Mechanical arm for hydrogen filling of hydrogen energy automobile

A technology of mechanical arms and automobiles, applied in mechanical equipment, motor vehicles, road vehicles, etc., can solve the problems of reducing the safety and reliability of hydrogenation process, increasing labor cost and labor intensity, and low degree of automation, so as to improve the sealing effect and Increased service life, deformability, and reduced workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

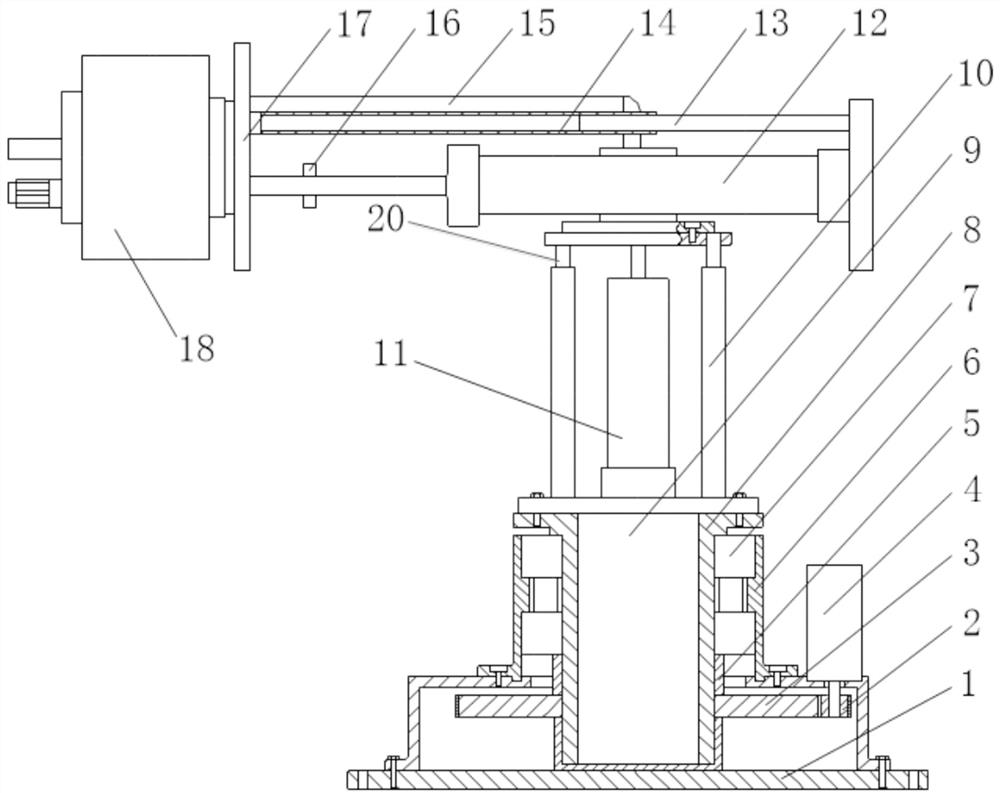

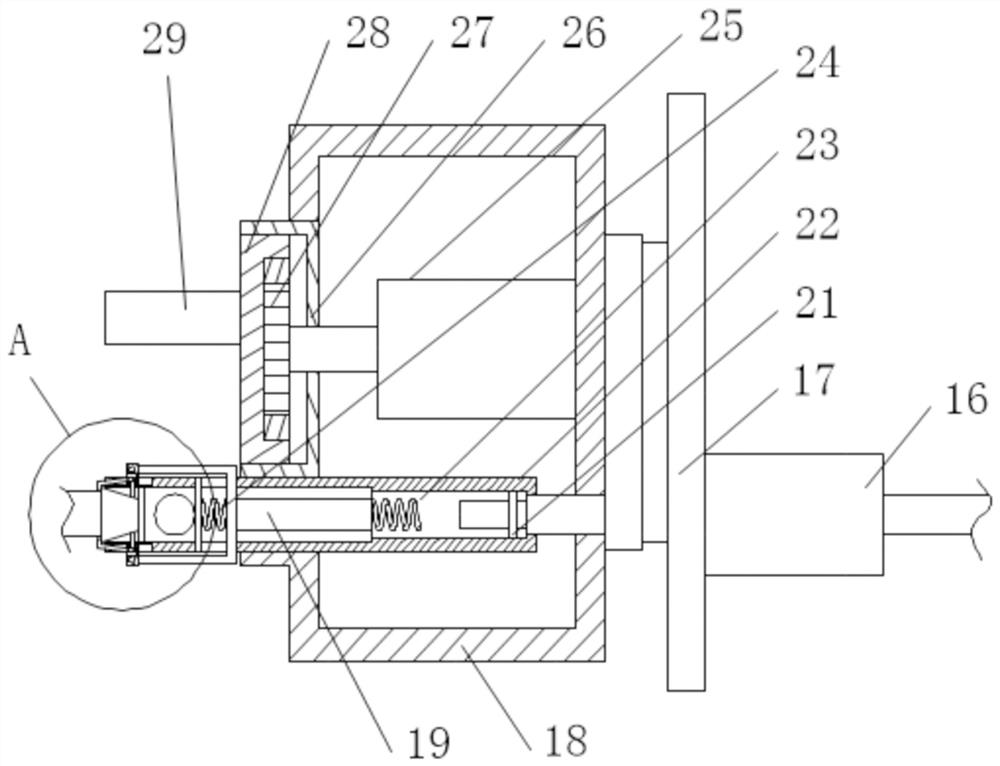

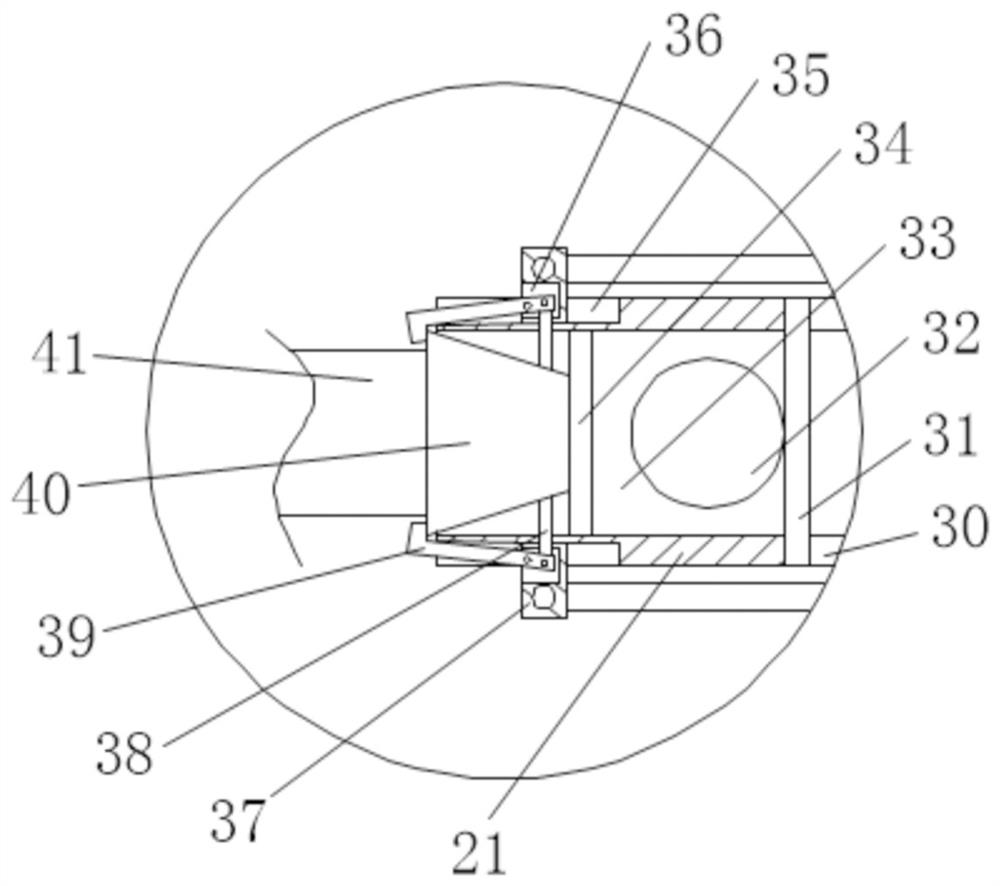

[0029] Such as Figure 1 to Figure 5 As shown, the present embodiment includes a frame 1 and a baffle plate 17. A primary cylinder 12 is horizontally arranged on the frame 1, a guide rod 13 is provided on the primary cylinder 12, and a side wall of the baffle plate 17 is provided with a In the fastening head 18 docked with the intake pipe 41, the output end of the primary cylinder 12 moves through the baffle 17 and is placed in the fastening head 18. On the other side wall of the baffle 17, a guide cylinder 14 is horizontally arranged, and the guide rod The end of 13 is placed in the guide cylinder 14; there is a cavity inside the fastening head 18, and the end of the follower rod 22 coaxial with the output end of the primary cylinder 12 passes through the fastening head 18 and is placed in the cavity. Along the axis of the follower rod 22, there is a cavity 23 in it, the cavity 23 is closed to one end of the primary cylinder 12 and the other end is open, the push rod 19 is pl...

Embodiment 2

[0036] Such as Figure 1 to Figure 5 As shown, on the basis of Embodiment 1, in order to increase the flexibility of the mechanical arm, this embodiment removes the lateral adjustment mechanism provided on the frame 1 to control the lateral movement of the fastening head 18, and also controls the lateral movement of the fastening head 18 on the frame 1 respectively. It is equipped with a circumferential adjustment mechanism and a longitudinal adjustment mechanism;

[0037]Wherein the circumferential adjustment mechanism includes an adjustment motor 25 arranged inside the fastening head 18, a chuck 26 is arranged on the side wall of the fastening head 18 facing away from the push-pull cylinder, and the output end of the adjustment motor 25 moves through the fastening head 18 Enter into the chuck 26 behind the side wall, the output end of the adjustment motor 25 is provided with an adjustment gear 27, a turntable 28 is arranged in the chuck 26, and a toothed belt cooperating wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com