Seed germination accelerating device capable of adjusting temperature and humidity

A technology for adjusting temperature and humidity, applied in germination equipment and other directions, can solve the problems of uneven seed humidification and heating, affecting normal seeding of seeds, slow seed germination, etc., to avoid shaking, improve efficiency, and humidify and heat the effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

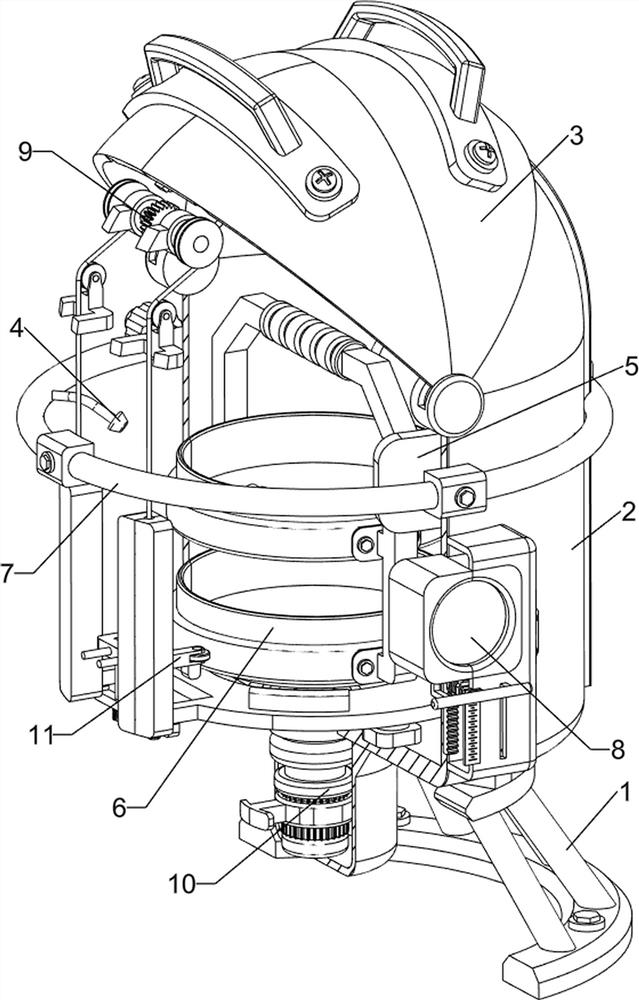

[0036] A seed germination device for regulating temperature and humidity, such as Figure 1-Figure 10 As shown, it includes a support frame 1, a casing 2, a discharge frame 201, a cover 3, an atomizing nozzle 4, a heating plate 5, a placement component 6, a humidity control component 7 and a temperature control component 8. The left and right sides of the bottom of the casing 2 are The support frame 1 is fixedly connected, the lower side of the shell 2 is installed with a placement component 6, and two discharge frames 201 are slidably placed on the placement component 6. Four atomizing nozzles 4 are installed evenly at intervals, a heating plate 5 is installed on the upper front side of the casing 2, a humidity control component 7 is installed on the middle part of the casing 2, and the humidity control component 7 is connected to the atomizing nozzle 4, and the lower front side of the casing 2 is installed Temperature control assembly 8 is arranged.

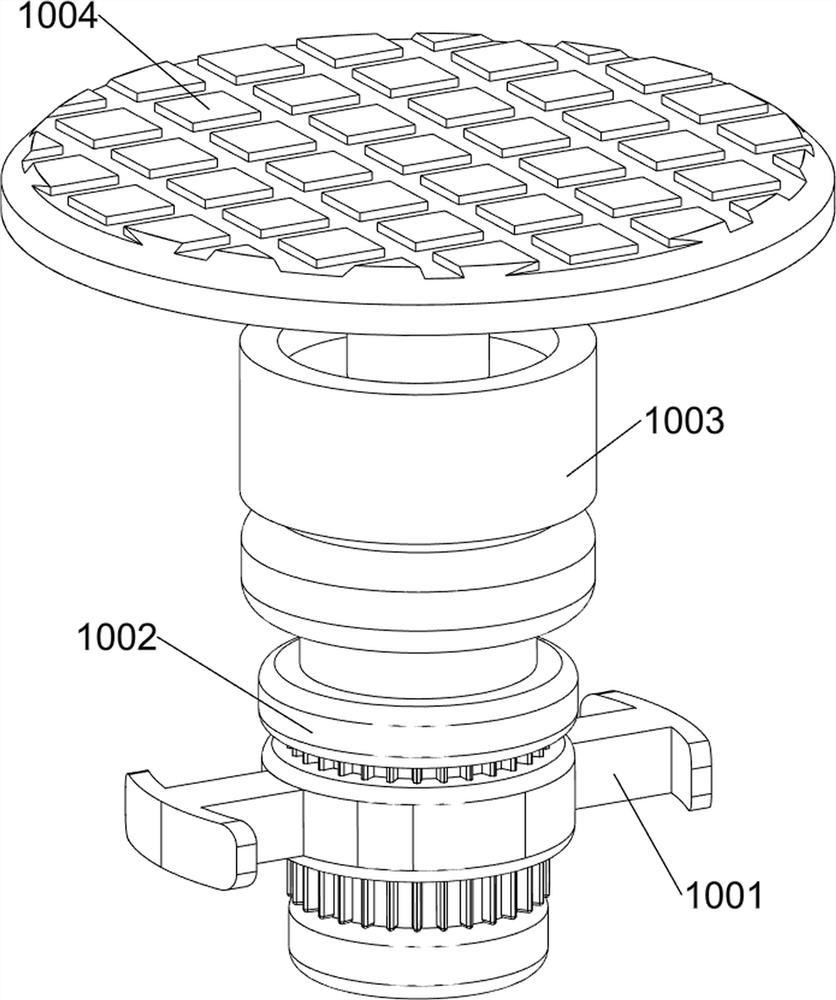

[0037] The placement ass...

Embodiment 2

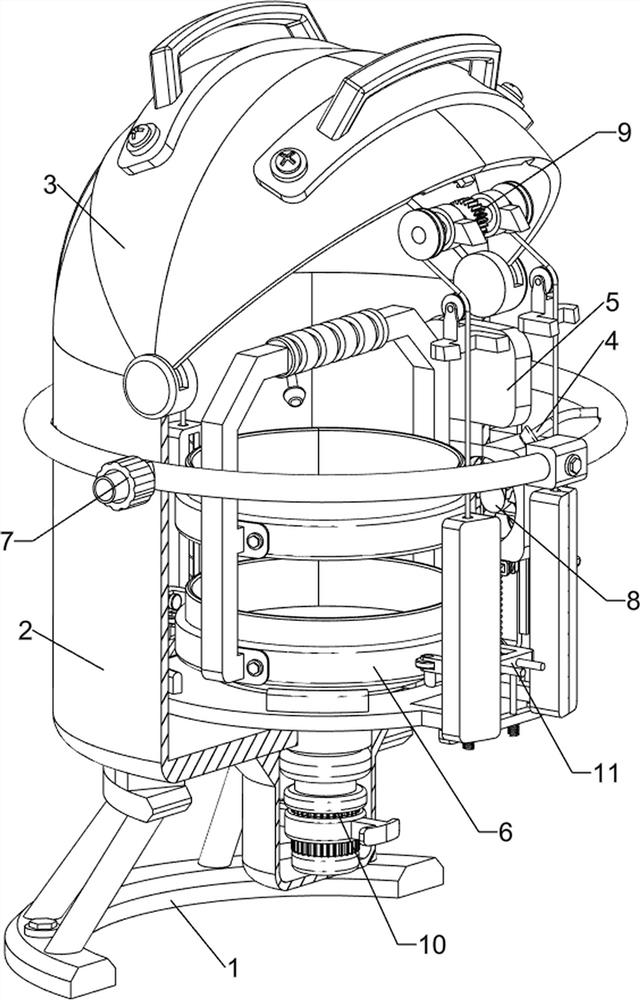

[0042] On the basis of Example 1, such as Figure 11-Figure 16 As shown, a lifting assembly 9 is also included, and the lifting assembly 9 includes a first support block 901, a gear 902, an arc rack 903, a winding wheel 904, a pulley 905 and a stay cord 906, and the left and right sides of the upper part of the housing 2 are A first support block 901 is fixedly connected front and rear symmetrically, and a gear 902 is rotatably connected between the first support blocks 901 on the front and rear sides, and an arc-shaped rack 903 is arranged on the inner side of the cover 3, and the arc-shaped rack 903 rotates with each other. Adjacent gears 902 mesh, and both sides of the front and back of the gear 902 are equipped with winding wheels 904, and the left and right sides of the inner upper part of the casing 2 are connected with pulleys 905 in a symmetrical rotation type, and the pulleys 905 are all located below the winding wheels 904. Both stay ropes 906 are connected between 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com