Production line for automatic packaging and stacking of plates

A production line and board technology, applied in the field of automatic packaging and palletizing production lines, can solve the problems of large space occupied by the reversing device and increased construction cost of the packaging line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

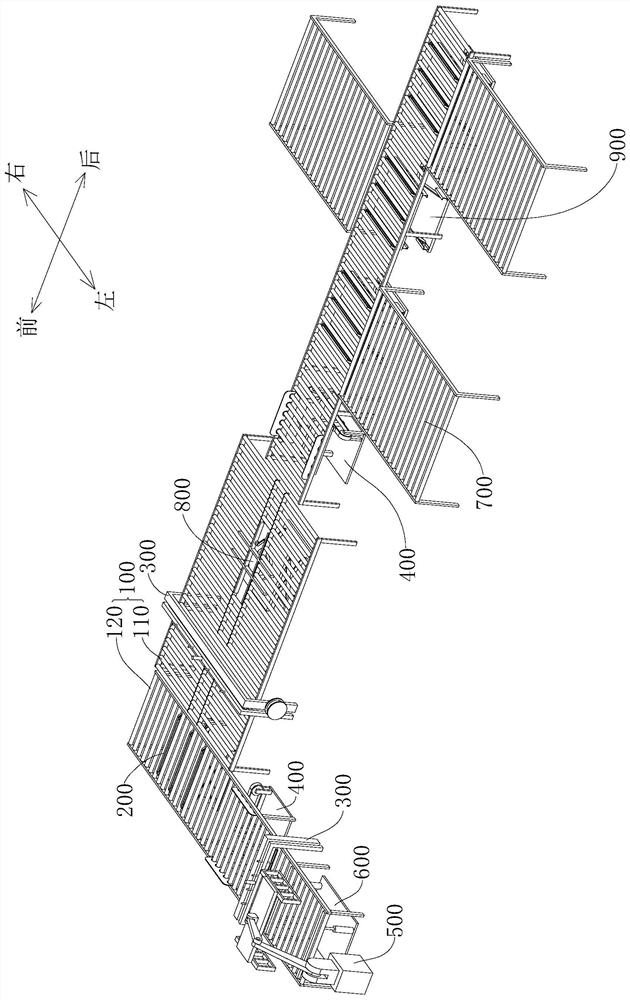

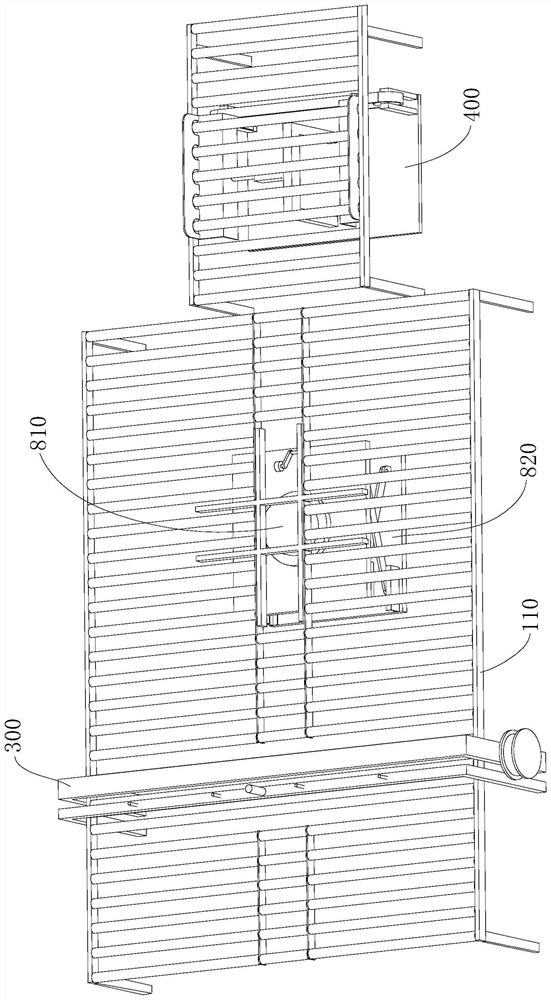

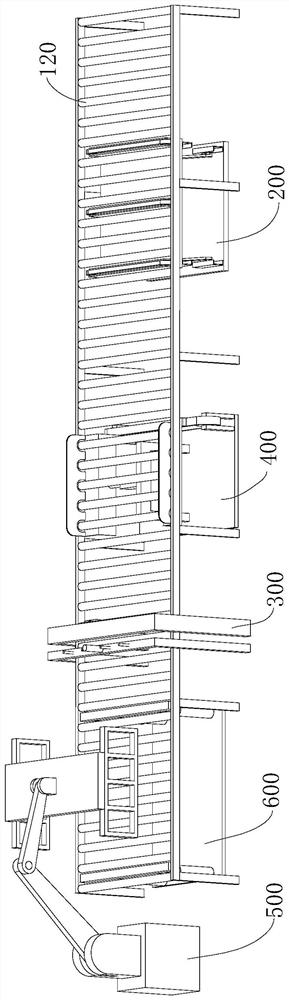

[0039] Embodiment one, see Figure 1-Figure 3 , the embodiment of the present invention provides a production line for automatic packing and palletizing of boards, including: a main production line 100 , a first transport device 200 and a packing device 300 .

[0040] Wherein, the main production line 100 includes a first sub-production line 110 and a second sub-production line 120, and the conveying direction of the first sub-production line 110 is conveyed from back to front, and the conveying direction of the second sub-production line 120 is conveyed from right to left , that is, the conveying direction of the first sub-production line 110 is arranged at right angles to the conveying direction of the second sub-production line 120, and the front end of the first sub-production line 110 is connected to the right end of the second sub-production line 120, that is, the plates on the first sub-production line 110 Finally, it will be transported to the entrance of the right end...

Embodiment 2

[0063] Embodiment 2, the embodiment of the present invention also provides a production line for automatic packing and palletizing of plates, including: a main production line 100, a first transport device 200 and a packing device 300, wherein the main production line 100 includes a first sub-production line 110 and the second sub-production line 120, the layout of the first sub-production line 110 and the second sub-production line 120 is roughly similar to Embodiment 1, the main difference is that: the first sub-production line 110 and the second sub-production line 120 can be conveyed by belts, chains The board conveying method realizes the conveying, so as to realize the conveying of the board, and the first transportation device 200 can be set as a mechanical clamp arm, and the board can be transported from the first sub-production line 110 to the second sub-production line 120 through the setting of the mechanical clamp arm , which can meet the needs of the production lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com