Laminated glass and head-up display system

A technology of laminated glass and glass plate, which is applied in the field of head-up display, can solve the problems of low reflectivity of P-polarized light, poor smoothness of P-polarized light reflection spectrum, and smoothness of P-polarized light reflection spectrum of laminated glass, so as to improve user experience , Reduce the effect of blue light hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

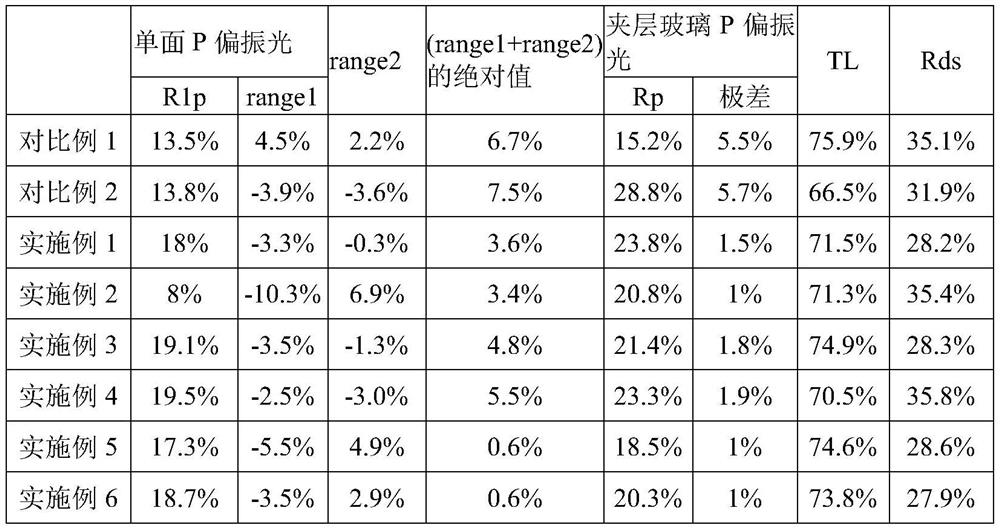

Embodiment 1

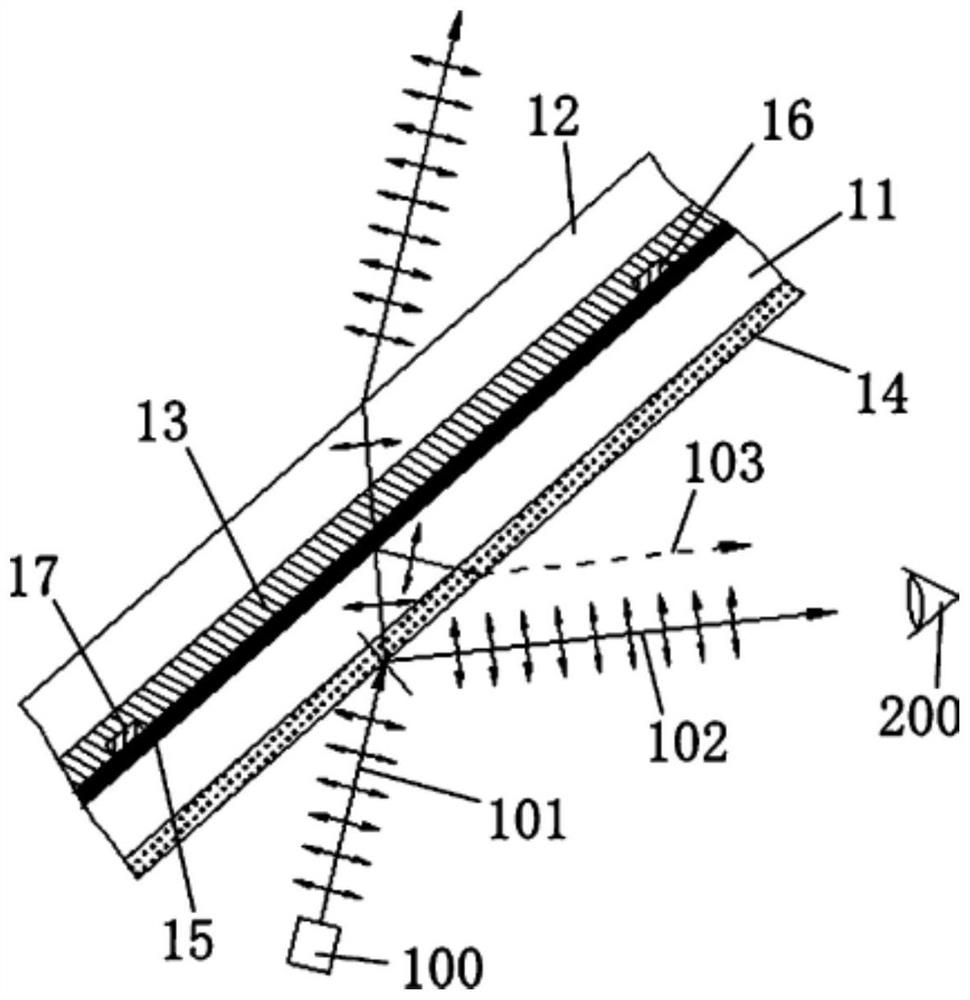

[0242] Laminated glass structure: first transparent nano film / inner glass plate 11 / PVB / second transparent nano film / outer glass plate 12.

[0243]The first transparent nano-film system: the fourth side of the laminated glass / TiSnOx (60nm) / SiO2 (100nm), where the refractive index of TiSnOx is 2.40.

[0244] The second transparent nano film system: the second surface of the laminated glass / ZnSnOx(43nm) / ZnO(10nm) / AgTi(7.4nm) / AZO(10nm) / ZnSnOx(96.7nm) / SiN(5nm). Here, the mass ratio of Ti in AgTi is 1%.

[0245] PVB thickness is 0.76mm.

[0246] The inner glass plate 11 is soda-lime-silica glass with a thickness of 1.6 mm.

[0247] The outer glass plate 12 is soda lime silica glass with a thickness of 2.1 mm.

Embodiment 2

[0249] Laminated glass structure: first transparent nano film / inner glass plate 11 / PVB / second transparent nano film / outer glass plate 12.

[0250] The first transparent nano-film system: the fourth side of the laminated glass / TiOx (5nm) / TiBiOx (100nm) / SiO2 (110nm), where the refractive index of TiBiOx is 2.41.

[0251] The second transparent nano film system: the second surface of the laminated glass / ZnSnOx(43.5nm) / Ag(11.9nm) / ZnSnOx(111.2nm) / Ag(6.0nm)

[0252] / ZnSnOx (40nm) / SiZrN (5nm).

[0253] PVB thickness is 0.76mm.

[0254] The inner glass plate 11 is soda-lime-silica glass with a thickness of 1.6 mm.

[0255] The outer glass plate 12 is soda lime silica glass with a thickness of 2.1 mm.

Embodiment 3

[0257] Laminated glass structure: first transparent nano film / inner glass plate 11 / PVB / second transparent nano film / outer glass plate 12.

[0258] The first transparent nano-film system: the fourth side of the laminated glass / ZnSnMgOx(19.5nm) / SiO2(10.0nm) / TiOx(10.0nm) / TiAlOx(38.0nm) / SiO2(111nm), here, the refraction of TiOx The refractive index of TiAlOx is 2.60, and the refractive index of TiAlOx is 2.50.

[0259] The second transparent nano-film system: the third side of the laminated glass / ZnSnNiOx(32.0nm) / Ag(5.0nm) / AZO(10nm) / SiN(58.0nm) / GZO(10nm) / Ag(5.0nm) / NiCr( 0.3nm) / AZO(10nm) / ZnSnOx(74.8nm) / SiN(5nm). GZO is gallium-doped zinc oxide.

[0260] PVB thickness is 0.76mm.

[0261] The inner glass plate 11 is aluminoborosilicate glass with a thickness of 0.7 mm.

[0262] The outer glass plate 12 is soda lime silica glass with a thickness of 2.1 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com