a lifting column

A technology of lifting columns and columns, which is applied to the legs of general furniture, tables with variable table heights, household appliances, etc., can solve the problems of cumbersome installation process, difficult operation, poor user experience, etc., and achieve simple and convenient installation, The effect of stable structure and easy self-installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

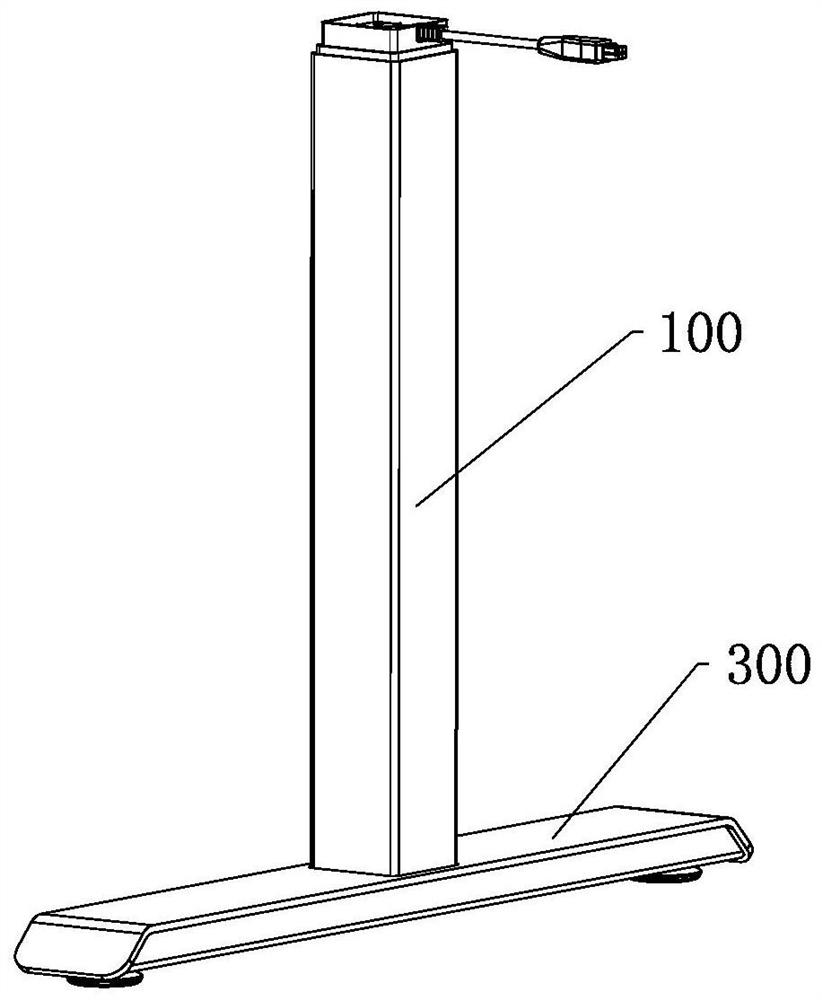

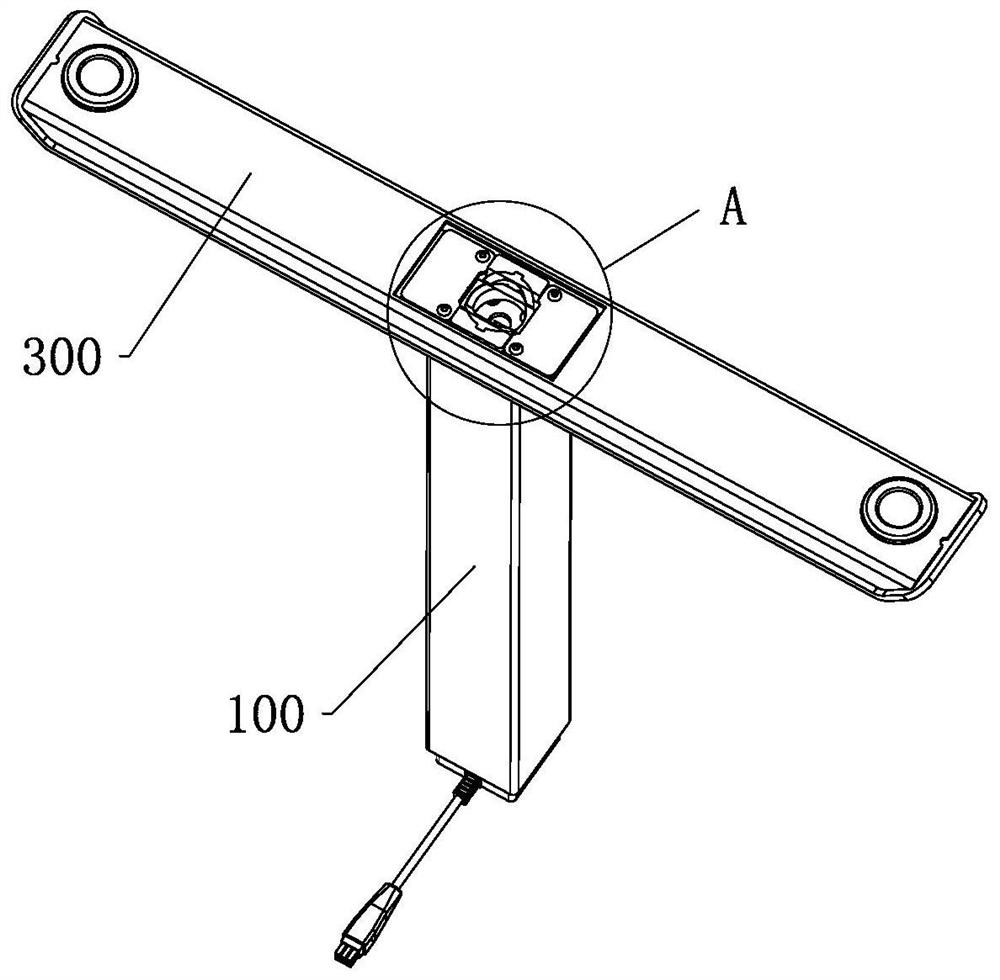

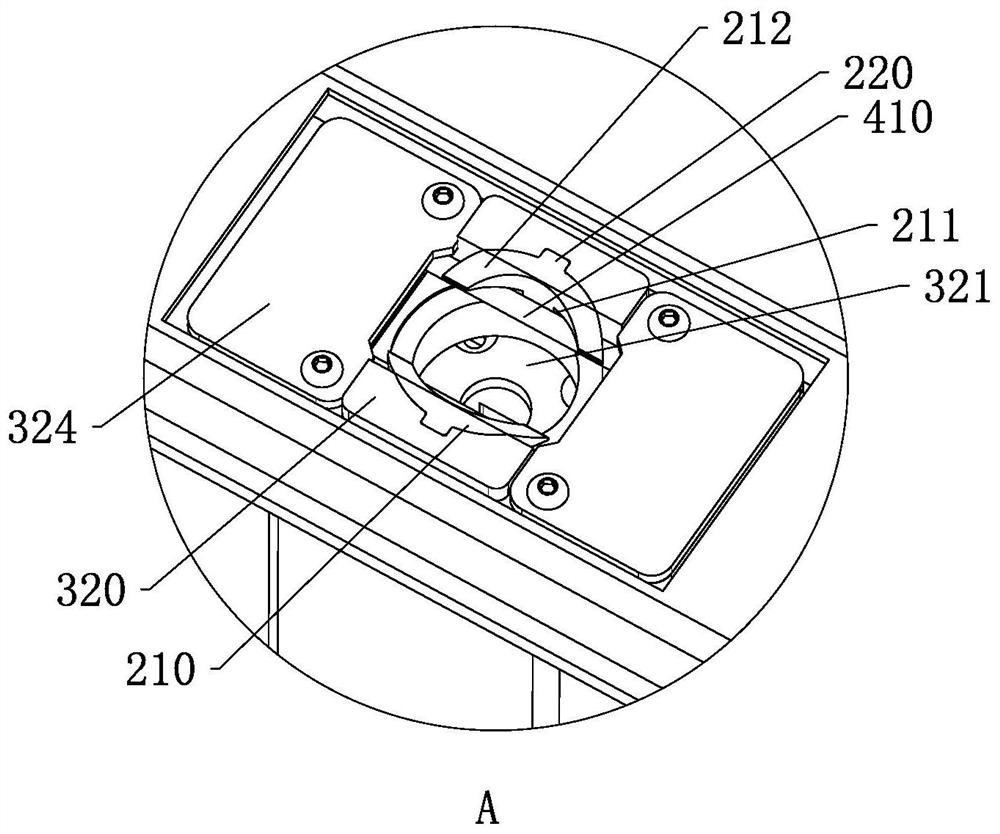

[0037] A lifting column, such as Figure 1 to Figure 10 As shown, it includes a column 100 and a foot 300 installed at the bottom of the column 100. A socket 200 is provided at the bottom of the column 100, a card slot 211 is provided on the socket 200, and a socket 211 is provided on the foot 300. The socket 321 of the socket 200 and the elastic clamping assembly 400 located at the lower part of the socket 321, when the column 100 is installed on the stand 300, align the socket 200 at the bottom of the column 100 with the socket 321 and insert it toward the socket 321. It can be plugged in the hole 321. During the plugging process, the connector 200 forms a squeeze on the elastic clamping component 400 in the socket 321 to push the elastic clamping component 400 away. When the connector 200 is installed in place, The elastic clamping assembly 400 resets under the action of the elastic force to be clamped in the slot 211 of the connector 200, and the elastic clamping assembly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com