Pipeline defect ultrasonic detection device

A detection device, ultrasonic technology, applied in measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, using sound waves/ultrasonic waves/infrasonic waves for material analysis, etc., can solve problems such as cracks, difficult realization, and difficult detection of pipeline defects , to improve the accuracy of the

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

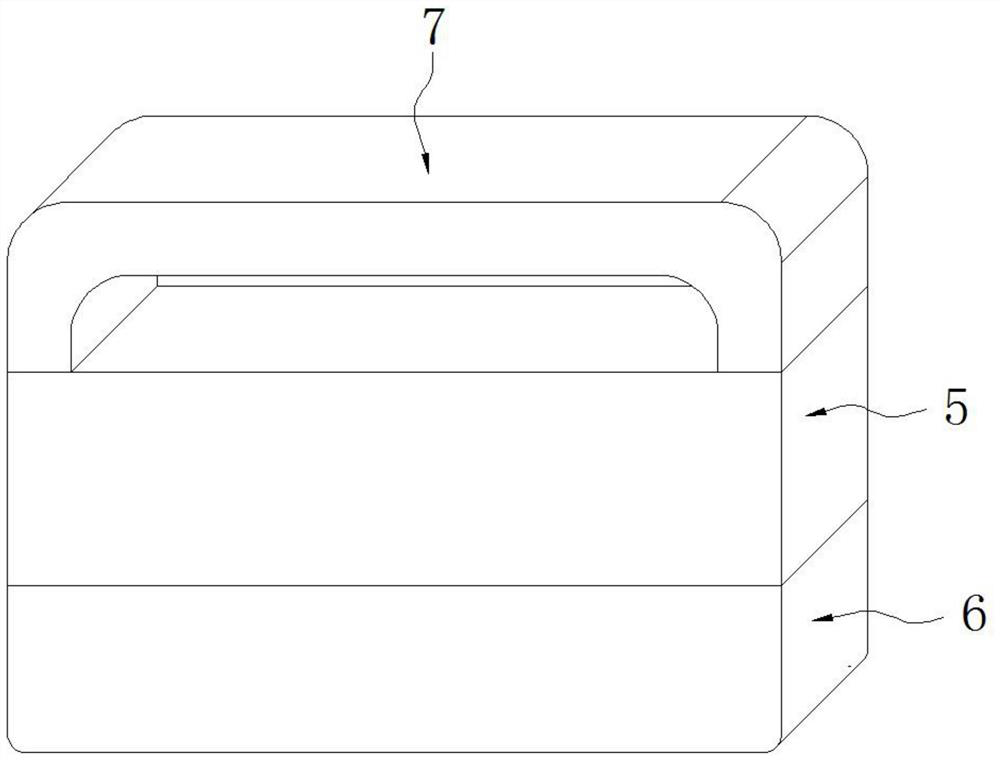

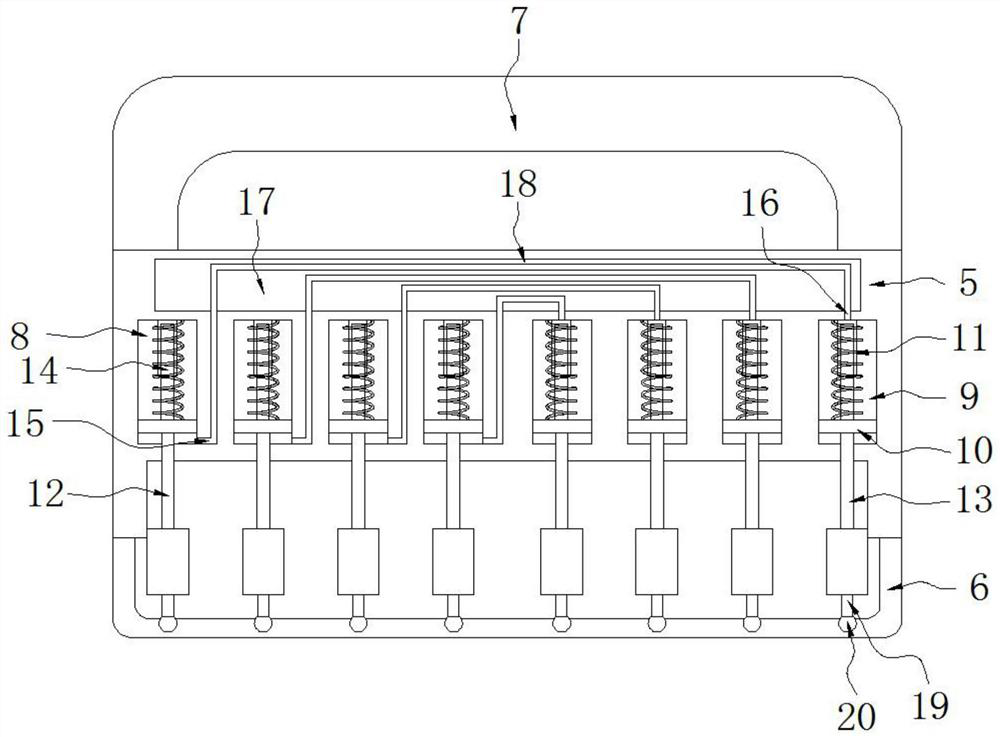

[0021] As a preferred embodiment of the present invention, a handle 7 is fixedly installed on the top of the mounting base 5 .

[0022] As a preferred embodiment of the present invention, the spring 11 is sheathed on the telescopic rod 14 , and the spring 11 and the telescopic rod 14 are fixedly connected with the movable seat 10 .

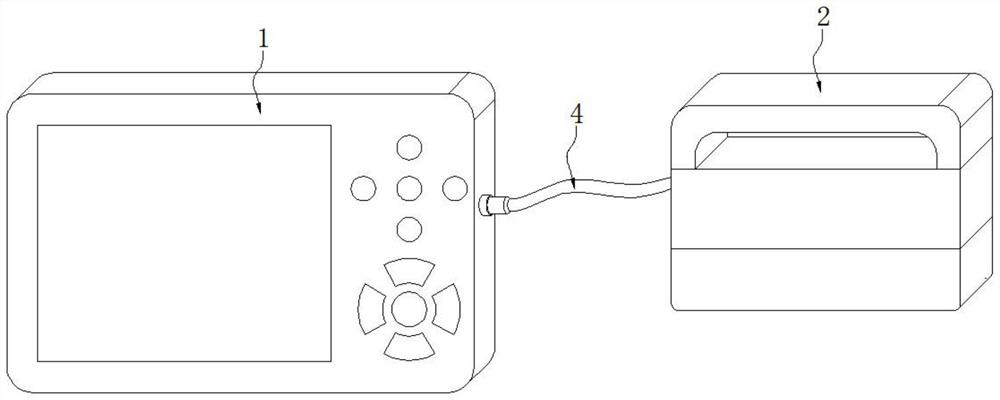

[0023] As a preferred embodiment of the present invention, a transmission line 4 is connected to the main body 1 of the ultrasonic testing device, and the main body 1 of the ultrasonic testing device is connected to the detection head 3 through the transmission line 4 .

[0024] As a preferred embodiment of the present invention, the detection head 3 is fixedly embedded in the bottom of the mounting base 5 .

[0025] As a preferred embodiment of the present invention, the top of the convex ejection groove 9 is filled with hydraulic oil.

[0026] As a preferred embodiment of the present invention, when in use, hold the handle 7 and forcefully atta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com