Automatic fault detection method for crane operating rod controller

An automatic detection and operating rod technology, applied in the direction of transportation and packaging, load suspension components, safety devices, etc., can solve the problems of difficult judgment, inconvenient video, limited level, etc., and achieve the effect of saving maintenance time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The specific embodiments provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

[0038] Such as Figure 1-9 As shown, a fault automatic detection method for a crane joystick controller includes the following:

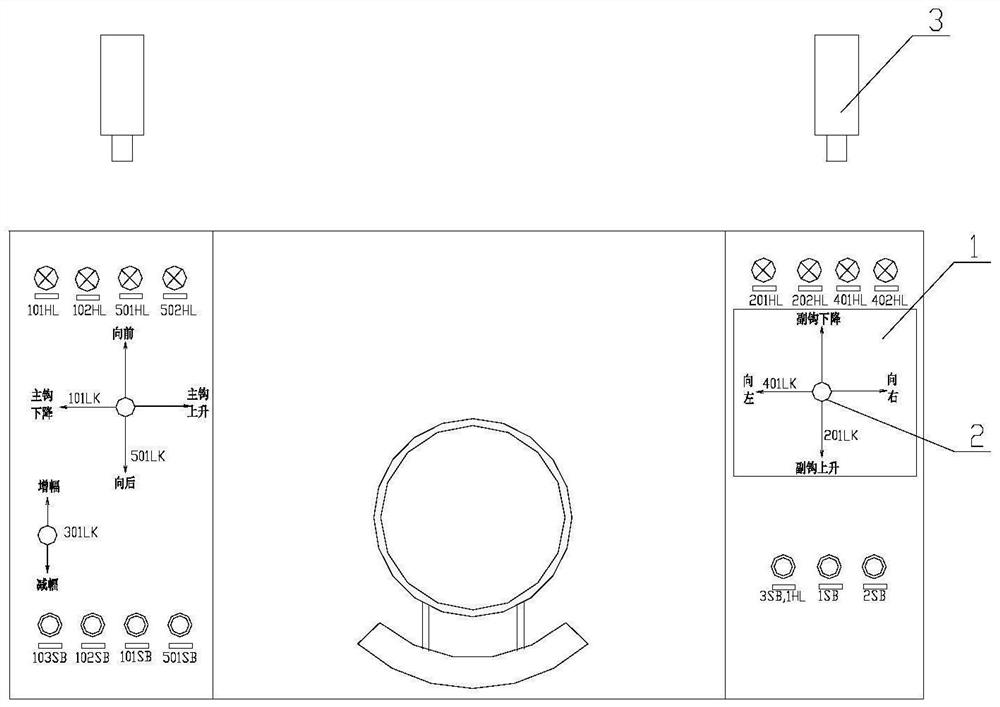

[0039] Step 1. Install the camera 3 directly above the crane operating platform, and set the panel 1 on the joystick controller 2 of the linkage platform, and the joystick controller 2 is located at the center of the panel 1.

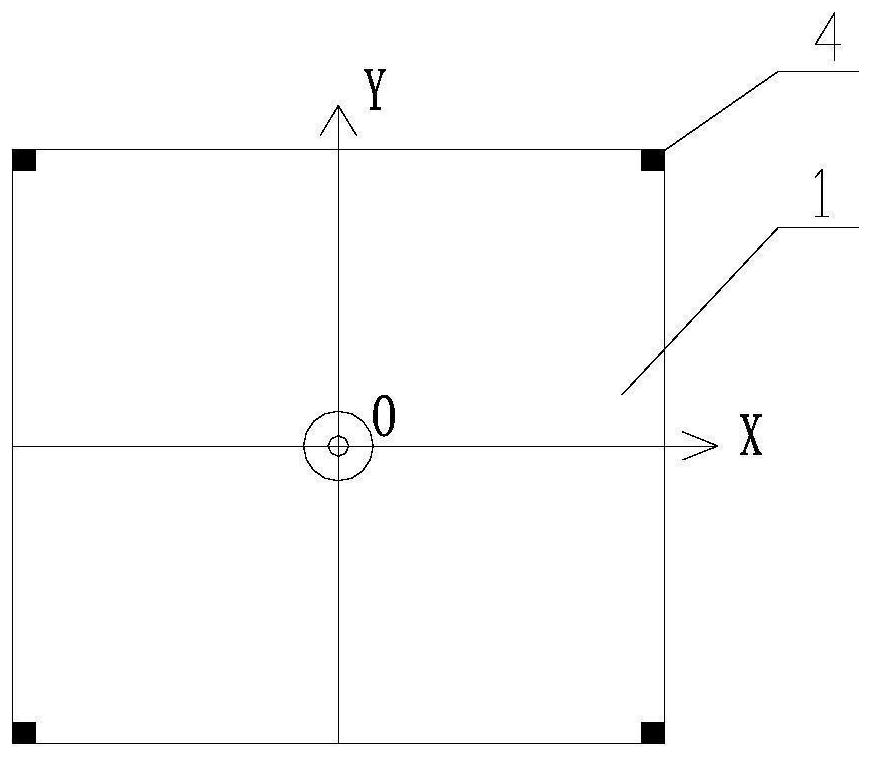

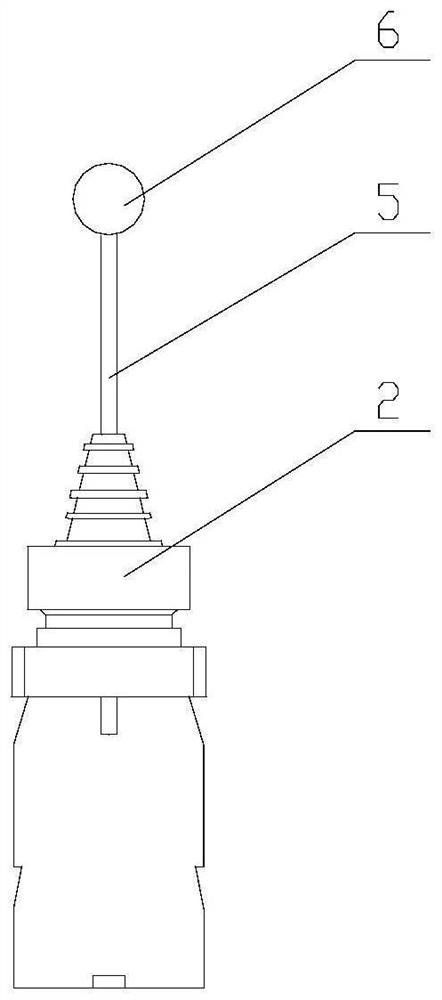

[0040] Step 2: Set marker one 4 on the panel 1 of the crane operating rod controller 2 , and set marker two on the handle 6 of the operating rod controller 2 .

[0041] The disk surface 1 of the crane joystick controller 2 is a square with a white background. If the linkage platform is a white paint surface, the disk surface 1 can be a square area on the upper part of the linkage platform, or a metal square with a white background can be fixed on the linkage platform. Or a non-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com