Chair leg packaging and using method

A chair foot and packaging technology, which is applied to chairs, applications, household appliances, etc., to achieve the effect of high safety factor, convenient self-installation, and convenient and quick installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

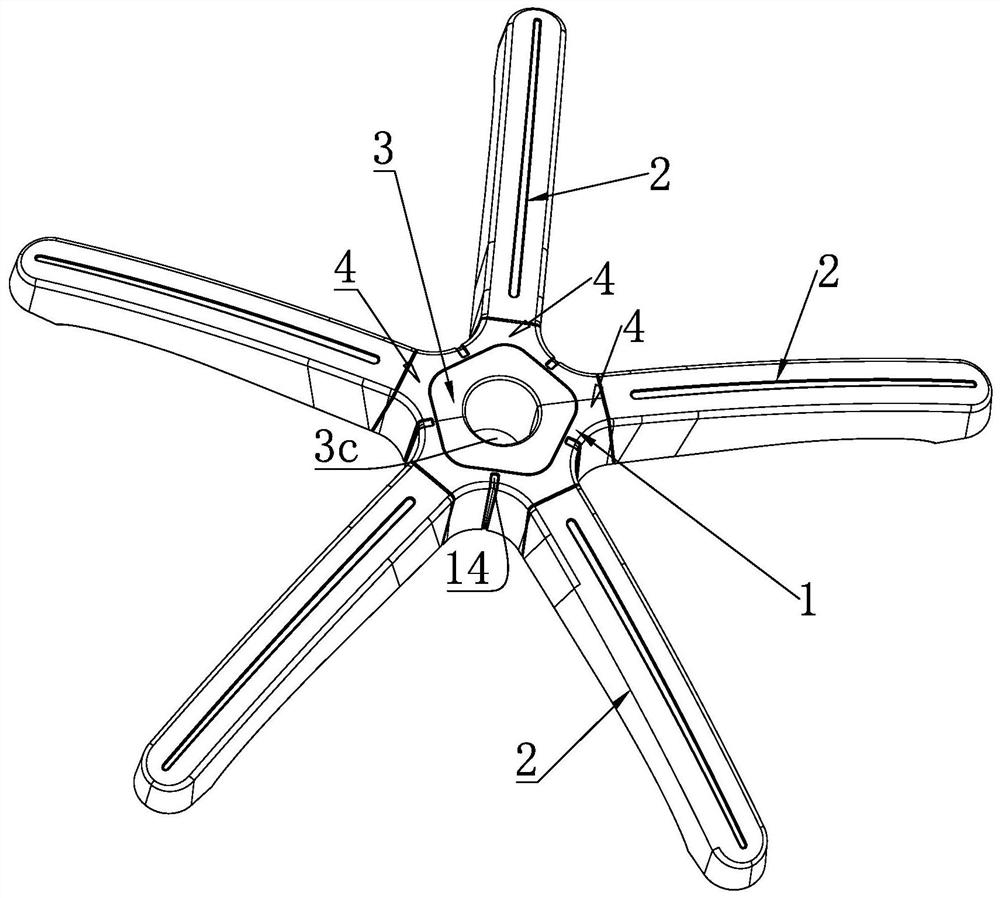

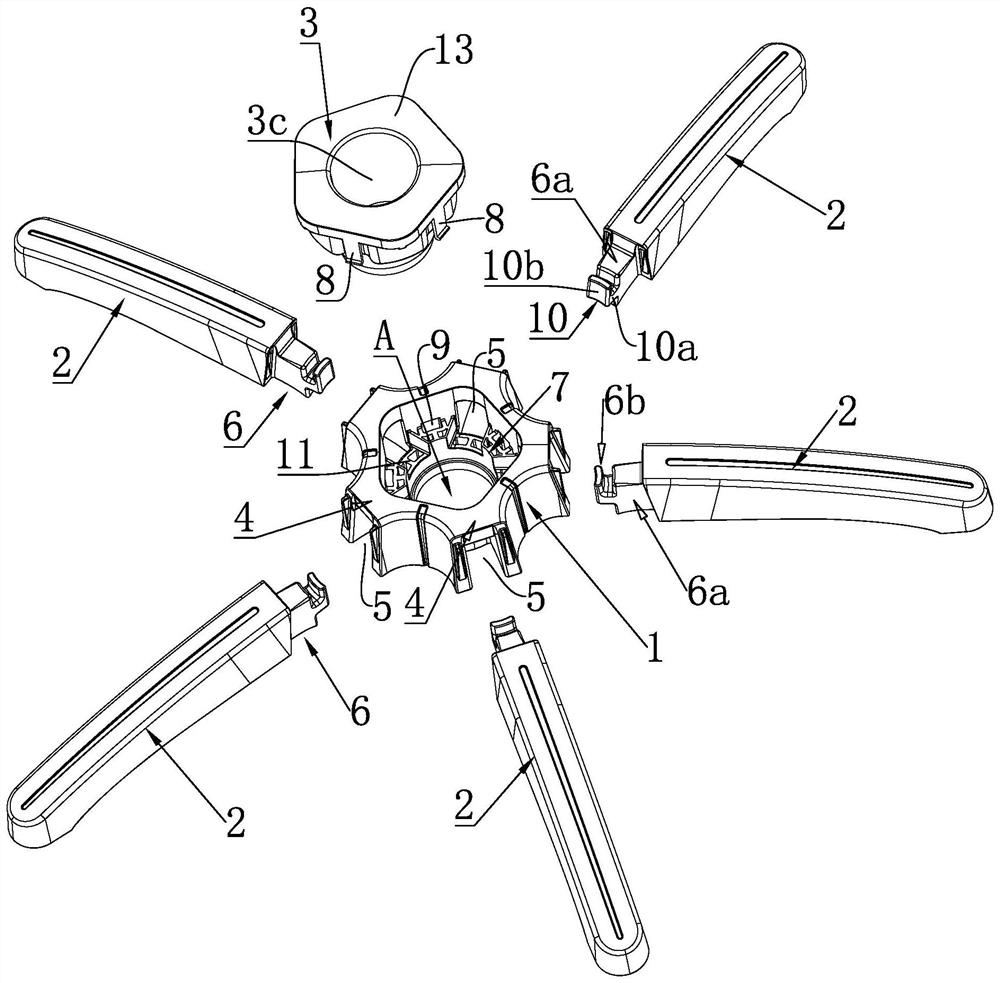

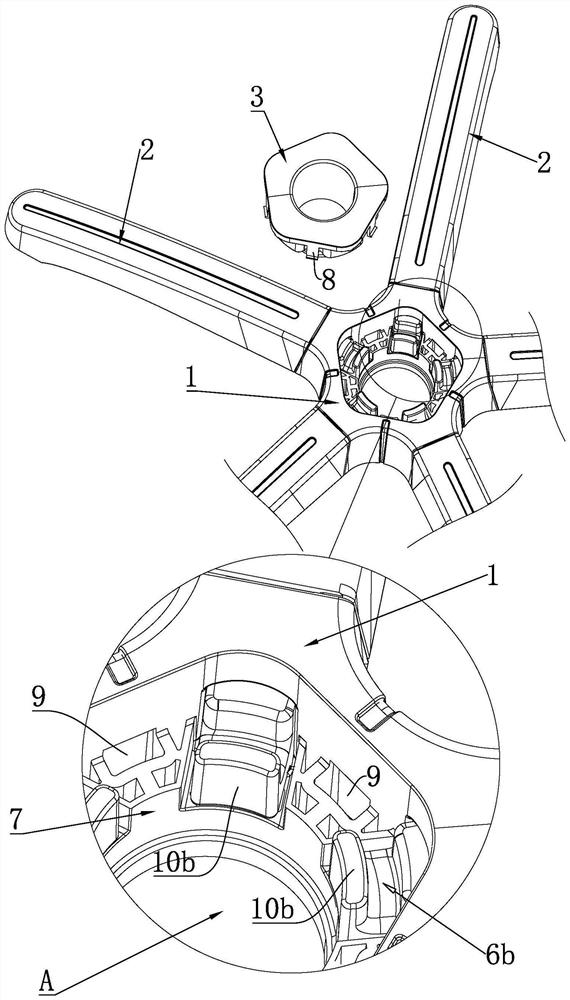

[0049] Embodiment 1: as Figure 1-10 As shown, the present invention provides a method for packaging and using chair legs, wherein the chair legs include a connection base 1, a chair foot unit 2 and a central clip 3; There are hollow parts A hollowed out up and down, and the connecting base 1 includes splicing parts 4 arranged at uniform intervals along its circumferential direction, and the splicing parts 4 protrude outward relative to the connecting base 1 . The chair leg unit 2 is configured to be detachably connected to the splicing part 4, and the number of the chair leg unit 2 is configured to be the same as the number of the splicing part 4; in this embodiment, the chair leg structure is specifically a general The five-pointed star-shaped chair foot, so the number of the chair foot unit 2 and the number of splicing parts 4 are five. On the end surface of each splicing part 4 away from the center direction of the connecting base 1, there is a mounting groove 5 through t...

Embodiment 2

[0067] Embodiment 2: as Figure 11-12 As shown, the difference between this embodiment and Embodiment 1 is that: the notch contour of the hollow part A located at the upper end of the connecting base 1 is set to be circular, and correspondingly, the upper cover plate 13 is also set to match it Matching circular structure. And the upper cover plate 13 is provided with an outwardly protruding positioning block 15, and a positioning groove 16 is correspondingly provided on the upper end surface of the connecting base 1; when connecting, it is only necessary to align the positioning block 15 with the positioning groove 16 and then After the central clip 3 is inserted into the hollow portion A, it can be clipped with the connecting base 1 . And in this embodiment, when packaging and transporting, the chair leg unit 2 , the connecting base 1 and the center clip 3 need to be disassembled and packaged for transport. At this time, it is not possible to place the central clip 3 in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com