Logistics warehouse storage equipment and management system

A technology of storage management system and storage equipment, applied in the field of logistics storage storage equipment and management system, can solve the problems of damage, different stability, classification of stored items, etc., and achieve the effects of easy maintenance, cost reduction and high lubrication.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

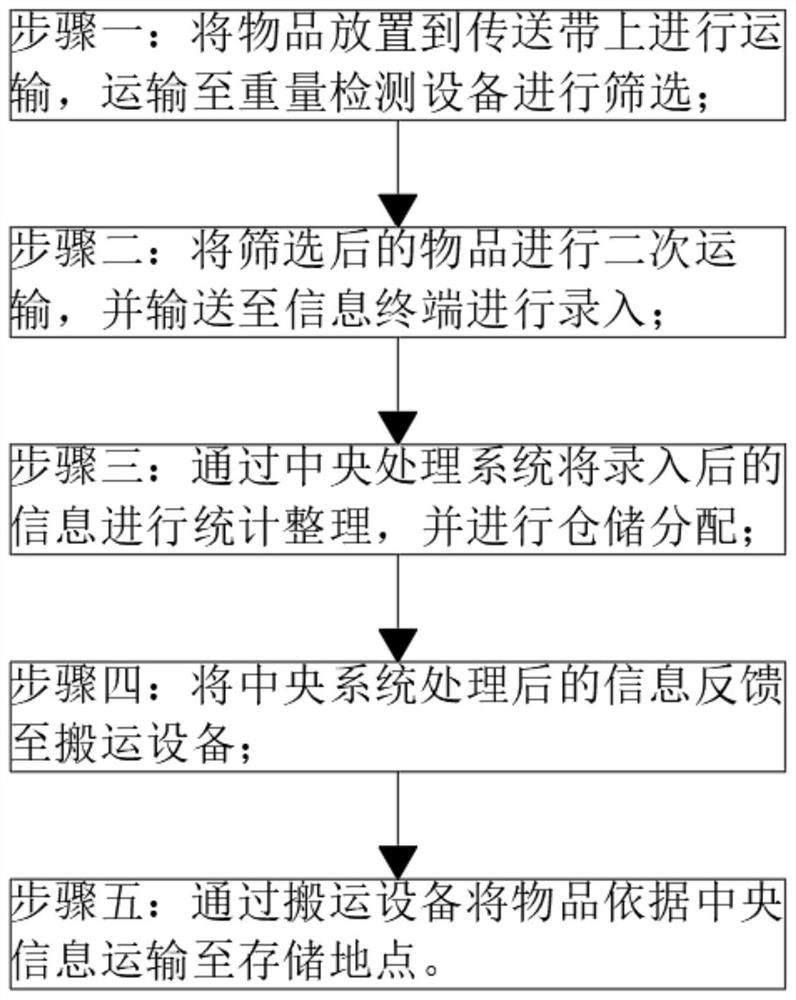

[0044] see figure 1 , the present invention provides a technical solution: a logistics warehouse management system, comprising the following steps:

[0045] Step 1: Place the items on the conveyor belt for transportation, and transport them to the weight detection equipment for screening;

[0046] Step 2: Carry out secondary transportation of the screened items and send them to the information terminal for input;

[0047] Step 3: Statistically organize the entered information through the central processing system, and perform storage allocation;

[0048] Step 4: Feedback the information processed by the central system to the handling equipment;

[0049] Step 5: Transport the items to the storage location through the handling equipment according to the central information. Through the weight detection equipment, the items are classified according to the weight of the stored items, and the subsequent items are classified and transported, so as to avoid the uniformity of the h...

Embodiment 2

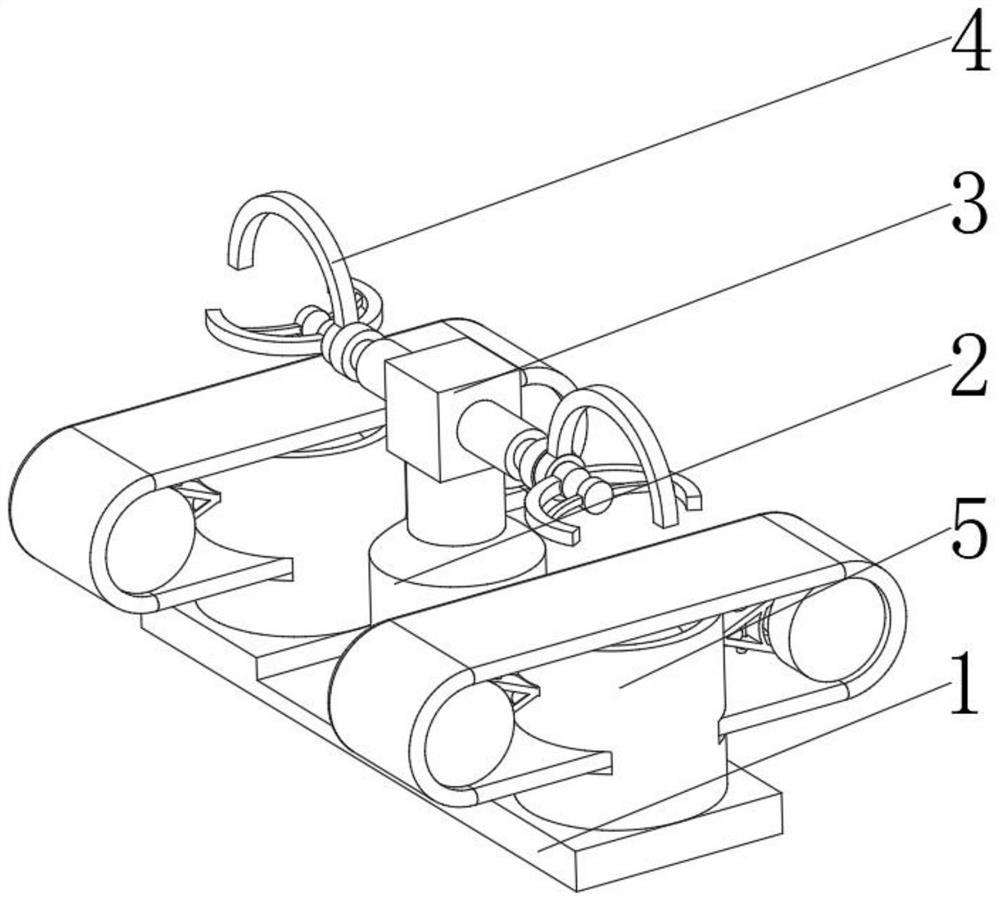

[0051] see figure 2 , 3 , 5. The present invention provides a technical solution: a logistics warehousing and storage device, and the weight detection device specifically includes:

[0052] Base 1, the base 1 base has a rectangular base, and a hydraulic cylinder 2 installed in the middle of the top of the rectangular base, a rotator 3 installed on the top of the hydraulic cylinder 2, and a transposition installed on the front and back of the rotator 3 Mechanism 4, and the detection mechanism 5 installed on the top of the rectangular seat and located on the front and back of the hydraulic cylinder 2, adjusts the height of the components through the design of the hydraulic cylinder 2. Because the fluid transmission itself has a high degree of lubrication, the components are difficult to wear, and at the same time The properties of its own liquid are less affected by the temperature difference of the external environment and are suitable for a wide range of working environments...

Embodiment 3

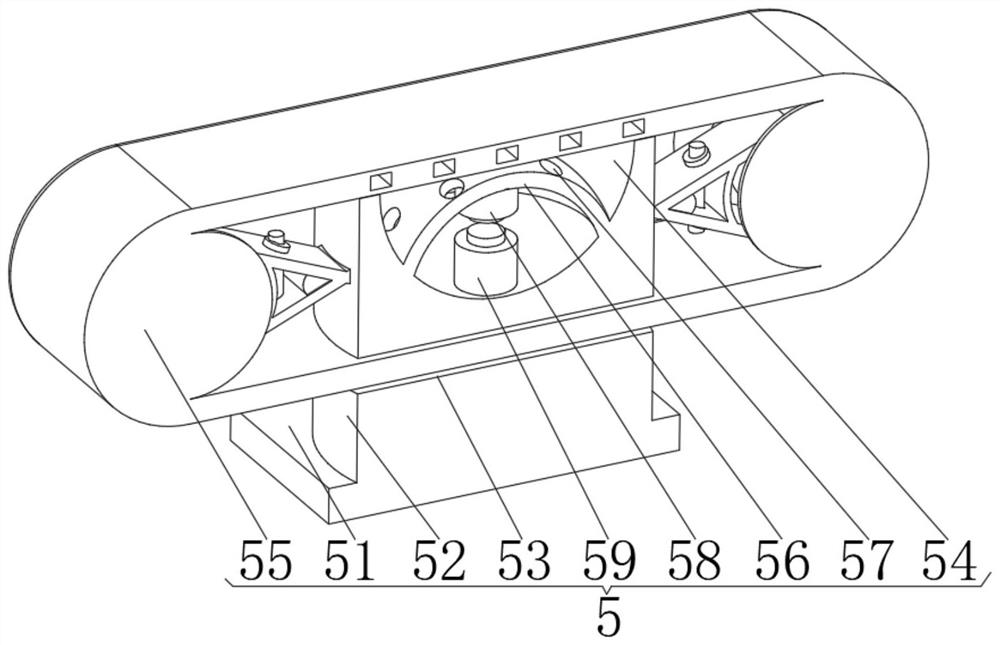

[0061] see Figure 2-5 , on the basis of Embodiment 1, the present invention provides a kind of technical scheme: transfer mechanism 55 comprises:

[0062] Adjusting frame 551, the adjusting frame 551 has a V-shaped frame body, and a magnetic block 552 installed at the corner position of the inner surface of the V-shaped frame body, and a lock post 553 installed in the middle of the V-shaped frame body, and installed on the V-shaped frame body The arc plate 554 on the side of the lock post 553 away from the magnetic block 552, and the sleeve band 555 installed on the open end of the V-shaped frame body, and the rotating motor 556 installed on the inner surface of the sleeve band 555, and installed on the output end of the rotating motor 556 Rotating wheel 557, and the transfer belt 558 that is installed on the outer surface of rotating wheel 557. The transfer belt 558 itself is provided with magnetic blocks at intervals, and the items are transported through the rotation of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com