Manufacturing method of auricle corrector for ear boat shaping

A manufacturing method and technology of orthotics, which are applied in medical science and other fields, can solve problems such as large contact area between adhesive plaster and skin, difficulty in inserting silicone sleeves, aggravation of baby eczema, etc., to reduce the occurrence probability of eczema, small contact range, and easy to use. tinsel effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0038] A manufacturing method of an auricle corrector for scaphoid shaping, comprising the following steps:

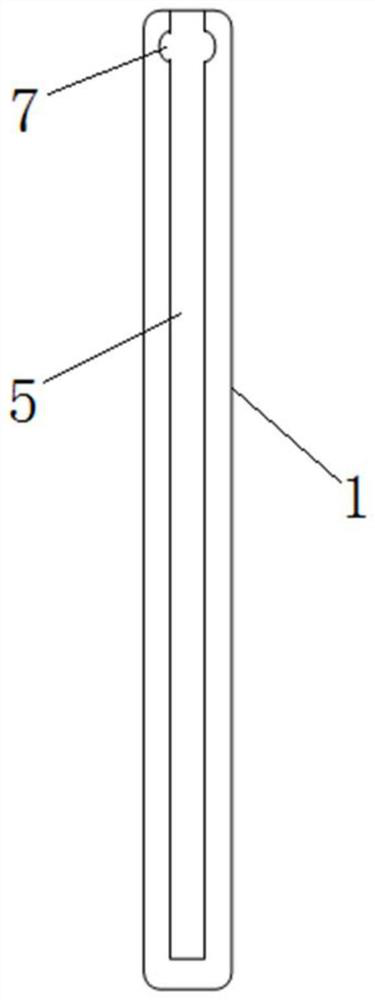

[0039] 1) if figure 1 As shown, select the outer tube 1 that is open at the top, closed at the bottom and bendable, pre-coat the outer surface of the outer tube 1 with an adhesive layer 4, and wrap the release paper outside the adhesive layer 4; select the appropriate thickness, quantity, and material The metal wire 2 is inserted into the outer tube 1 from the top opening of the outer tube 1, and placed in the wire placement cavity 5 in the outer tube 1;

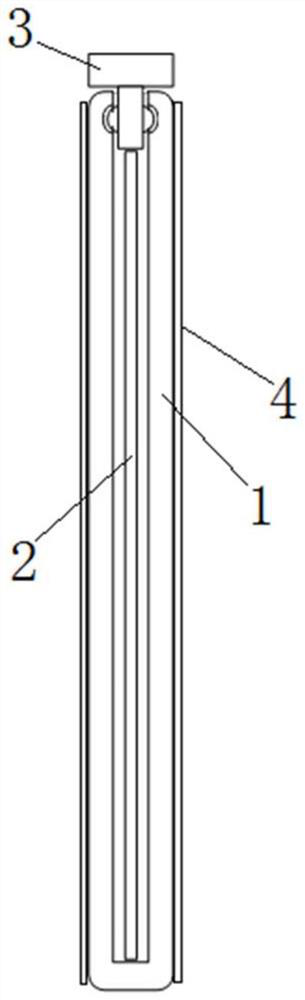

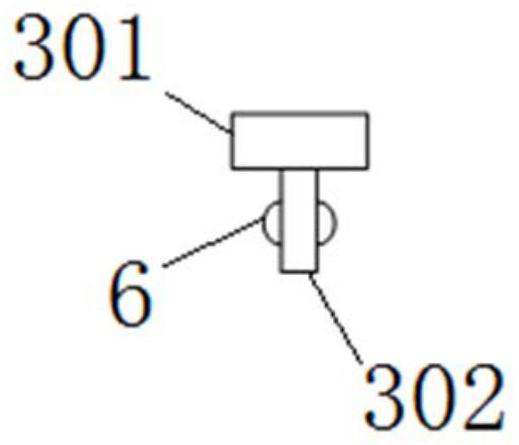

[0040] 2) if figure 2 As shown, the top end of the outer tube 1 is closed with the plug 3, and the elastic bump 6 is snapped into the slot 7;

[0041] 3) The outer tube 1 and the metal wire 2 are bent to a predetermined curvature to obtain the auricle corrector. The release paper is peeled off during use, and then the auricle corrector is placed in the scaphoid of the child, and is directly pasted in the scaphoid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com