Leaf vegetable planting greenhouse

A greenhouse and leafy vegetable technology, applied in the field of vegetable planting, can solve the problems of poor thermal insulation effect, etc., and achieve the effects of slowing down the loss of temperature, ensuring normal growth, and increasing the effect of thermal insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

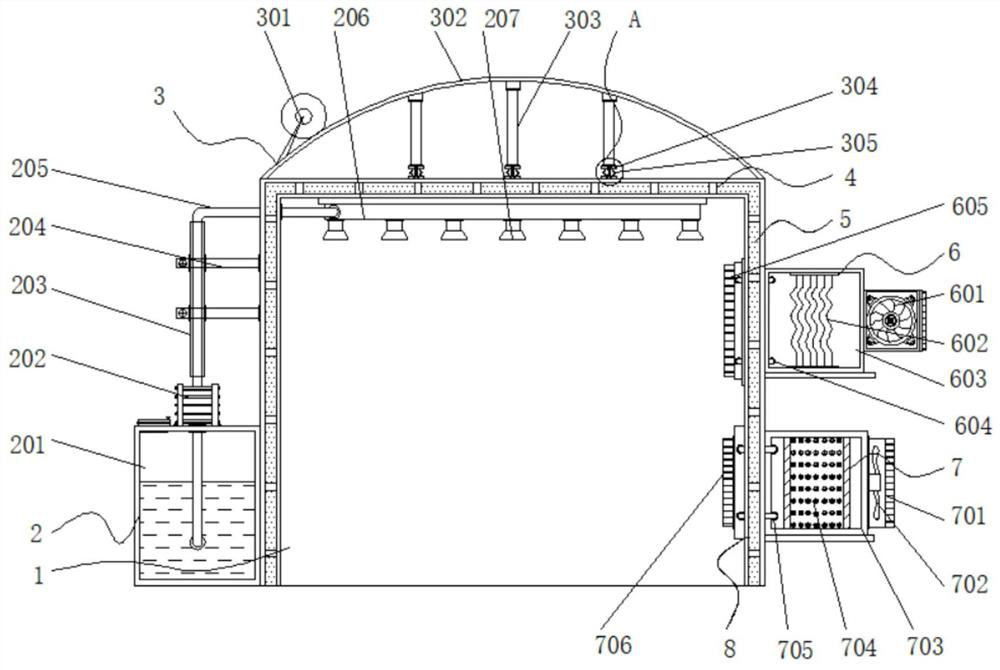

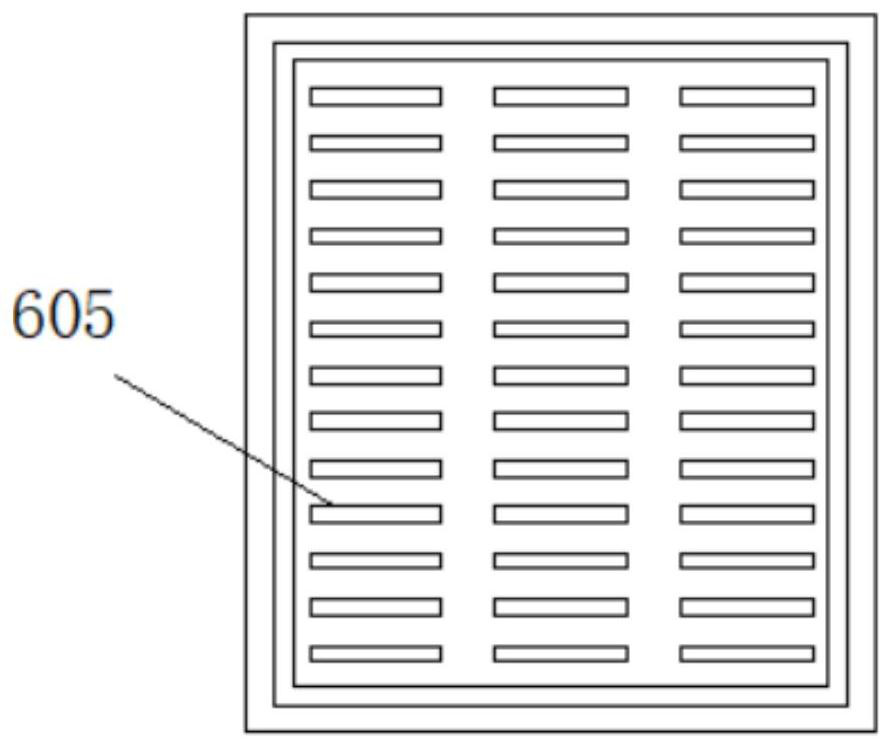

[0035] Example 1: See Figure 1-6 , a leaf vegetable planting greenhouse, comprising a greenhouse main body 1, a spray mechanism 2 is provided at the bottom of one side of the greenhouse main body 1, a lighting mechanism 3 is provided at the top of the greenhouse main body 1, and a heating device is provided at the top of the other side of the greenhouse main body 1. Mechanism 6, the bottom end of the other side of the greenhouse main body 1 is provided with a purification mechanism 7, and the inner wall of the greenhouse main body 1 is provided with a thermal insulation structure;

[0036] see Figure 1-6 A leafy vegetable planting greenhouse further includes a thermal insulation structure, the thermal insulation structure includes an inner layer 8, the inner layer 8 is arranged on the inner wall of the greenhouse main body 1, and multiple groups of thermal insulation boards 4 are fixedly connected between the inner layer 8 and the greenhouse main body 1 , the thermal insulati...

Embodiment 2

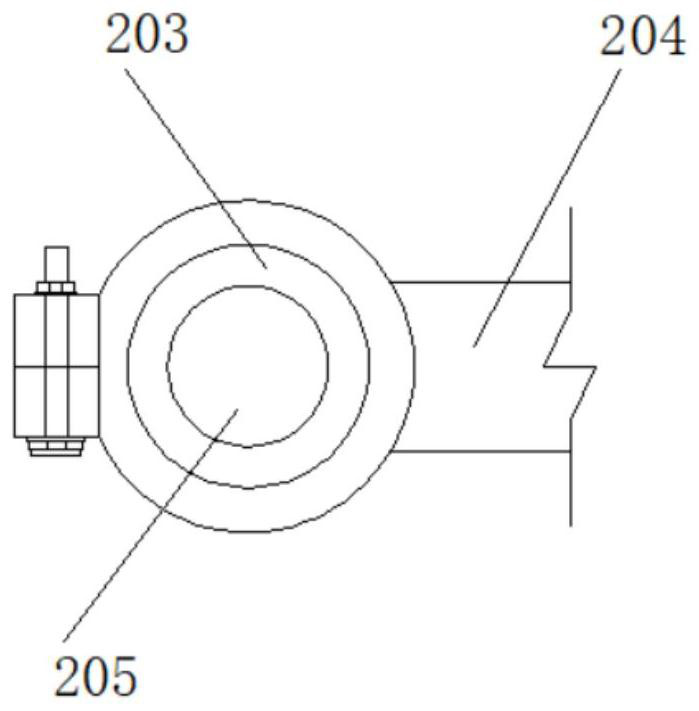

[0038] Embodiment 2: Sprinkler mechanism 2 is made up of water tank 201, water pump 202, insulation cover board 203, support frame 204, suction pipe 205, distribution pipe 206 and nozzle 207, and water tank 201 is arranged on the side of the bottom end of greenhouse main body 1, and water tank The inside of 201 runs through a suction pipe 205, and the top of the suction pipe 205 runs through the inside of the greenhouse main body 1 and communicates with the inside of the distribution pipe 206. The distribution pipe 206 is fixedly connected to the top inside the greenhouse main body 1, and the bottom end of the distribution pipe 206 is fixed. Connected with nozzles 207, the nozzles 207 are provided with seven groups, the size of the holes provided by the nozzles 207 is equal, the outside of the suction pipe 205 side is provided with a thermal insulation cover 203, and the external of the thermal insulation cover 203 is provided with two groups of support frames 204, the support f...

Embodiment 3

[0040] Embodiment 3: Daylighting mechanism 3 is composed of electric sunshade roller blind 301, hollow transparent composite daylighting panel 302, support rod 303, upper connecting plate 304, hinged rod 305, lower connecting plate 306, buffer spring 307 and movable sleeve block 308, hollow Both sides of the bottom end of the transparent composite daylighting panel 302 are fixedly connected to both sides of the top of the greenhouse main body 1, and the outer side of the hollow transparent composite daylighting panel 302 is provided with an electric sunshade roller blind 301. The model of the electric sunshade roller blind 301 can be JHLY- 00001, the bottom end of the hollow transparent composite lighting panel 302 is fixedly connected with three sets of support rods 303, the bottom end of the support rods 303 is fixedly connected with an upper connection plate 304, the length of the upper connection plate 304 and the lower connection plate 306 are equal, and the length of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com