Underwater cable laying system and method

A cable laying and cable laying technology, which is applied in the field of underwater cable laying systems, can solve problems such as mechanical parts deformation, damage, loss, and submarine cable crushing, and achieve the goals of improving safety and reliability, reducing energy consumption, and increasing operational complexity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

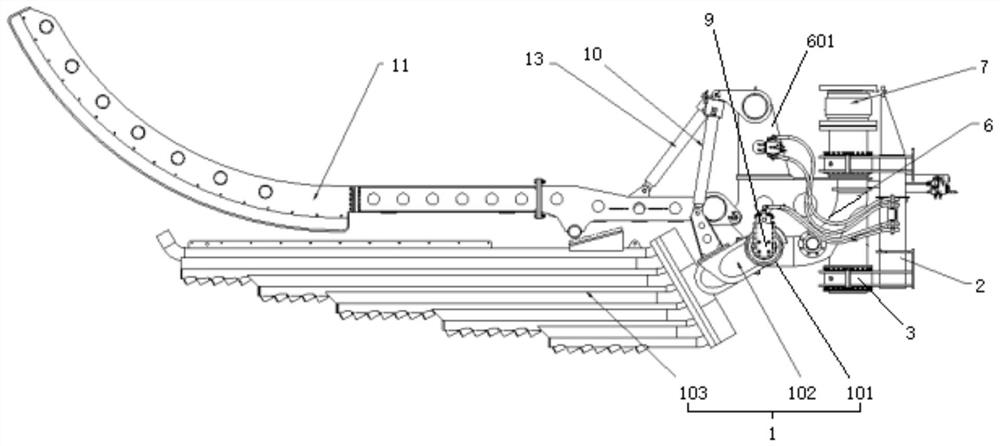

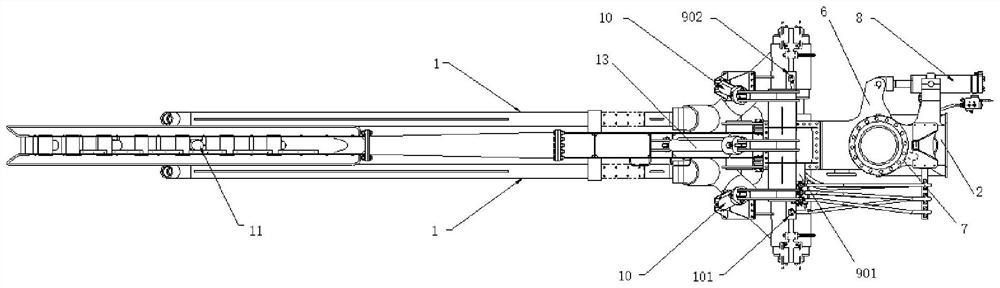

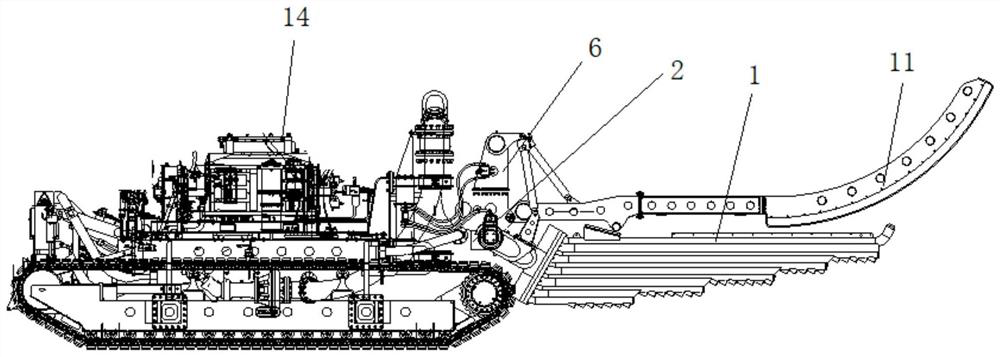

[0050] as attached Figure 1-24 As shown, the present invention provides an underwater cable laying system, comprising a trencher 14 and a coulter assembly arranged at the tail of the trencher 14, and the coulter assembly includes a bracket 6 and jet plows arranged on both sides of the bracket 6 The knife 1 and the cable presser 11 arranged in the middle of the two spray coulters 1 also include a linear moving assembly 9 and a rotating assembly 10, and each of the two spraying coulters 1 is arranged on the support 6 through a set of linear moving assemblies and rotating assemblies Two groups of linear moving components 9 are coaxially arranged to adjust the relative width and relative position of the two jet coulters 1, and the rotating component 10 drives the jet coulter 1 to rotate with the moving direction of the linear moving component as the axis to lower and lower the jet coulter 1. The lifting action also includes the base 2 connecting the bracket 6 and the trencher 14,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com