Rapid wet plugging electric connection structure

A technology of electrical connection structure and wet plugging, applied in the direction of connection, two-part connection device, parts of connection device, etc., can solve problems such as easy misoperation, equipment damage, contact pin electrolysis or short circuit, etc., and achieve high positioning accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

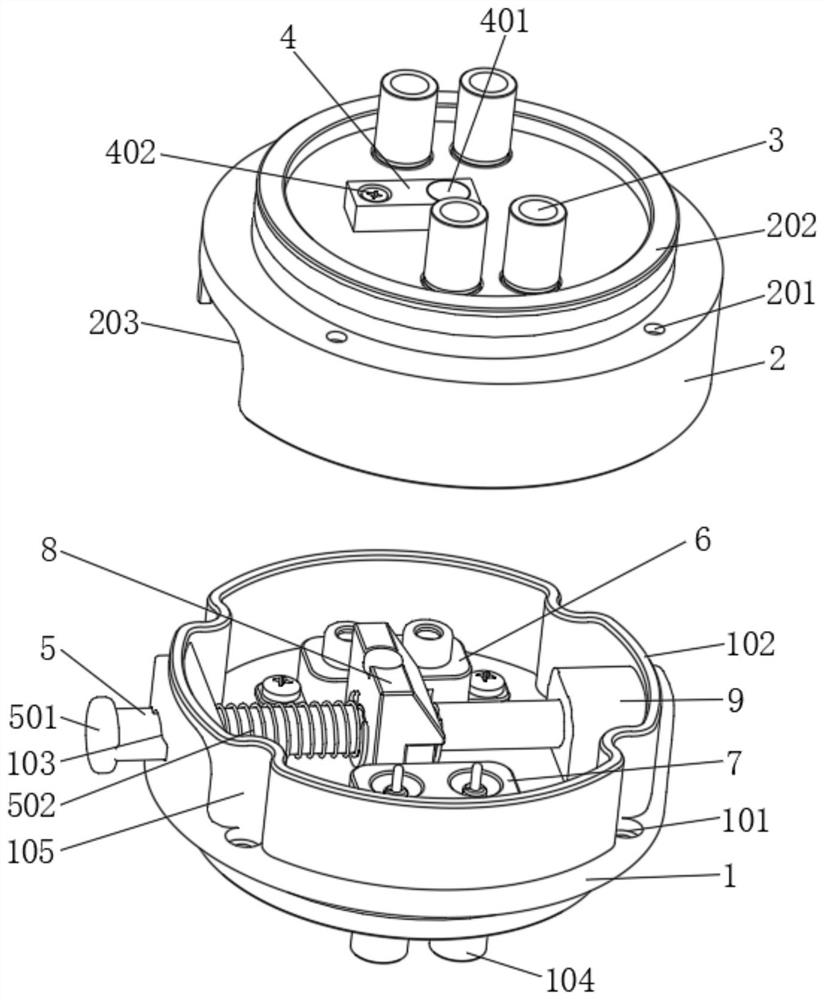

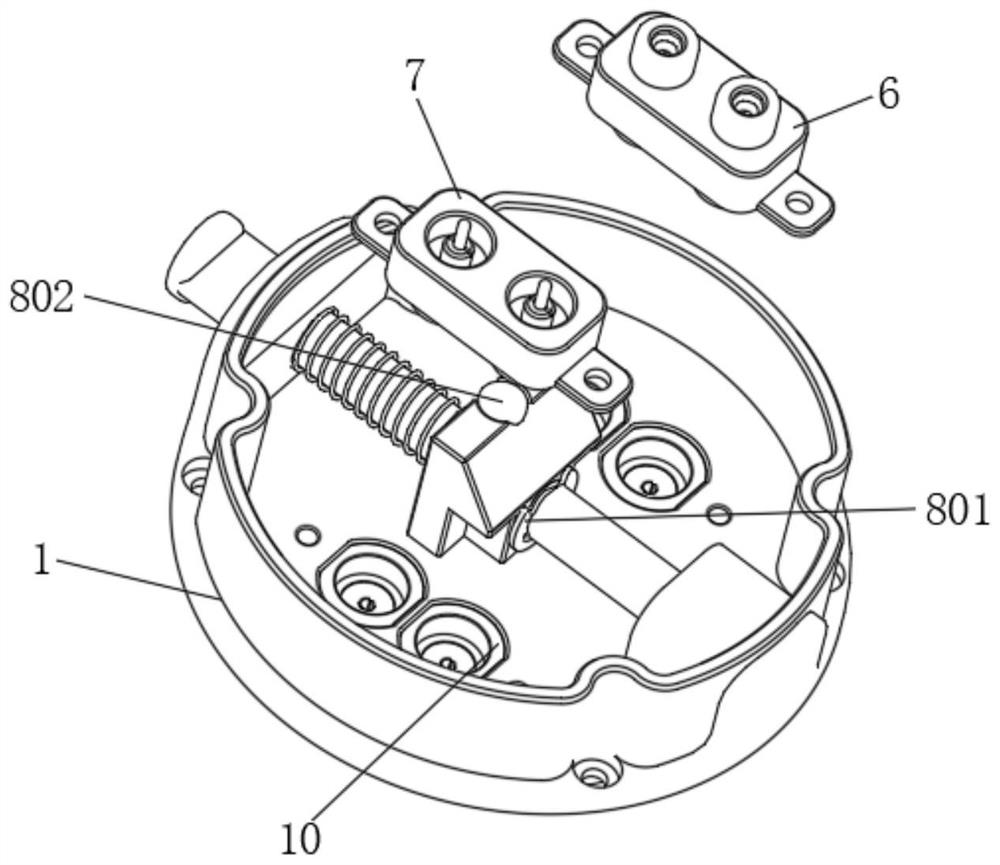

[0031] see Figure 1-6, a fast wet plug electrical connection structure, comprising a base 1, a cover shell 2 plugged into the top of the base 1, a connecting column 3 fixedly connected to the top of the cover shell 2, a magnetic induction switch 4 fixedly connected to the top of the cover shell 2, The inside of the base 1 is plugged with a plunger 5, the bottom of the plunger 5 is sleeved with a fixed block 9, and the inner bottom wall of the base 1 is provided with two quick-release head mounting seats 10, and the two quick-release head mounts 10 There are quick-release female head 6 and quick-release male head 7 respectively plugged inside. Both quick-release female head 6 and quick-release male head 7 are installed on the quick-release head mounting seat 10. Corrosion or damage may occur after long-term use , can directly replace the female head 6 of the quick release head and the male head 7 of the quick release head, which can solve the corrosion problem of the connector...

Embodiment 2

[0033] see Figure 1-4 , this embodiment provides a technical solution on the basis of Embodiment 1: a quick wet plug electrical connection structure, including a base 1, a threaded hole 101 is opened on the outside of the top of the base 1, and the top of the base 1 is fixedly connected There is a side wall 102, and a through hole 103 is opened at the position where the side wall 102 is in contact with the insertion rod 5. The bottom of the base 1 is fixedly connected with a connector 104, and the outer side of the side wall 102 is fixedly connected with a positioning block 105, and the top of the base 1 is plugged in. There is a cover shell 2, a positioning hole 201 is opened on the outside of the top of the cover shell 2, a socket 202 is fixedly connected to the top of the cover shell 2, and a positioning groove 203 is opened on the outside of the cover shell 2, through which the positioning groove 203 on the cover shell 2 and the base 1 The positioning block 105 on the top...

Embodiment 3

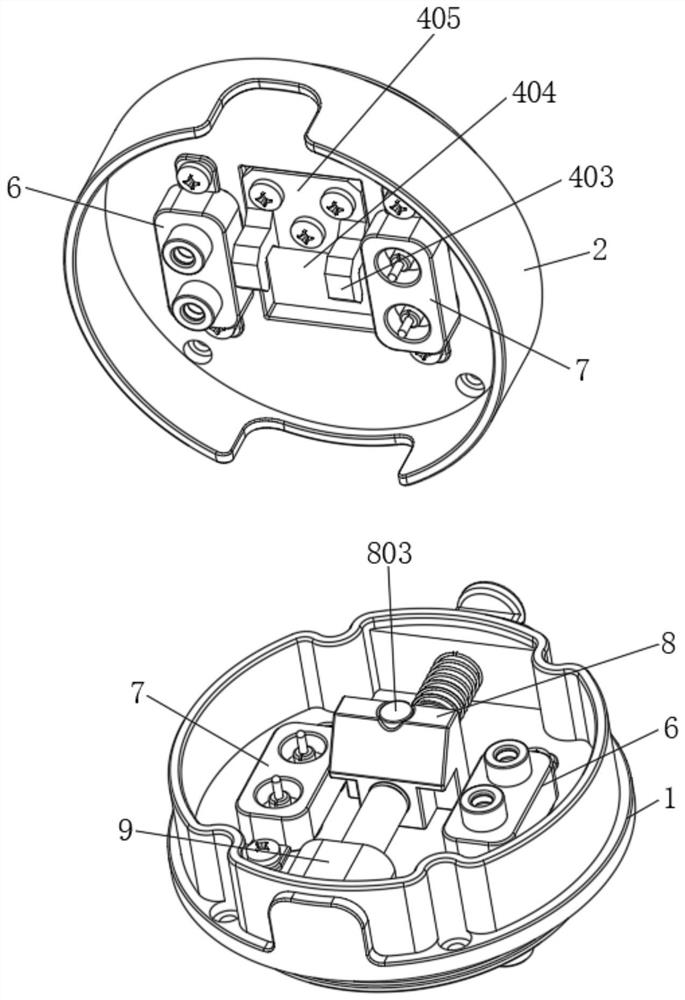

[0035] see Figure 1-4 , this embodiment provides a technical solution on the basis of Embodiment 1: a quick wet plug electrical connection structure, including a base 1, the top of the base 1 is plugged with a cover shell 2, and the top of the cover shell 2 is fixedly connected There is a connecting column 3, a magnetic induction switch 4 is fixedly connected to the top of the cover shell 2, a socket 401 is opened on the top of the magnetic induction switch 4, a fixing screw 402 is arranged between the magnetic induction switch 4 and the cover shell 2, and the inner top wall of the cover shell 2 The upper part is fixedly connected with a bottom plate 405 through fixing screws 402, and the bottom of the bottom plate 405 is symmetrically fixedly connected with two vertical plates 403, and a paddle 404 is rotatably connected between the two vertical plates 403, and the bottom of the magnetic induction switch 4 runs through the top of the cover shell 2 Afterwards, it is fixedly c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com