Solidified soil stirring field and solidified soil backfill construction method in narrow high backfill area

A construction method and technology for solidifying soil, applied in the directions of chemical instruments and methods, excavation, fertilization devices, etc., can solve the problems of inability to perform construction by personnel and machinery, high backfilling depth, and narrow backfilling area, so as to achieve reasonable distribution and reuse. , the effect of short curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

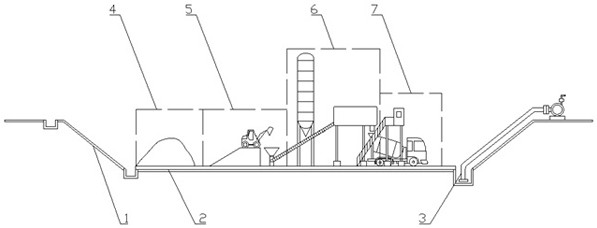

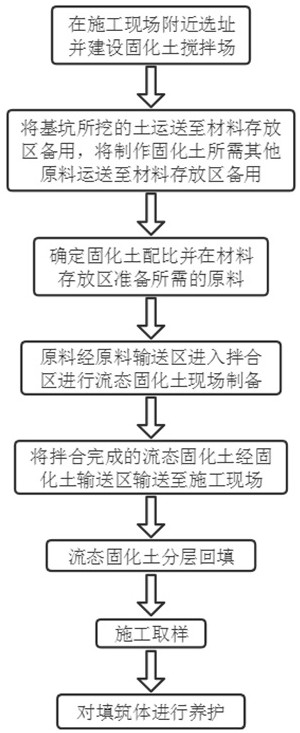

[0058] This embodiment discloses a solidified soil mixing field and the positioning of the solidified soil backfill construction method in the narrow high backfill area, such as figure 1 As shown, it includes a solidified soil mixing field, which is characterized in that it is arranged on a flat place near the construction site, surrounded by slopes 1 that have been treated with grading, and a concrete hardened layer 2 that is high in the middle and low in the surroundings on the bottom surface. Drainage system 3, material storage area 4, raw material delivery area 5, mixing area 6 and solidified soil delivery area 7 are set in the mixing field.

[0059] The hardened concrete layer 2 is processed by C20 concrete, and the hardened concrete layer 2 has a thickness of 10cm-20cm.

[0060] Drainage system 3 comprises drainage ditches, sump well and the water pump that water is drawn out from the sump well.

[0061] A construction method for backfilling solidified soil in a narrow ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com