Combined nozzle for oil pipe

A nozzle and oil pipe technology, which is applied in the field of oil pipe combined nozzles, can solve the problems of foreign matter entering the oil pipe through the nozzle, no flow rate adjustment structure, and nozzle without partition, etc., to achieve strong design ideas, efficient use of space structure, and strong linkage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

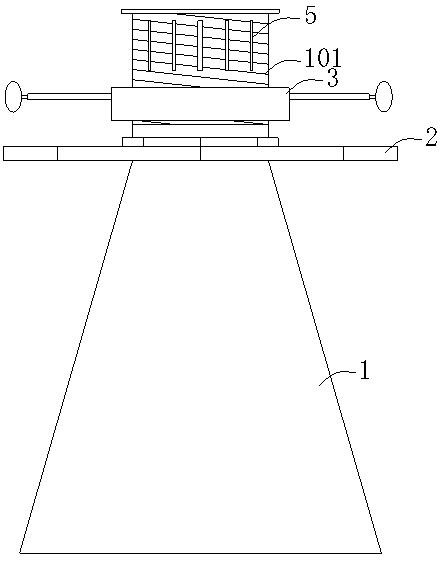

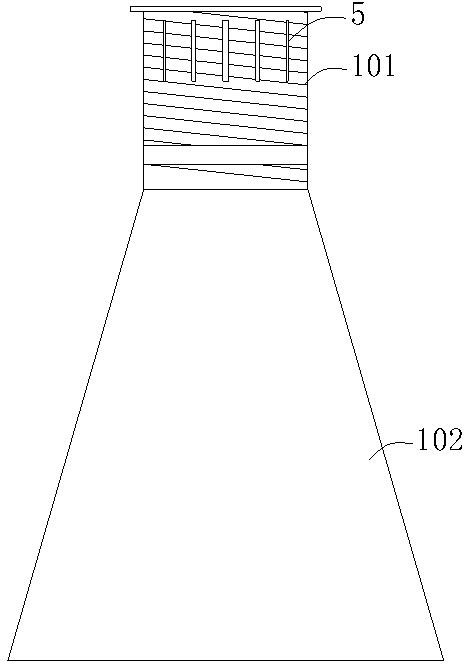

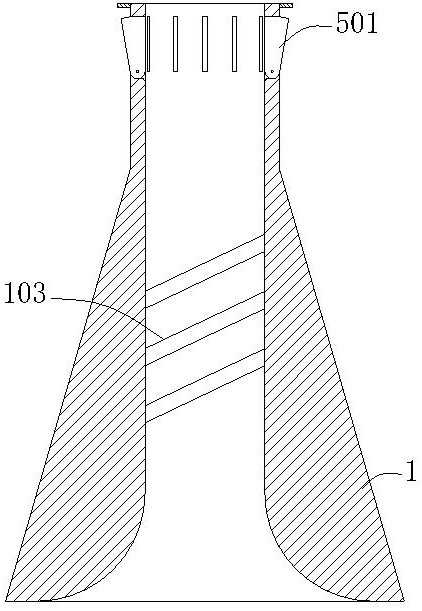

[0037] Example: such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 Figure 11 and Figure 12 As shown, an oil pipe combined nozzle of the present invention includes a main body 1. The main body 1 is composed of a cylindrical part 101 and a vertebral part 102 at the bottom of the cylindrical part 101. The middle part of the inner cavity of the vertebral part 102 is provided with a threaded part 103. The outer surface of 101 is provided with an external thread, the external thread is threaded with a fastening mechanism 3 and a fixed mechanism 2 at the bottom of the fastening mechanism 3, the top of the fastening mechanism 3 is provided with a partition mechanism 4, and the top of the cylindrical part 101 is provided with a Flow regulating mechanism 5.

[0038] Wherein, the fixing mechanism 2 includes a nut 201 threadedly connected with the external thread and a polygonal piece 202 fixedly arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com