the first scissors body and the second scissors body are in a superimposed state, and the two cutting edges are located between the two backs .

Embodiment 3

[0050] Such as Figure 9-10 As shown, the main difference from Embodiments 1 and 2 is that the limit adjustment mechanism is different, and the limit adjustment mechanism may include a buckling plate 7 and a buckling slot 8 for buckling. The inner side of the handle part 1 of the first scissors body is fixed with a limited rotating shaft through a bearing seat, and one end of the fastening plate 7 is rotationally connected with the rotating shaft. The limit shaft can use a one-word damping shaft. In addition, according to actual needs, the fastening plate 7 only needs to be rotated by 90°, so the one-word damping shaft can be a one-word damping shaft with a 90° limit. The rotation angle range of the shaft within 90°. The fastening plate 7 has an L-shaped structure, and the fastening groove 8 is correspondingly opened on the handle portion 1 of the first scissors body, on the same side as the fastening plate 7 . The short side of the fastening plate 7 is used for inserting in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com