Omnibearing digital management and control system and method for discrete tightening manufacturing of rail transit

A rail transit and management and control system technology, applied in general control systems, control/regulation systems, program control, etc., can solve problems such as time-consuming, large footprint of assembly workshops, and inability to maintain intelligent tightening equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] This embodiment provides an all-round digital management and control system for rail transit discrete tightening manufacturing.

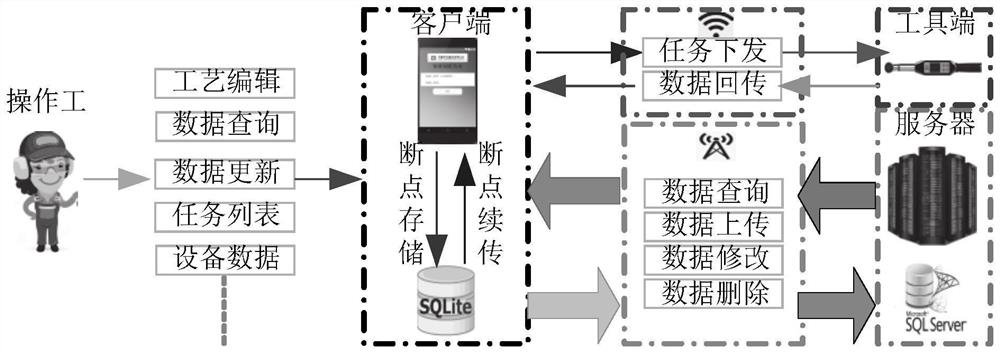

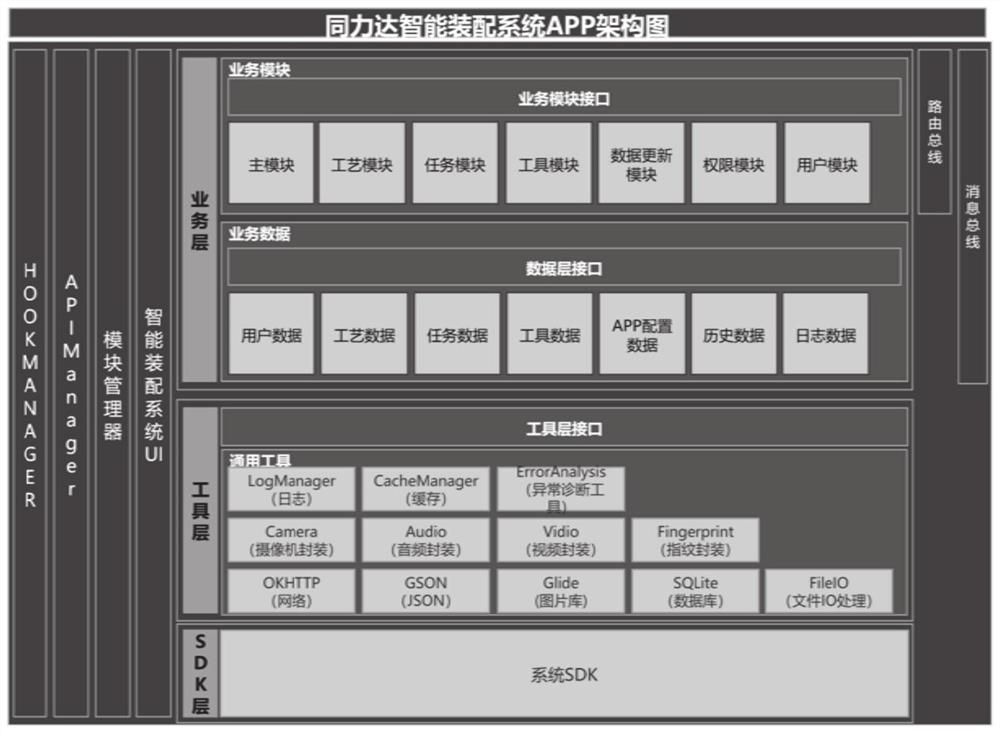

[0055] Such as figure 1 As shown, a comprehensive digital management and control system for rail transit discrete tightening manufacturing, including:

[0056] The intelligent tool cabinet management unit is used to manage the tool cabinet, and the tool cabinet stores the intelligent digital display torque wrench and the handheld terminal;

[0057] The equipment calibration unit is used to calibrate the intelligent digital display torque wrench, obtain the calibration information of the intelligent digital display torque wrench, and measure the accuracy of the sensor on the intelligent digital display torque wrench;

[0058] The handheld terminal assembly unit controls the intelligent digital display torque wrench by releasing hot spots through the handheld terminal, and uploads the assembly data to the server;

[0059] The server is connecte...

Embodiment 2

[0102] This embodiment provides an all-round digital control method for rail transit discrete tightening manufacturing.

[0103] An all-round digital management and control method for rail transit discrete tightening manufacturing, including:

[0104] The tool cabinet stores intelligent digital display torque wrench and handheld terminal;

[0105] Calibrate the intelligent digital display torque wrench, obtain the calibration information of the intelligent digital display torque wrench, and measure the accuracy of the sensor on the intelligent digital display torque wrench;

[0106] Control the intelligent digital display torque wrench by releasing the hot spot through the handheld terminal, and upload the assembly data to the server;

[0107] The server analyzes and processes the uploaded data to judge whether the tightening operation of the intelligent digital display torque wrench is qualified.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com