Adhesion testing device and method for coating layer of tin-plated steel sheet

A technology of electroplated tin-plated steel sheet and inspection device, which is applied to the device for coating liquid on the surface, the use of mechanical devices, coatings, etc., which can solve the problems of inaccurate sample detection results, inconvenient sample taking and placing, and inaccurate detection. To achieve the effect of improving market competitiveness, convenient classification and placement, and accurate detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

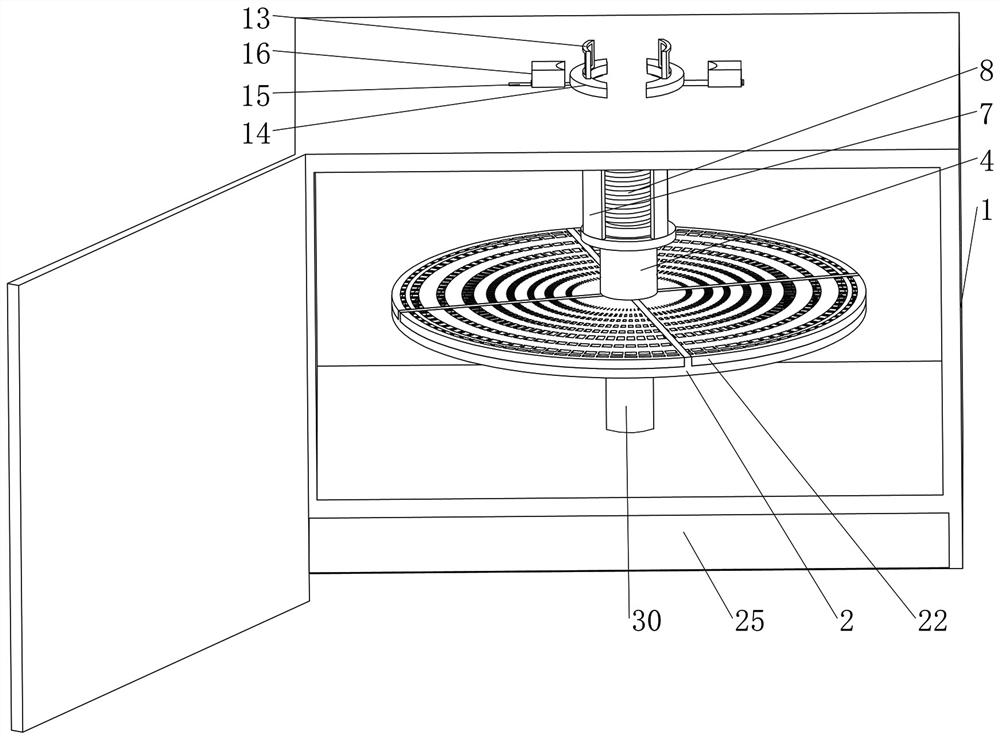

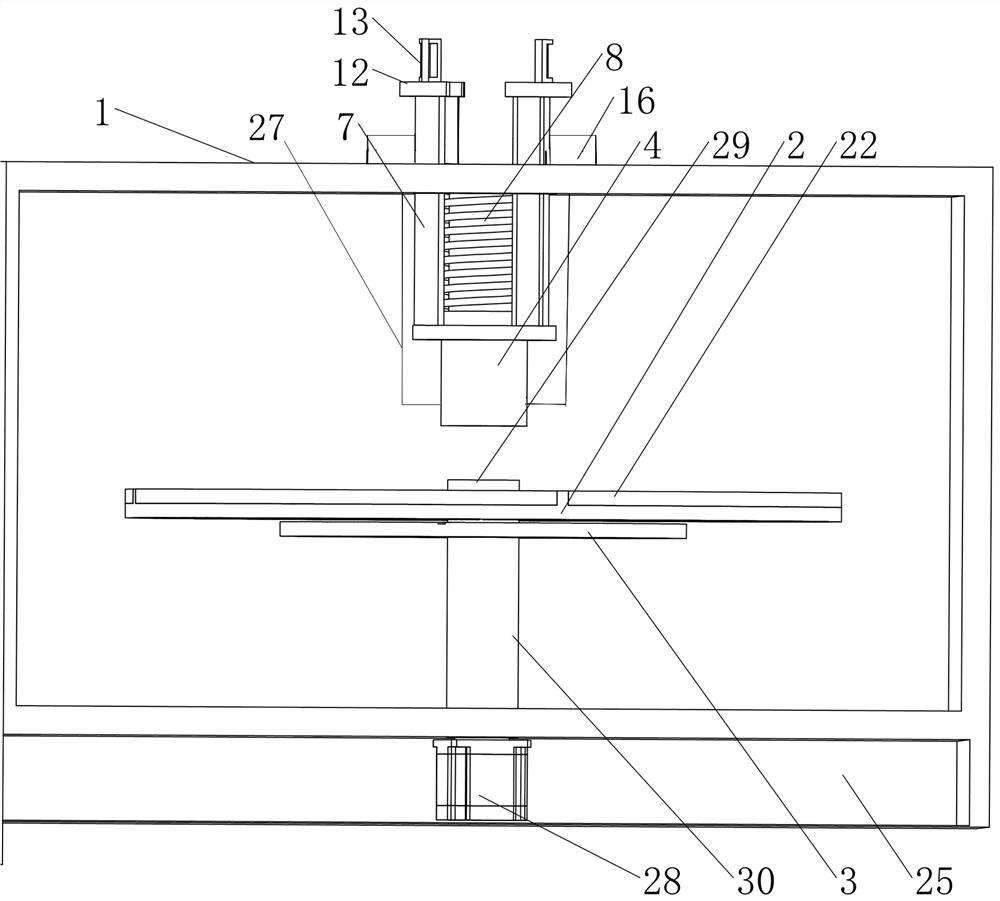

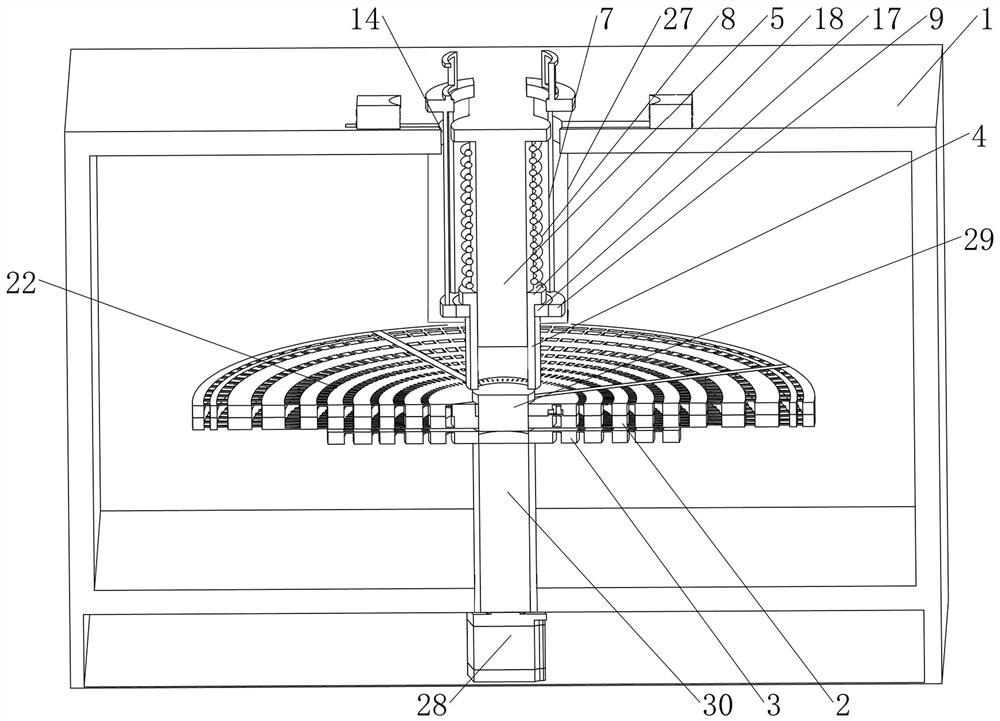

[0032] like Figure 1-Figure 5 As shown in the figure, the present invention proposes an adhesion inspection device for the coating layer of electroplated tin steel sheet, comprising an oven 1, a storage tray 2 is rotated inside the oven 1, and a rotating device is arranged below the storage tray 2, above which A fixing device is provided. The rotating device includes a turntable 3 and a power part arranged under the turntable 3. The power part drives the turntable 3 to rotate. The matching connection hole 19, the storage tray 2 is placed directly above the turntable 3, and the central connection hole 19 is sleeved on the outside of the central shaft 29; the fixing device includes a sleeve 4 and a vertically arranged fixing shaft 5, the fixing shaft 5 and the central shaft 29 are arranged coaxially, the top of the fixed shaft 5 is fixed on the top wall of the oven 1, the center of the sleeve 4 is provided with a vertical through hole, the sleeve 4 is sleeved on the outside of ...

Embodiment 2

[0045] like Figure 1-Figure 5 As shown, a method for inspecting the adhesion of the coating layer of electroplated tin steel sheet, using the adhesion inspection device for the coating layer of electroplated tin steel sheet in Embodiment 1, comprising the following steps:

[0046] S1. Place the samples to be tested in the corresponding baking trays 22 in sequence according to their respective classifications, and place the baking trays 22 on the storage tray 2 correspondingly.

[0047] S2. Pull the pulling part upwards to move the sleeve 4 upward, then place the storage tray 2 on the turntable 3, and then release the pulling part, the sleeve 4 moves down and presses the storage tray 2, and the storage tray 2 is attached to the turntable 3; start the oven 1 and the stepping motor 28, the turntable 3 drives the storage tray 2 to rotate synchronously, wherein the baking temperature is 215 ° C, and the baking time is 24 minutes; wherein the specific use method of the oven 1 is as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com