Closestool flushing system

A toilet and pressure technology, applied in the field of sanitary ware, can solve problems affecting user experience, high noise, and low flushing force, and achieve the effects of avoiding gas-liquid mixing and dry spraying, reducing noise, and improving flushing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

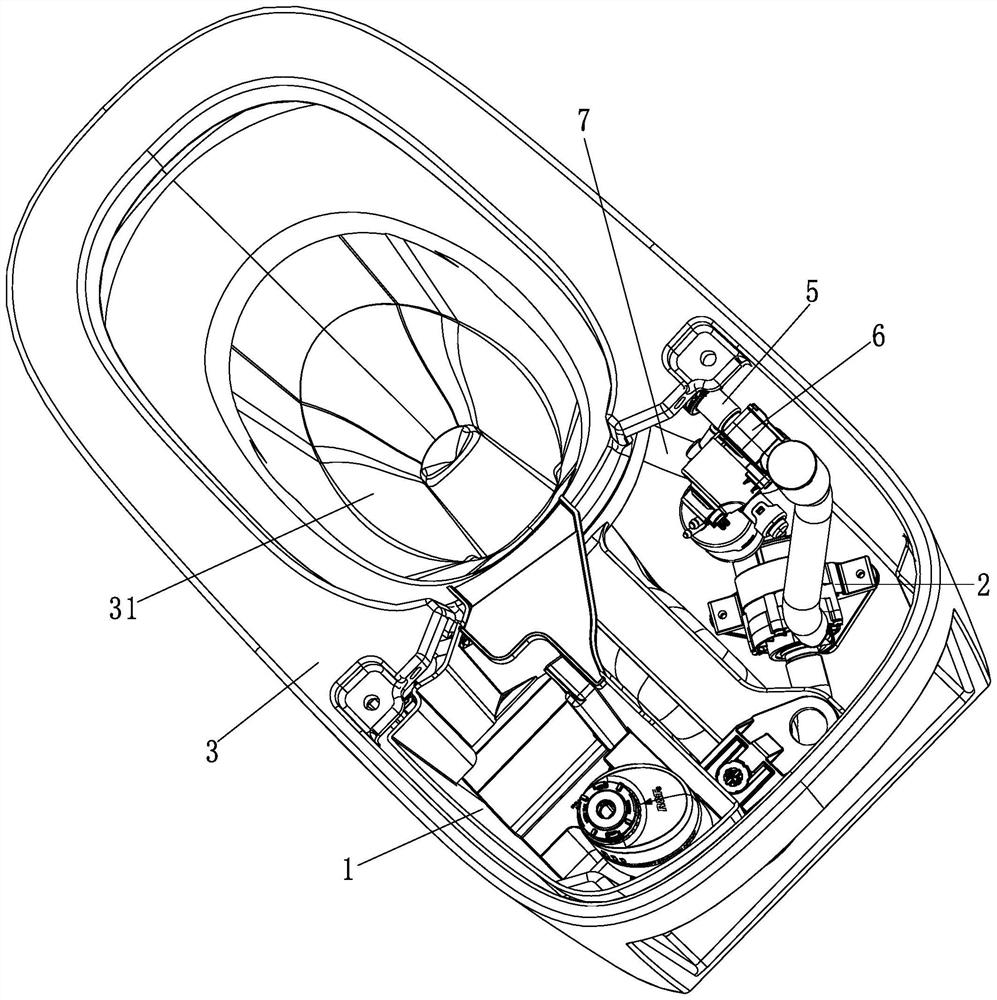

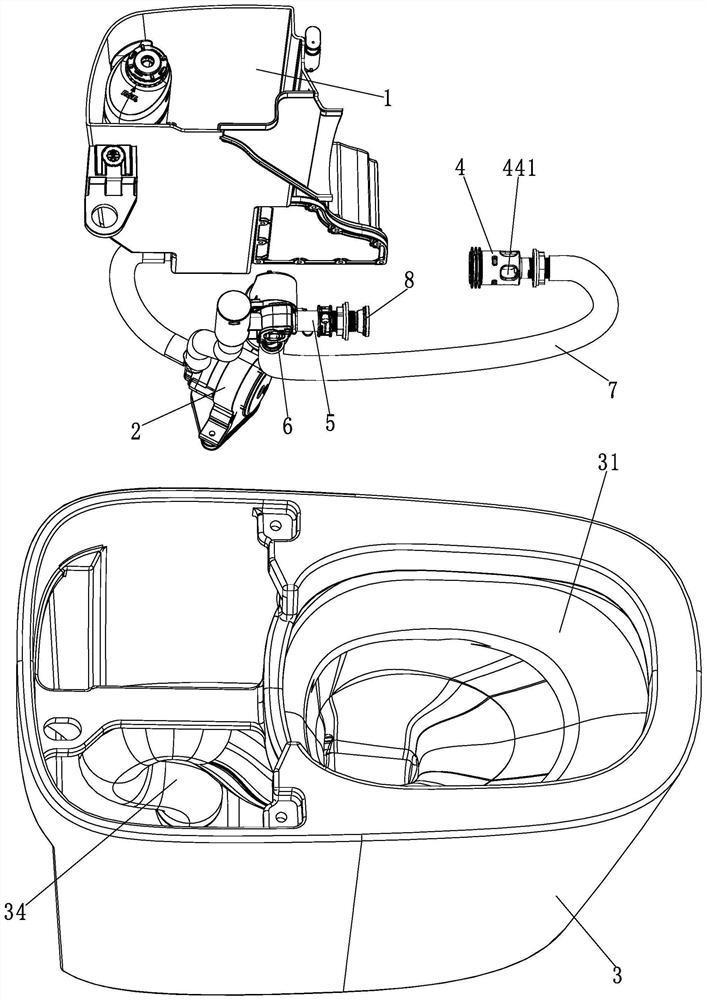

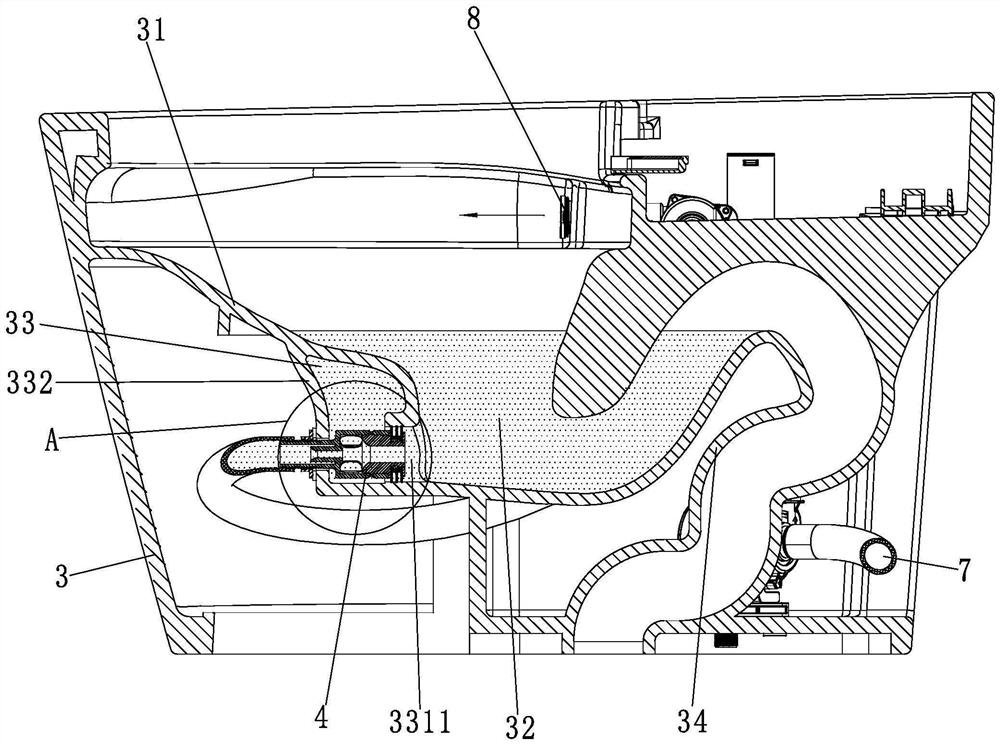

[0033] See Figure 1 to Figure 6 As shown, a kind of toilet flushing system of the present embodiment comprises:

[0034] A pressure water source for providing pressure water;

[0035] Toilet 3, toilet 3 has bedpan 31, and the bottom of bedpan 31 has the water sealing water that is used to form water seal 32, and the bottom of bedpan 31 is provided with a water storage chamber 33, and water storage chamber 33 has the anterior cavity wall 331 that is arranged oppositely and rear The chamber wall 332, the front chamber wall 331 is provided with spray holes 3311, the rear chamber wall 332 is provided with installation holes 3321, the water storage chamber 33 communicates with the water seal 32 through the spray holes 3311;

[0036] The flow increasing device 4 is installed in the installation hole 3321, the inlet of the flow increasing device 4 is connected with the pressure water source, the pressure water source provides pressure water to the flow increasing device 4, and the ...

Embodiment 2

[0053] Embodiment 2 (not shown)

[0054] This embodiment is basically the same as Embodiment 1, the only difference being:

[0055] In this embodiment, the flow increasing device is only provided with injection channels, and the cross-sectional area of the outlet of the injection channel (that is, the outlet of the flow increasing device) is smaller than the cross-sectional area of the injection hole, and the outlet of the injection channel and the inlet of the injection hole are arranged at intervals ( That is, the outlet of the flow increasing device and the inlet of the injection hole are arranged at intervals), and the outlet of the injection channel sprays water flow to the inlet of the injection hole. By adopting this structural design, the flow increasing device of this embodiment can make use of the Venturi principle to make the storage The water in the water chamber is sucked into the inlet end of the jet hole, and the water sucked into the inlet end of the jet ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com