Single-face connecting bolt

A technology for connecting bolts and one side, which is applied to rivets and other directions, can solve the problems of large installation torque and low connection strength, and achieve the effect of small installation torque, high connection strength and improved strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

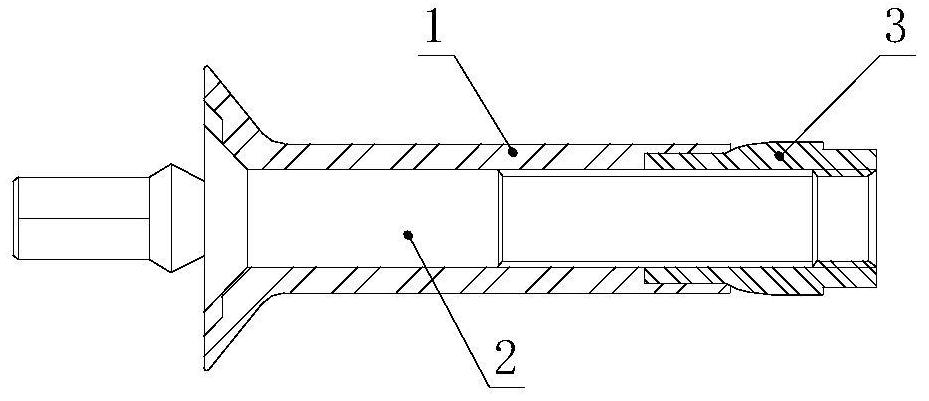

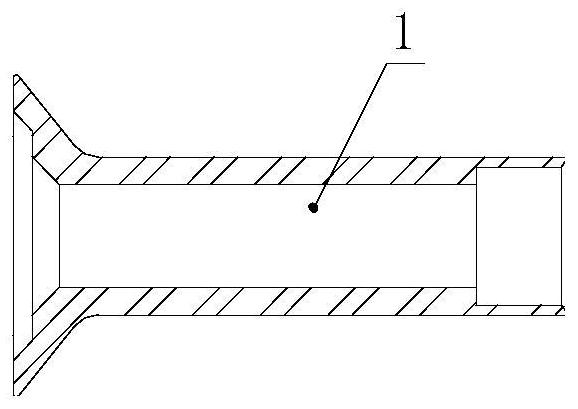

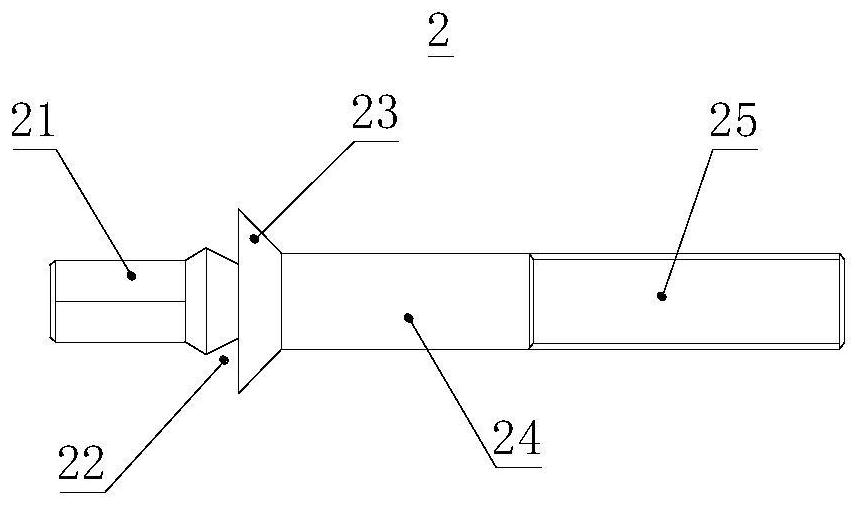

[0035] combined with figure 1 and Figure 4 , this embodiment provides a single-sided connecting bolt, including a nail sleeve 1, a core rod 2 and an extrusion nut 3; the extrusion nut 3 includes a first cylindrical section 31 and a cone section 32 connected in sequence, The outer diameter of a cylindrical section 31 is greater than the inner diameter of the nail sleeve 1, and the end of the cone section 32 away from the first cylindrical section 31 is inserted in the nail sleeve 1; one end of the core rod 2 is movably inserted in the The nail sleeve 1 is screwed to the extrusion nut 3 , and the extrusion nut 3 is driven to move to the other end of the core rod 2 by rotating the core rod 2 .

[0036] continue to combine figure 1 Specifically, the nail sleeve 1 is integrally formed in the shape of a countersunk screw, so as to prevent the outer end of the screw sleeve from protruding from the aircraft body and affecting the aerodynamic fluidity of the aircraft shape.

[0037...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com