Device for measuring parallelism of micro electrode plate group

A technology of micro-electrodes and parallelism, which is applied in the direction of measuring devices, electric devices, and fluid devices, etc., can solve the problems of inability to detect the parallel position of micro-electrode plate groups, and achieve the effect of ensuring the detection environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

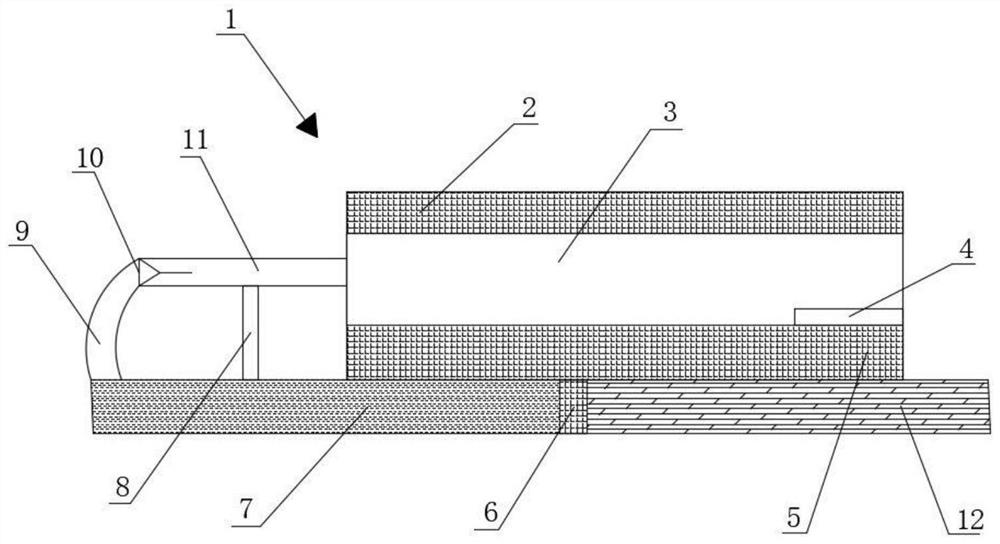

[0029] A device for measuring the parallelism of a micro-electrode plate group, comprising a device body 1, the device body 1 includes a functional base, and a test cavity 3 for parallelism detection is fixedly connected to the functional base. The chamber 3 contains a fluid medium.

[0030] It should be noted that a test chamber 3 is provided in the device body, and the micro-electrode plate group to be tested is arranged in the test chamber 3. Preferably, the fluid medium can be air, and air is selected as the fluid medium in the parallelism measurement. On the one hand, it can ensure that the electrode plate will not be damaged during the test as much as possible; on the other hand, the air is easy to obtain and will not cause waste of resources. In detail, one side or the surrounding side of the test chamber 3 described in this application is a see-through structure, and testers can intuitively observe the state and results of the internal test through the chamber wall. S...

Embodiment 2

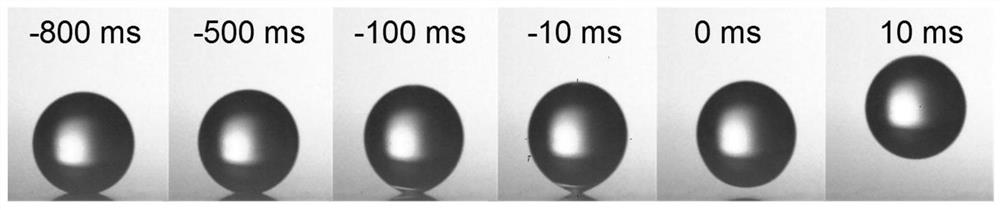

[0043] Please refer to the attached figure 2 , on the basis of Example 1, this example uses a high-speed camera to record the process of the reciprocating jump of the droplet at a rate of 60,000 frames per second, and uses image collection software to obtain a motion video, and finally calculates the speed, acceleration, and displacement through an algorithm. Analysis of parameters.

[0044] Specifically, by changing the distance between the two micro-electrode plates so that the vertical distance between the two micro-electrode plates is L=5.5mm-14.5mm, the deformation process and electric current of the droplet on the surface of the micro-electrode plates were studied. threshold.

[0045] When a droplet with a radius of 1.0mm is placed on the surface of the microelectrode plate with L=5.5mm, when the applied voltage E≥3.2KV, the droplet begins to elongate, and then has a tendency to leave the microelectrode plate, such as figure 2 shown. In the present embodiment, the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com