A design method of external power supply module for test model against high emission overload

A technology of external power supply and test model, which is applied in the direction of offensive equipment, weapon testing, geometric CAD, etc., can solve the problems of increasing the capacity and volume of the energy storage module, the length of the flight time, and the complexity of the launch preparation process, so as to increase the payload ratio, high economy, and the effect of ensuring launch safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

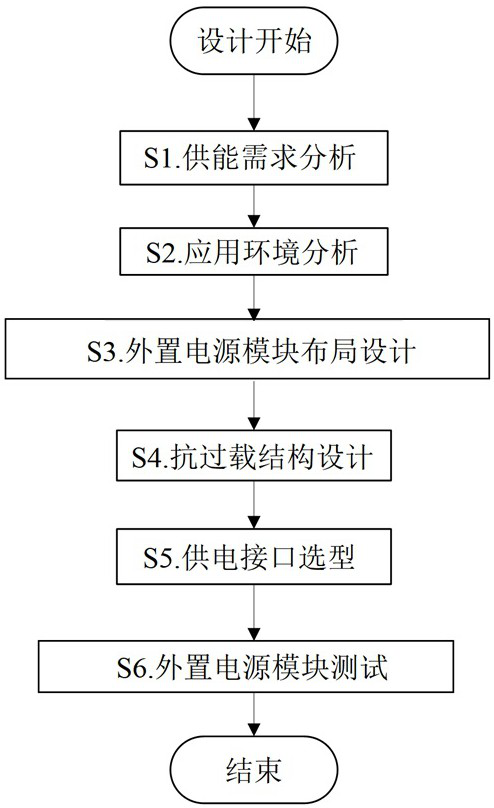

Method used

Image

Examples

Embodiment 1

[0106] The application scenario of this embodiment is the launch environment of a secondary light gas gun, and a test model with aerodynamic parameter measurement function is launched. The built-in electrical components of this test model can realize 4-channel parameter measurement, independent power supply for more than 10 seconds, and data logging. From the time the test model enters the closed launch environment, the test preparation time is 4-5 hours. In order to fill the continuous power supply demand of the test model in the test preparation stage, and maintain the built-in power supply capacity and the distribution of the center of mass of the test model, an external power supply that can be thrown as a whole is designed according to the design method of the external power supply module of the test model with resistance to high emission overload of the present invention. .

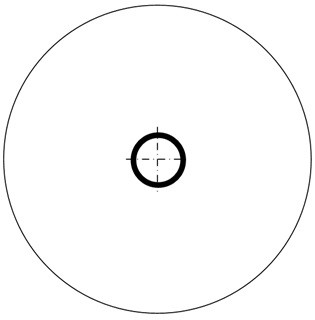

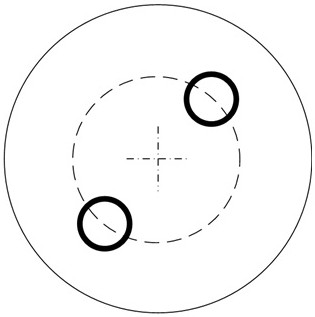

[0107] First, according to the energy supply demand analysis in step S1, the obtained energy su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com