Hydrogen liquefying device for hydrogen production

A liquefaction device, hydrogen technology, applied in refrigeration and liquefaction, liquefaction, solidification, etc., can solve the problems of hydrogen liquefaction, immature storage technology, etc., and achieve the effect of compact structure, less load, and reasonable energy distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

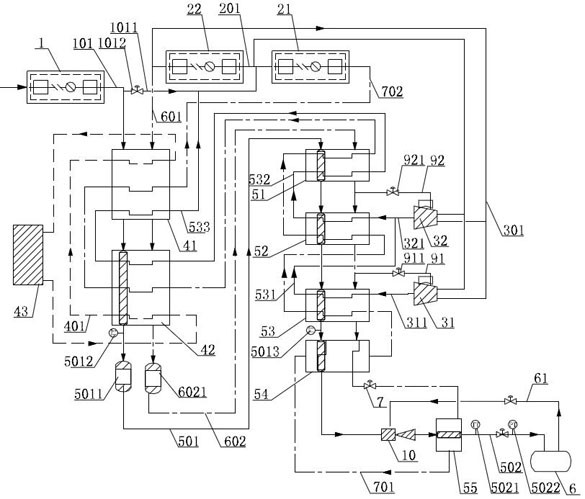

[0029] like figure 1 As shown, the hydrogen liquefaction device for hydrogen production includes: raw material hydrogen compressor 1, primary circulating hydrogen compressor 21, secondary circulating hydrogen compressor 22, low pressure turbo expander 31, medium pressure turbo expander 32 , primary pre-cooling heat exchanger 41, secondary pre-cooling heat exchanger 42, primary liquefaction cooler 51, secondary liquefaction cooler 52, third-stage liquefaction cooler 53, fourth-stage liquefaction cooler 54, fifth-stage liquefaction Cooler 55, liquid hydrogen storage tank 6. A circulating hydrogen compression delivery pipe 201 is connected between the primary circulating hydrogen compressor 21 and the secondary circulating hydrogen compressor 22 .

[0030] Each stage of the pre-cooling heat exchanger is equipped with a product hydroge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com