Indoor and outdoor universal self-supporting rubber-covered wire optical cable

A sheathed optical cable and self-supporting technology, applied in the field of indoor and outdoor self-supporting self-supporting optical cable, can solve the problems of short service life, high maintenance cost, increased loss, etc., so as to improve the anti-pressure performance and ensure the tensile strength. The effect of satisfying performance and bending performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

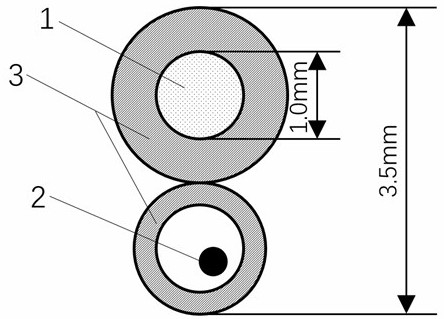

[0049] Such as figure 1 As shown, the self-supporting leather optical cable provided in this embodiment includes a strengthening member, a communication optical unit and an outer sheath;

[0050] The reinforcement is phosphating thick steel wire with a diameter of 1 mm; the reinforcement is placed straight;

[0051] The communication optical unit is a single-core tight-buffered optical fiber; the strengthening member is arranged in a straight line with the communication optical unit;

[0052] The outer sheath is 8-shaped; one side of the reinforcement is close to the outside of the phosphating thick steel wire, with a thickness of 0.5mm, and the radius of curvature of the arc on the side of the reinforcement is 1.0mm; the thickness of the side of the communication optical unit is 0.25mm. mm, forming a cavity with a diameter of 1mm to accommodate the communication optical unit, that is, covering the outside of the communication optical unit, and the radius of curvature on one ...

Embodiment 2

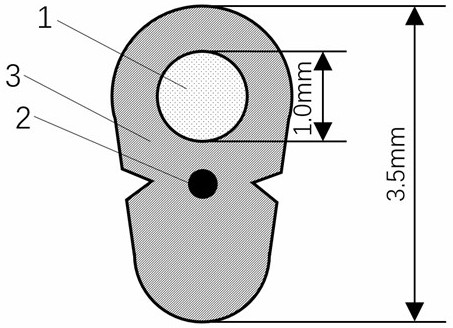

[0056] Such as figure 2 As shown, the self-supporting leather optical cable provided in this embodiment includes a strengthening member, a communication optical unit and an outer sheath;

[0057] The reinforcement is phosphating thick steel wire with a diameter of 1 mm; the reinforcement is placed straight;

[0058] The communication optical unit is a single-core tight-buffered optical fiber; the strengthening member is arranged in a straight line with the communication optical unit;

[0059] The outer sheath has a drop-shaped cross section, and the circle where the arc on one side of the reinforcing member is located is tangent to the circle where the arc on one side of the communication optical unit is located. The radius of curvature of the arc on one side of the reinforcement is 1.0mm, and the radius of curvature on the side of the communication optical unit is 0.75mm. There is a groove in the middle of the outer tangent section for optical cable stripping; The side is ...

Embodiment 3

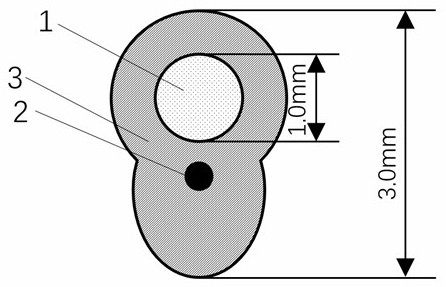

[0063] Such as image 3 As shown, the self-supporting leather optical cable provided in this embodiment includes a strengthening member, a communication optical unit and an outer sheath;

[0064] The reinforcement is phosphating thick steel wire with a diameter of 1 mm; the reinforcement is placed straight;

[0065] The communication optical unit is a single-core tight-buffered optical fiber; the strengthening member is arranged in a straight line with the communication optical unit;

[0066] The outer sheath has a gourd-shaped cross section, and the circle where the arc on one side of the reinforcing member is located and the ellipse circumference where the elliptical arc on one side of the communication optical unit is located form the outer periphery of the cross section, and the radius of curvature of the arc on the side of the reinforcing member is 1.0mm, the radius of curvature on one side of the communication optical unit is 0.75mm, the ellipse where the ellipse arc on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com