Structure of anti-seismic, flood-proof and explosion-proof door of precise and ultra-precise numerical control machine tool manufacturing workshop

A technology of CNC machine tools and manufacturing workshops, applied to windows/doors, building components, sealing devices, etc., can solve the problems of not being able to achieve the airtight effect, equipment immersion, damage, etc., and achieve the effect of improving the effect of flood control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

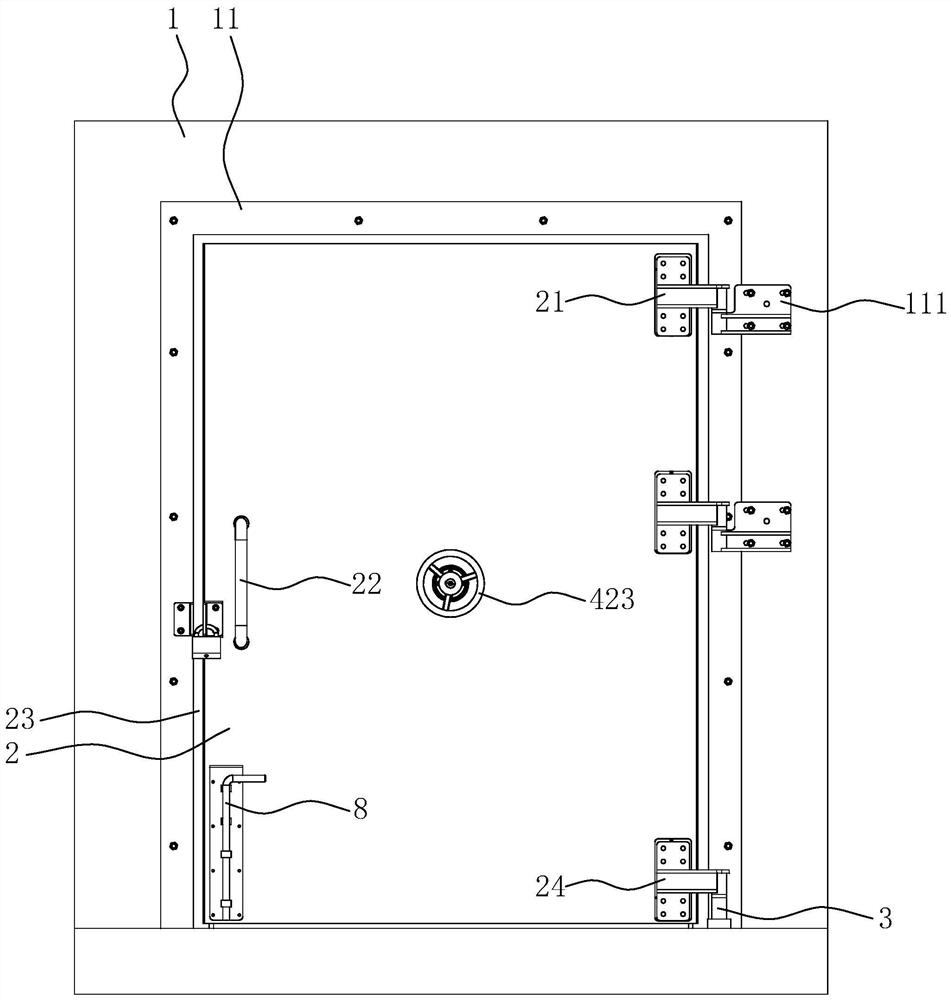

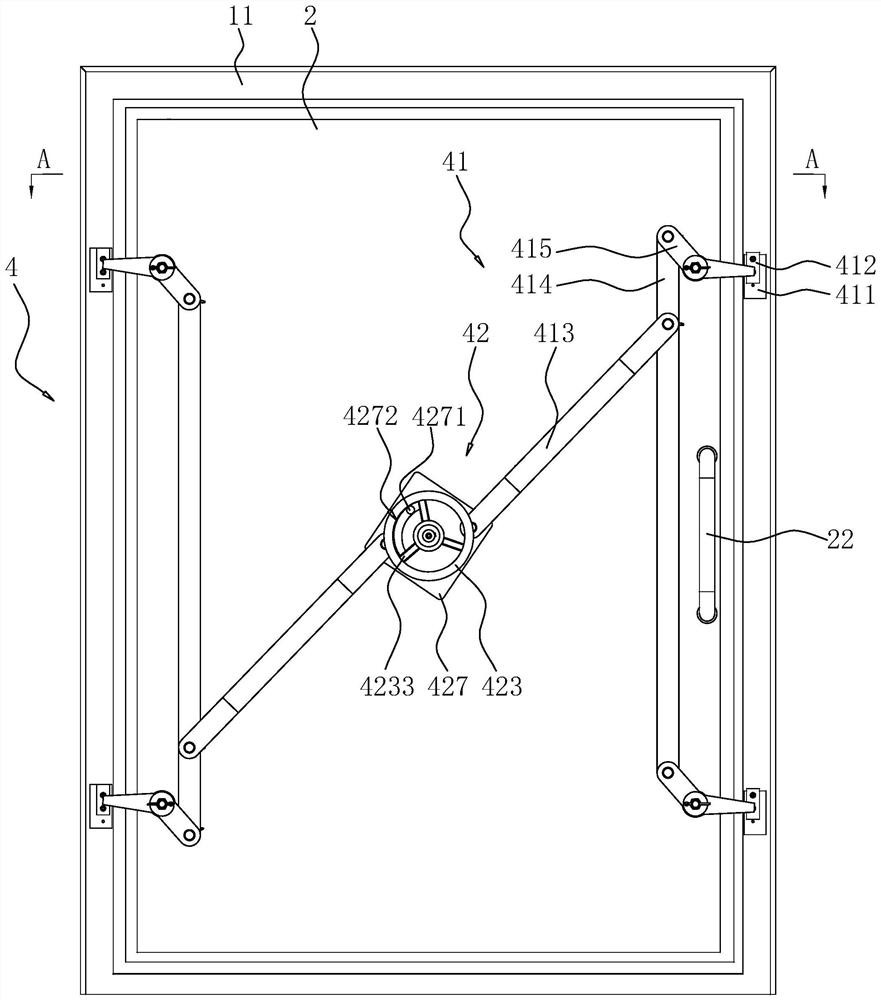

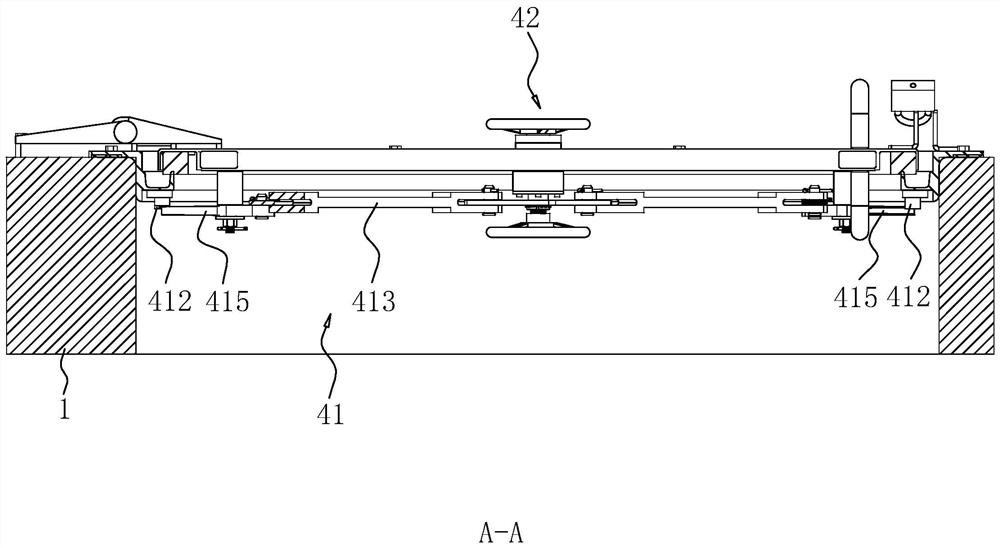

[0041] The embodiment of the present application discloses a structure of an anti-seismic, flood-proof and explosion-proof door of a precision ultra-precision numerical control machine tool manufacturing workshop. refer to figure 1 The structure of the flood control and explosion-proof door includes a wall 1 formed by pouring concrete, the wall 1 is fixedly connected with a door frame 11, the door frame 11 is integrally cast with the wall 1, and the door 2 is installed in the door frame 11. One side of the door body 2 is fixedly connected with a plurality of first hinges 21 by screws, and one side of the door frame 11 is fixedly connected with a plurality of second hinges 111, and each first hinge 21 corresponds to a second hinge 111, and each The first hinges 21 are hinged with the corresponding second hinges 111 .

[0042]Two side surfaces of the door body 2 are fixedly connected with handles 22 , and the handle 22 is located at an end of the door body 2 away from the first...

Embodiment 2

[0062] The embodiment of the present application discloses a structure of an anti-seismic, flood-proof and explosion-proof door of a precision ultra-precision numerical control machine tool manufacturing workshop. refer to Figure 8 , the difference from Embodiment 1 is that, in order to further restrict the occurrence of water leakage between the fixed sleeve 421 and the rotating shaft 422 , a limiting assembly 9 is connected between the fixed sleeve 421 and the rotating shaft 422 .

[0063] The inner side wall of the fixing sleeve 421 is provided with a ring of placing grooves 4211 , and a cardboard ring 91 is clamped in the placing grooves 4211 . One side wall of the placement groove 4211 is provided with four installation grooves 4212 , and the other side wall of the placement groove 4211 is provided with four adjustment grooves 4213 , the installation grooves 4212 and the adjustment grooves 4213 are located on both sides of the cardboard ring 91 . One mounting groove 421...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com