Automobile injection molding part conveying device

A technology for conveying devices and injection molded parts, applied to conveyors, household components, mechanical conveyors, etc., can solve the problem of high price, achieve simple structure, reduce falling speed, and good processing rhythm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

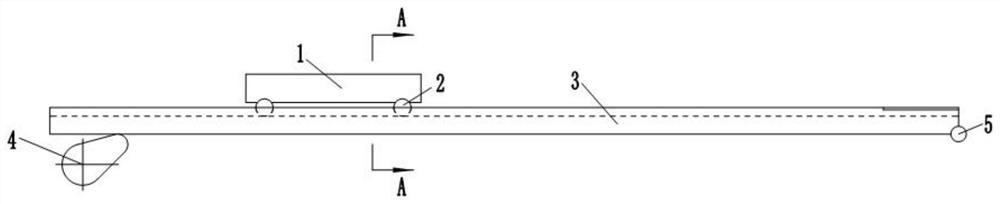

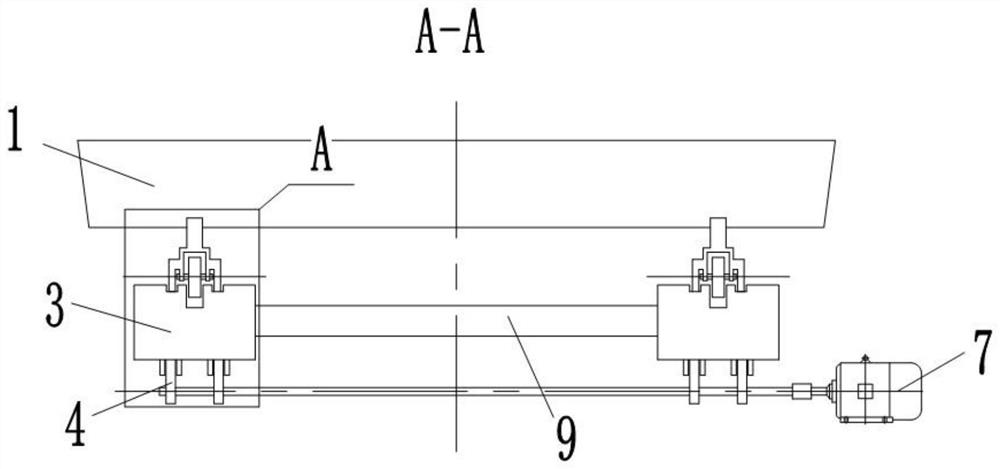

[0037] The present invention is a conveying device for injection molded parts of automobiles, which comprises a conveying car, two rows of casters 2 are arranged under the conveying car 1, two rows of guide rails 3 are arranged under the casters as bearing bodies, and a cam 4 is arranged under one end of the guide rails. The keyway of the output shaft of the motor is matched. The motor is a servo motor. The cam raises the guide rail to a certain inclination angle, and the component force of gravity along the guide rail is used to move down the guide rail. After the transfer vehicle advances to a station on the production line, the servo motor reverses and the guide rail falls to a flat state. At this moment, the worker can continue to process the products on the station. A hinge 5 is provided at the end of the guide rail, and the hinge 5 is hinged with the hinge bracket. The guide rail is provided with accommodating groove 6 for the caster to be embedded in, and the two ends ...

Embodiment 2

[0039]The difference from Embodiment 1 is that instead of the cam, the wedge block 15 is arranged below one end of the guide rail, and the contact position between the guide rail and the wedge block is a smooth transition angle. It is connected with the piston rod of the cylinder; the end of the same side of the guide rail and the hinge is provided with an arc surface 11 with an upward opening; shaft connection.

Embodiment 3

[0041] The difference from Embodiment 1 is that: the two sides of the transport vehicle are provided with deceleration rods 12, and the end of the guide rail is provided with a buffer rod 13 used in conjunction with the deceleration rod, and the buffer rod can rotate around a torsion spring 14.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com